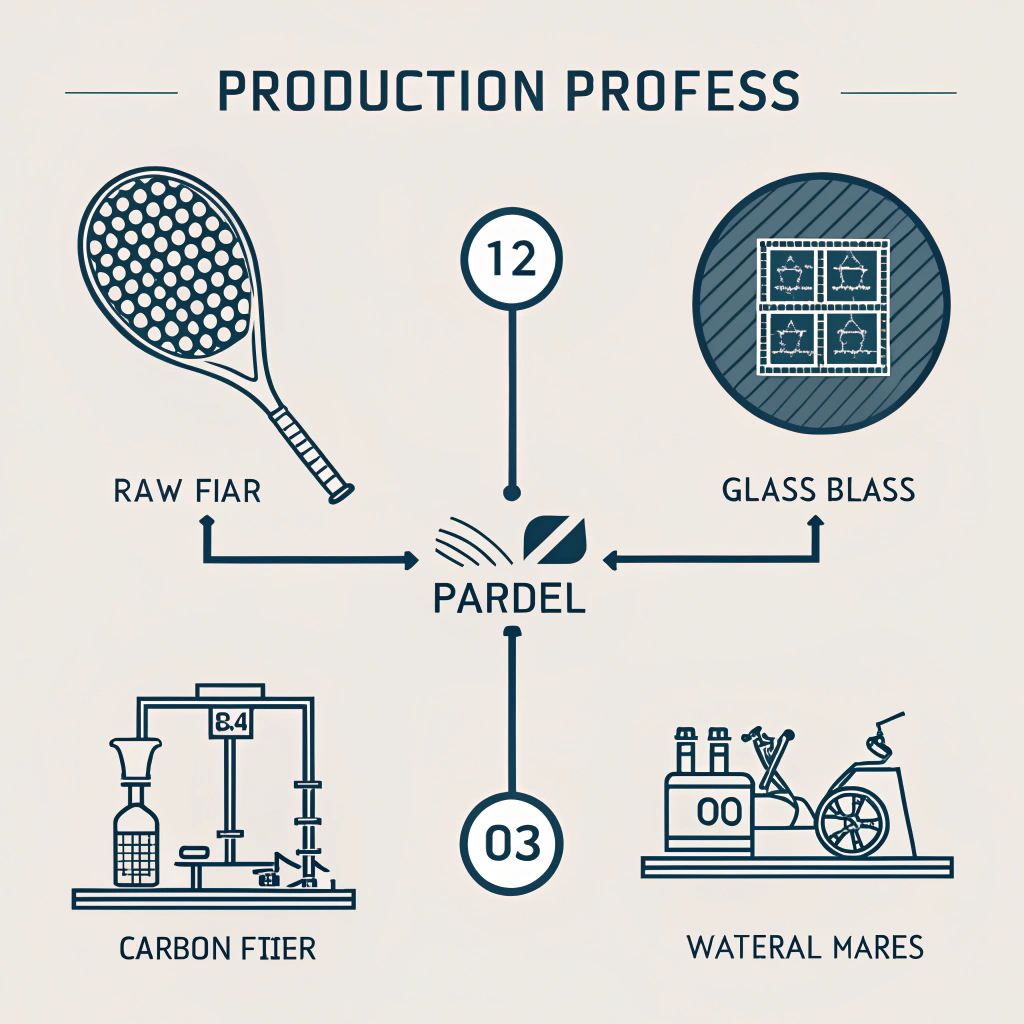

A quick answer: Custom padel racket pricing is determined by a complex mix of material costs, labor expenses, advanced production techniques1, and customized options such as shape, printing, and specialized components. Understanding each cost element in detail helps procurement managers compare suppliers and make informed sourcing decisions.

In today’s competitive sports equipment market, procurement managers and business owners must navigate a comprehensive cost structure to ensure they partner with manufacturers who offer the right blend of quality and value. When it comes to custom padel rackets, the production cost breakdown includes a variety of elements from raw materials like carbon fiber2 and glass fiber3 to labor costs and customization fees. By understanding these cost drivers, you can efficiently compare suppliers, such as NEX Padel, and justify your investment decisions with clear, data-driven insights.

Many buyers struggle with identifying which cost factors are the most significant when comparing padel racket suppliers. The challenge lies in distinguishing the impact of material quality, production techniques, and additional customizations on the overall pricing. A detailed cost breakdown often reveals hidden costs that may affect your procurement decision. Without transparency regarding these factors, the decision to invest in high-performance padel rackets can become risky.

- Material Selection: Different raw materials such as glass fiber, 3k, 12k, and 18k carbon fiber offer distinct properties. Differences in durability, performance, and price can significantly affect the final cost.

- Labor and Production Costs: A streamlined production process versus a manual-intensive process can create cost discrepancies even when manufacturing similar products.

- Customization Fees4: Options like custom shapes (Diamond, Round, Teardrop), logo printing, specialized hand grip, and handle cover customizations tend to add extra costs.

- Supply Chain Efficiency5: Efficient logistics and timely delivery impact the overall cost effectiveness, especially when dealing with international suppliers.

Before evaluating different suppliers, it is essential to unpack the reasons behind the variations in cost. The production process of custom padel rackets involves several steps each contributing to the overall expense. Here’s a breakdown of some primary contributors:

-

Raw Material Selection:

The choice of material, whether it is glass fiber or various grades of carbon fiber, greatly influences the base cost. Higher-grade materials typically deliver better performance and durability but come at a premium cost. -

Labor Intensive Processes:

Advanced production techniques ensure precision and durability, especially for high-performance sports equipment. Experienced labor and state-of-the-art machinery are fundamental, and any inefficiencies or delays can escalate cost. -

Customization Options:

Custom features such as bespoke shapes, bespoke printing, and additional logo placements require specialized setups that add to both labor and production overheads. For businesses aiming to include brand-specific details, these costs are inevitable. -

Supply Chain and Logistics:

Timely sourcing of materials and quick turnaround in production are hallmarks of companies like NEX Padel. Effective synchronization across the supply chain minimizes delays and excess inventory, offering cost advantages that can be passed on to the buyer.

The most effective way to compare suppliers is through a detailed table that outlines each cost component. The table below provides a generalized cost structure for custom padel rackets. Note that the percentages represent a proportionate impact on the final penalty price rather than the absolute cost.

| Cost Component | Estimated Impact (%) | Description |

|---|---|---|

| Raw Materials | 40% | The selection between glass fiber and different grades of carbon fiber (3k, 12k, 18k) can significantly swing costs. |

| Labor Costs | 25% | Includes skilled labor, machine operation, and quality control. |

| Customization Fees | 20% | Custom shapes, logo printing, hand grip, and handle cover personalization. |

| Supply Chain & Logistics | 10% | Efficiency in material sourcing, transportation, and timely delivery. |

| Overhead Expenses | 5% | Factory overheads and ancillary costs. |

This table allows you to benchmark each supplier’s pricing structure. For instance, if a supplier charges a premium on raw materials but cuts costs on labor by using a more automated process, you might consider balancing these aspects based on your product standards and long-term cost expectations.

To further support your strategic decision-making process, consider the following optimization practices:

-

Materials Quality Verification:

Always request detailed material specifications. Look for certifications and performance data that validate the quality of carbon fiber2 or glass fiber used. Higher quality materials enhance long-term durability, making them a worthy investment despite higher upfront costs. -

Assess Specialization and Customization Capabilities:

Confirm the supplier’s experience with various racket designs (Diamond, Round, Teardrop) and their capacity for full customization. It is essential to evaluate the additional fee structure and turnaround times for customized components. -

Understand Production Techniques:

An in-depth look into the manufacturing process can reveal process efficiencies and quality controls. A supplier employing advanced production techniques reduces the potential for product defects and ensures consistency, which enhances overall product performance. -

Evaluate Supply Chain Efficiency:

Regularly assess how a supplier handles its supply chain operations. An efficient procurement process, just-in-time inventory management, and reliable delivery schedules contribute to cost savings that can be critical for competitive pricing. -

Leverage Data for Negotiation:

Use the detailed cost breakdown data to negotiate better terms. When you understand which cost areas are flexible and which are fixed, you can form a more strategic procurement agreement that benefits both parties. -

Consistency in Quality Audits:

Continuous monitoring and quality audits are crucial. Ensure suppliers have a robust quality assurance process in place. Regular audits and performance reviews help in maintaining consistent quality which, in turn, lowers the risk of returns and additional costs.

Consider the case of a prominent padel equipment distributor that partnered with NEX Padel. The distributor was faced with challenges in balancing the cost structure while maintaining high-quality standards required by well-known brands like Hirostar, Reebok, and Starvie. By conducting a thorough production cost analysis and leveraging detailed component breakdowns, the distributor was able to pinpoint specific cost-saving areas:

- Optimized Material Selection: The distributor shifted some production to incorporate a mix of 3k and 12k carbon fibers to achieve a balance between premium performance and cost efficiency.

- Streamlined Customization Process: By standardizing certain design elements and bulk ordering custom prints, they reduced customization fees significantly.

- Enhanced Supply Chain Coordination: Through closer communication with suppliers and improved logistics, the overall turnaround time and associated costs were minimized.

This example underscores how a data-driven approach in analyzing production costs can lead to actionable strategies that enhance competitive positioning and profitability.

While the above practices and breakdown provide significant insight, there are also limitations to consider:

- Price Fluctuations: Market volatility can affect raw material prices unexpectedly, thus impacting the overall cost structure.

- Regional Variations: Costs can vary based on the location of the manufacturing facility and local labor rates.

- Customization Complexity: While standard designs tend to be more cost-effective, fully customized orders often have hidden complexities which might not be immediately evident.

Understanding these limitations is as essential as knowing the cost structure itself. It empowers you to ask the right questions and seek detailed cost justifications from suppliers during negotiations.

In summary, successful procurement of custom padel rackets hinges on a detailed understanding of the production cost structure. By analyzing cost components including material costs, labor, customization fees, and supply chain efficiency, you are better placed to make informed decisions.

Key takeaways for procurement managers include:

- Conducting a detailed selection process based on a verified cost breakdown.

- Asking for transparent documentation regarding material quality and production methods.

- Negotiating effectively using data-driven insights to balance cost and quality.

- Implementing regular audits and performance reviews to ensure consistency in quality.

We encourage you to utilize these insights as a guide in your supplier evaluations and to reach out for further discussion or consultation on optimizing your procurement strategy. With a clear understanding of these cost factors, you can confidently select the supplier that best fits your business requirements and quality standards.

-

What are the main cost factors in producing custom padel rackets?

The key cost factors include raw material selection, labor expenses, customization fees, and supply chain and logistics efficiency. Each element plays a crucial role in determining the overall pricing and must be evaluated carefully. -

How does material quality impact the pricing of padel rackets?

Higher-quality materials, such as premium grades of carbon fiber, offer superior performance and durability but come with a higher price tag. The balance between cost and performance is essential when selecting material options. -

What should procurement managers look for when comparing suppliers?

They should request detailed breakdowns of production costs, including specific data on labor, materials, and customization fees, as well as review the manufacturer’s quality control processes and supply chain efficiency.

-

advanced production techniques: Reading the article will help you understand how modern production methods increase efficiency, improve product quality, and reduce costs. ↩

-

carbon fiber: Discover the properties and performance benefits of carbon fiber, including its strength, weight advantages, and cost implications in sports equipment manufacturing. ↩ ↩2

-

glass fiber: Learn about the role of glass fiber in production, its cost-effectiveness, and how it compares with other composite materials in terms of durability and performance. ↩

-

Customization Fees: Read further to understand how customization options impact pricing, what factors contribute to these costs, and strategies to manage and negotiate them. ↩

-

Supply Chain Efficiency: Explore how streamlined logistics, coordinated inventory management, and effective supplier relationships can reduce lead times and overall costs. ↩