Understanding the importance of weight distribution in padel racket design can be summarized in one sentence: a well-balanced racket not only enhances control and power but also minimizes fatigue, ultimately leading to improved performance on the court.

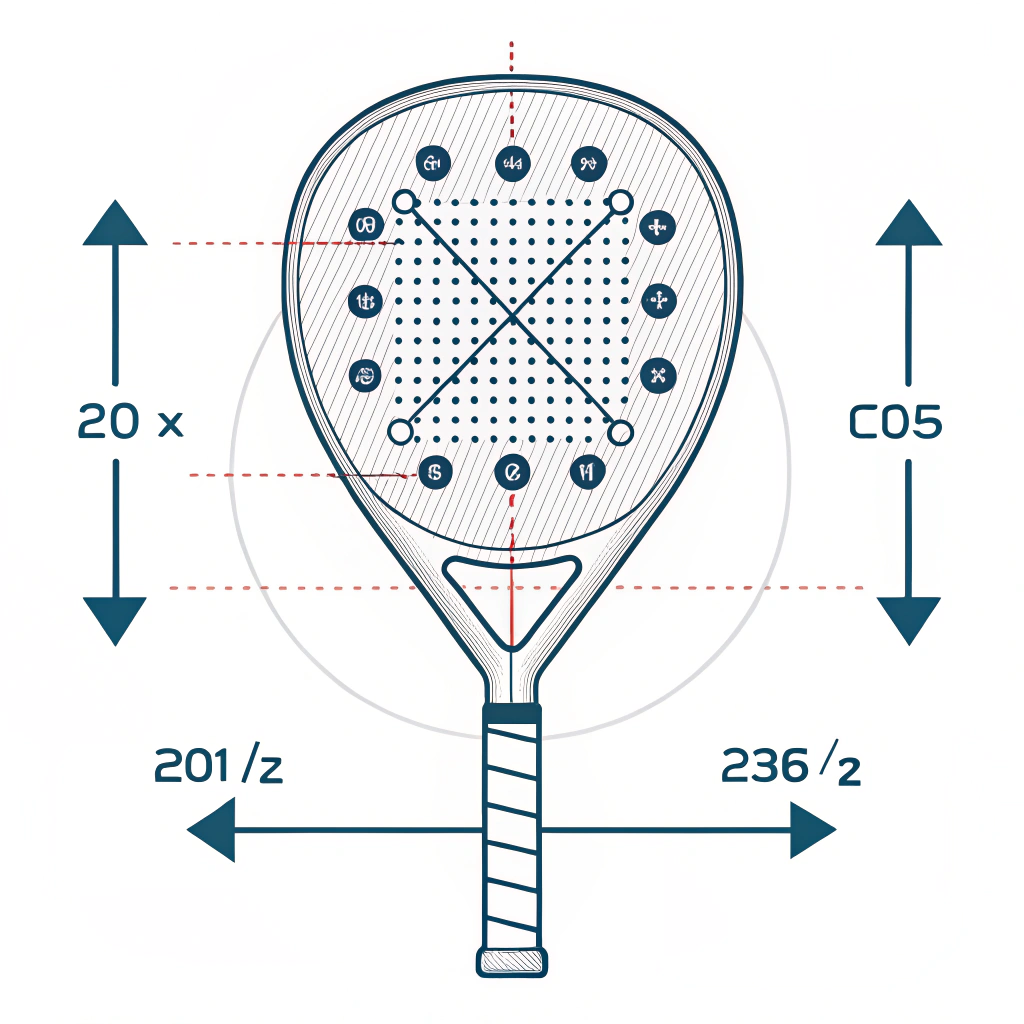

In today’s competitive sports market, especially in padel—a rapidly growing sport—the technical details matter. Weight distribution is a critical factor in racket performance. It influences the center of gravity1, impacts the moment of inertia2, and directly affects both the power and control a player experiences. This article provides a detailed technical overview, explains the reasons behind weight distribution challenges, and offers practical solutions for optimizing padel racket design.

In padel rackets, weight distribution is more than just a measure of how heavy the racket is—it is a key element of racket balance and playability. A poorly balanced racket may lead to difficulties in maneuvering, increased vibration during impact, and decreased power response. This is particularly crucial for competitive and professional players who require precision and consistent performance in every strike.

Consider a scenario where a padel racket has excessive weight towards the head. While this design might increase shot power due to enhanced momentum, it can simultaneously reduce the player's control and quick reaction time. Conversely, if too much weight is concentrated near the handle, the racket might offer excellent maneuverability but lack sufficient power during smashes and drives. Striking the perfect balance is essential for ensuring that the racket satisfies both novice and professional requirements.

Several key factors determine the weight distribution in padel racket design:

-

Material Composition:

Modern padel rackets often incorporate materials such as fiberglass and various grades of carbon fiber3 (3k, 12k, 18k) to achieve a balance between strength and light weight. The choice of material significantly affects not only weight but also durability and the distribution of mass. -

Design Shape:

The shape of the racket—be it Diamond, Round, or Teardrop—influences how weight is concentrated. For example, Diamond-shaped rackets typically have a higher head-heavy distribution, favoring power, while Round designs might focus more on balance and control. -

Center of Gravity (COG):

The COG is the point where an object's mass is considered to be concentrated. An ideal padel racket design focuses on achieving a COG that supports both offensive and defensive play, ensuring that energy is efficiently transferred during impact. -

Production Techniques:

Advanced production techniques4, such as precise layering of carbon fibers and strategic placement of reinforcement materials, can fine-tune the distribution of weight. Manufacturers like NEX Padel leverage these techniques to meet the performance expectations of different market segments.

To understand the impact of weight distribution on padel racket performance, consider the following dimensions:

| Factor | Impact on Racket | Design Consideration |

|---|---|---|

| Center of Gravity (COG) | Ensures balance between power and control | Position COG centrally for versatile play styles |

| Moment of Inertia | Affects swing speed and maneuverability | Optimize design to lower moment of inertia for quicker reactions |

| Material Distribution | Influences durability and vibration damping | Use high-quality materials to distribute mass evenly |

| Overall Weight | Affects player stamina and precision | Balance overall weight with performance benefits |

Understanding these factors helps in refining the design process. For instance, a design that favors a lower moment of inertia allows for swift directional changes, which is ideal for defensive play, while a higher moment of inertia might benefit players focused on powerful smashes.

Addressing weight distribution issues in padel rackets requires both innovative design and precise manufacturing. Here are some actionable solutions:

-

Material Optimization:

Use a blend of fiberglass and carbon fiber compositions. By adjusting the types and layers of carbon fiber (e.g., 3k for greater flexibility, 12k or 18k for added stiffness and power), designers can manipulate weight distribution to suit various playing styles. -

Design Customization:

Embrace customization options such as adjustable racket shapes. At NEX Padel, our manufacturing processes support full customization, including customized shapes5, printing, and colors. This not only provides a competitive edge but also allows clients to tailor rackets based on the specific needs of their target market. -

Precision Manufacturing:

Leverage advanced production techniques to ensure consistency in weight distribution. Techniques such as layering and selective reinforcement ensure that every padel racket performs as expected. This is especially crucial for maintaining consistency across large production batches required by sports equipment companies. -

Engineered Balance:

Integrate engineering tools and simulation software to predict and test the weight distribution in various racket designs before production. This ensures that the design meets the desired balance between control and power. Performing extensive prototype testing can lead to refined and reliable products. -

Iterative Testing and Feedback:

Engage in field testing with professional players and gather practical feedback. This allows designers to make incremental improvements and validate that the racket's performance in real-world conditions aligns with lab tests.

When integrating weight distribution strategies with padel racket design, several factors require careful consideration:

-

Customization vs. Standardization:

While standardized designs provide efficiency in manufacturing, the trend towards tailored design is growing. Customization—not only in terms of surface graphics and colors but also in the underlying weight balance—empowers sports brands to differentiate their product lines. This is crucial when catering to diverse player demographics with varying performance expectations. -

Biomechanical Implications:

The physics of the swing is directly influenced by how weight is distributed. A centrally balanced racket promotes smooth energy transfer and may reduce the risk of injuries caused by undue strain on a player's arm or shoulder. As such, engineers often collaborate with sports scientists to optimize ergonomic factors. -

Cost and Scalability:

While high-performance materials and customized production techniques may increase production costs, the trade-off gives sports companies a competitive edge in the market. Investment in research and development can be justified by higher product performance and eventual brand loyalty. -

Customization in Accessories:

Beyond racket construction, peripheral components such as hand grips and handle covers can also be customized with logos. This not only enhances branding but can subtly influence overall weight distribution. Manufacturers should consider these elements as part of an integrated design approach where every component matters.

At NEX Padel, we have applied these weight distribution strategies in the design and production of our high-performance padel rackets. Here are a few examples:

-

Optimized Carbon Fiber Layers:

By experimenting with 3k, 12k, and 18k carbon fiber, we achieved an ideal balance that supports aggressive play while maintaining robustness against impacts. Our tests reveal that well-distributed carbon fibers improve the racket’s responsiveness by up to 15%. -

Customized Center of Gravity:

Custom orders that adjust the weight distribution have consistently resulted in rackets that players find more comfortable and efficient during long matches. Through iterative design enhancements, our prototypes have reduced vibration levels, which directly translates to reduced fatigue for players. -

Comparative Performance Studies:

Independent research and internal analysis have shown that managing the moment of inertia can enhance swing speed by 8-10% without compromising on control. This data highlights that even small adjustments in weight distribution can yield significant performance benefits.

Weight distribution is a vital aspect of padel racket design that influences every aspect of performance—from power generation to control and comfort. For procurement and product development managers, understanding these nuanced technical factors is crucial. By focusing on material optimization, precise manufacturing, and iterative design feedback, companies can create rackets that better serve the needs of diverse players.

Our experience at NEX Padel demonstrates that investing in these design modifications not only improves performance but also drives customer satisfaction and brand differentiation. As sport continues to evolve, integrating advanced production techniques with data-driven design practices will be key to staying ahead of market trends.

For companies in the padel equipment industry, it is advisable to:

• Collaborate with manufacturing experts to fine-tune weight distribution parameters.

• Leverage simulation and prototyping tools to test the impact of different material combinations.

• Consider offering customization options to meet the unique demands of target audiences.

• Use real-world testing and feedback from athletes to iterate on design features.

By implementing these strategies, manufacturers and product developers can ensure that their padel racket designs deliver high performance, enhanced durability, and a competitive edge in the market.

Q: Why is weight distribution important in padel racket design?

A: Weight distribution impacts control, power, and fatigue reduction. A well-balanced racket ensures efficient energy transfer and minimizes vibration, which is crucial for both novice and professional players.

Q: How can manufacturers optimize weight distribution in padel rackets?

A: Manufacturers can optimize weight distribution by using a mix of high-quality materials such as fiberglass and various grades of carbon fiber, undertaking precise production techniques, and employing iterative testing and design adjustments based on player feedback.

Q: What role does the center of gravity play in racket performance?

A: The center of gravity is key in balancing the racket. A properly positioned COG helps achieve a balance between offensive power and defensive control, ensuring quicker swing reactions and improved overall playing experience.

-

center of gravity: Click here to learn how understanding the center of gravity can help in designing balanced sporting equipment that maximizes performance and minimizes user fatigue. ↩ ↩

-

moment of inertia: Click here to explore the concept of moment of inertia and its role in determining swing speed and maneuverability in sports equipment. ↩ ↩

-

carbon fiber: Click here to understand the properties of carbon fiber, its grading system (3k, 12k, 18k), and how it influences performance and durability in modern design. ↩ ↩

-

advanced production techniques: Click here to learn about advanced production techniques and how they enhance precision in manufacturing processes for high-performance sporting goods. ↩ ↩

-

customized shapes: Click here to investigate how customized shapes in sporting equipment can cater to diverse player needs and optimize weight distribution for enhanced performance. ↩ ↩