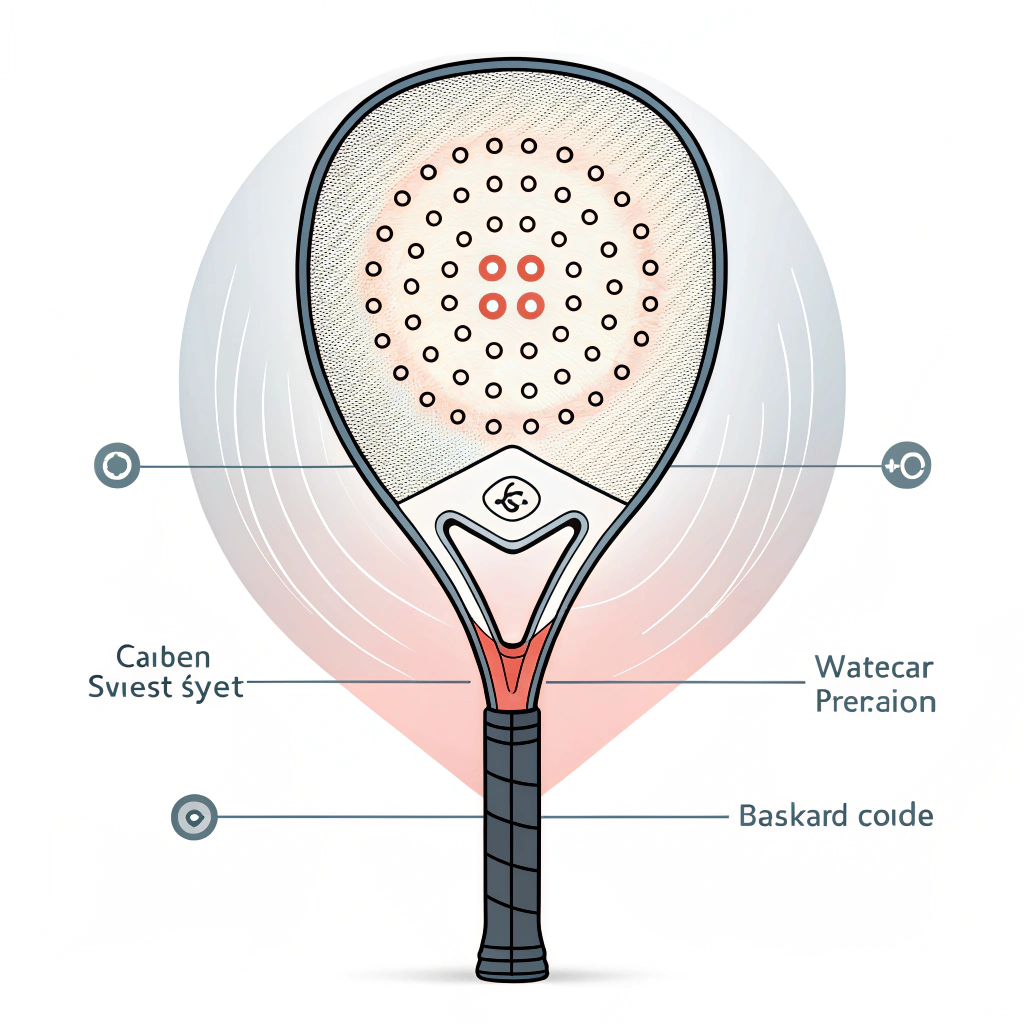

The sweet spot in a padel racket is the optimal impact zone where players achieve the best power, precision, and comfortable response. This ideal area minimizes vibration and maximizes energy transfer to the ball, contributing significantly to overall game performance.

In today’s competitive padel landscape, understanding the sweet spot1 is vital for technical product managers and buyers. The sweet spot is not only essential for delivering player satisfaction but also a prime focus in the design and manufacturing of high-performance rackets. When produced with advanced materials like carbon fiber2 (available in 3k, 12k, and 18k weaves), the sweet spot becomes a critical attribute to enhance your product portfolio.

The sweet spot of a padel racket is the area on the racket face where a ball strike results in the most efficient transfer of momentum. Essentially, this is the zone where the maximum energy from the racket is imparted to the ball, leading to greater shot precision and power. When hits occur outside the sweet spot, vibrations increase and power is lost, making it harder for players to control the ball.

- Enhanced Power and Precision: A well-defined sweet spot maximizes the energy transfer. This is crucial during intense rallies and high-level matches.

- Reduced Vibration: By centralizing the impact zone, racket designs can minimize vibration, reducing the risk of arm injuries and improving overall comfort.

- Optimized Player Performance: Consistency in shot-making is improved with a larger and well-placed sweet spot, allowing players to feel confident and in control.

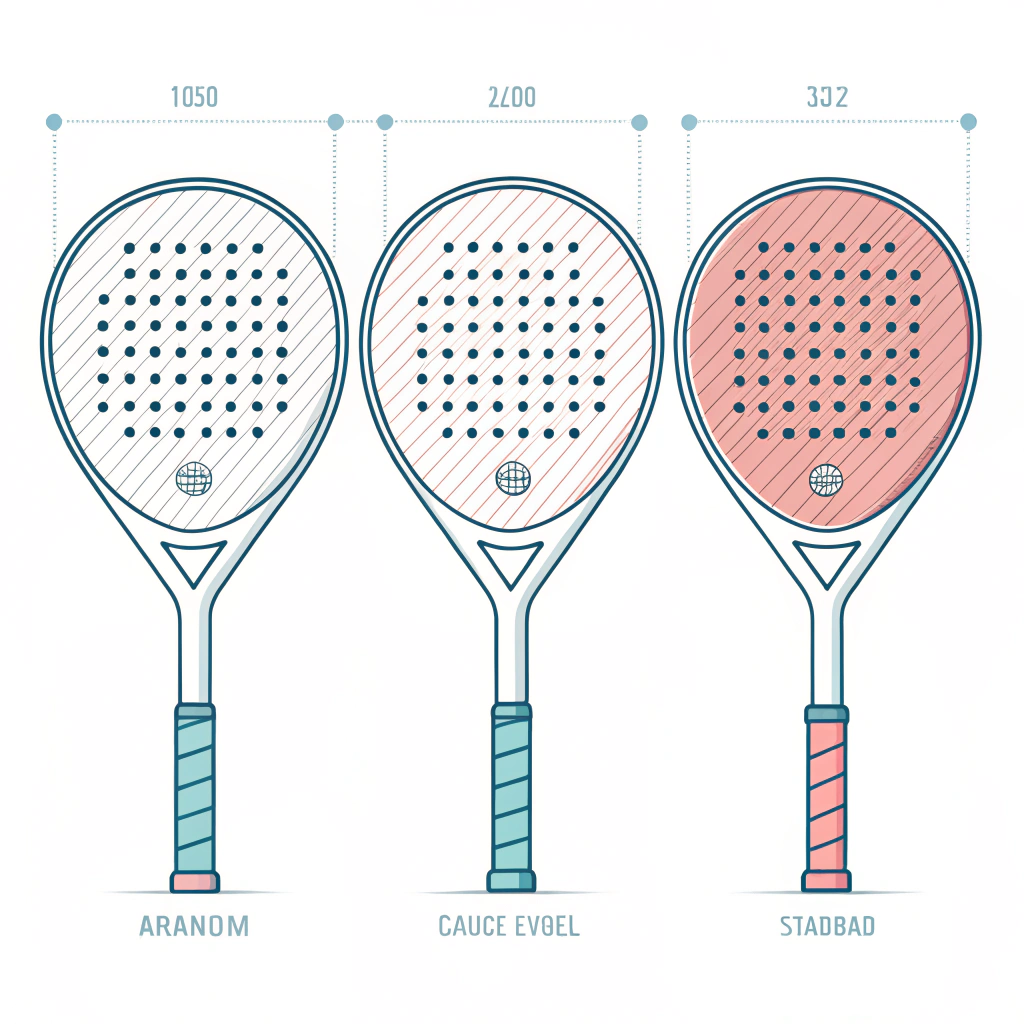

Padel rackets come in various shapes—Diamond, Round, and Teardrop—each influencing the racket balance and the effective area of the sweet spot. A well-engineered design ensures that the sweet spot aligns with the racket’s center of gravity for maximum performance.

| Racket Shape | Center of Gravity | Sweet Spot Characteristics | Ideal For |

|---|---|---|---|

| Diamond | Lower center | Slightly smaller but with increased power output due to a forward balance | Aggressive play, players seeking high power |

| Round | Center-weighted | Larger sweet spot offering better control and comfort | All-around play, beginners to intermediate players |

| Teardrop | Balanced shift | Optimized for a blend of power and control with moderate sweet spot size | Versatile play, mixed style players |

Every design involves a trade-off between power and control, and the manufacturing process plays a decisive role in ensuring that the sweet spot is maximized. By using precision manufacturing and advanced composite materials, companies like NEX Padel innovate in shaping the sweet spot to match diverse playing styles and market demands.

To optimize the sweet spot, several key factors must be considered during the design and manufacturing process:

1. Precision Manufacturing3 and Material Selection

- Advanced Carbon Fiber Technology: Using high-performance carbon fibers (3k, 12k, 18k) allows engineers to design rackets with superior stiffness. This enhances the stability of the sweet spot and minimizes energy loss during off-center hits.

- Composite Layering4: Incorporating layers of glass fiber with carbon fiber can offer a combination of durability and vibration damping. This ensures that the response at the sweet spot is maintained over time.

- Customized Balance Adjustment: Fine-tuning the center of gravity ensures the sweet spot is positioned accurately. Whether the racket is Diamond, Round, or Teardrop, the balance impacts both power distribution and vibration reduction.

2. Design for Vibration damping5

Vibration damping is key to reducing the uncomfortable shock felt by players on off-center hits. Incorporating specific damping materials and design features helps in absorbing excess energy, meaning that even if the ball is not perfectly centered on the sweet spot, the negative effects are mitigated. This technological advancement is particularly important for high-performance and competitive padel play.

The design process now includes:

- Simulation testing: Advanced simulation techniques help predict the racket performance under different conditions. This includes modeling how the energy is transferred at various points on the racket face.

- Field trials: Feedback from professional players and clubs is integrated into iterative design improvements. This ensures that the final product not only meets theoretical benchmarks but also real-world playing conditions.

| Aspect | Best Practices | Impact on Performance |

|---|---|---|

| Sweet Spot Positioning | Align with the center of gravity | Maximizes energy transfer |

| Material Composition | Use high-quality carbon fiber and strategic composite layering | Enhances stiffness and vibration damping |

| Vibration Control | Include integrated damping systems in key areas | Reduces player fatigue and risk of injury |

| Design Customization | Offer options for customized shapes, prints, and hand grips | Meets diverse playing preferences |

| Prototyping and Validation | Use simulation and on-field testing, adjusting as needed | Ensures consistency and reliability |

These guidelines help ensure that the sweet spot not only exists in theory but performs effectively during match play.

For distributors and club operators, understanding and selecting a padel racket with an optimized sweet spot is a strategic decision. At NEX Padel, we cater to premium brands like Hirostar, Reebok, and Starvie by providing rackets that exhibit excellence in both design and manufacturing precision.

- Player Satisfaction and Performance: A racket with a large, well-engineered sweet spot offers better performance. This leads to higher player satisfaction and a better reputation for your brand or club.

- Competitive Advantage: Offering a product that integrates advanced sweet spot technology can be a unique selling proposition in a crowded market.

- Customization Flexibility: The option for customization—be it shape, color, or even logo details on the hand grip or handle cover—ensures that each racket can be tailored to meet distinct market or club needs. This flexibility is particularly valuable when aiming to meet the demands of professional play.

Below is a simplified feature matrix that helps align product features with performance and buyer needs:

| Feature | Importance | Recommendation |

|---|---|---|

| Sweet Spot Size | Key factor for shot consistency | Look for rackets with precise energy transfer |

| Center of Gravity | Affects balance and control | Ensure customization offers optimal weight distribution |

| Vibration Damping | Critical for player comfort | Select designs that integrate advanced damping materials |

| Material Quality | Durability and performance | Prioritize rackets built with high-grade carbon and composite fibers |

| Customization Options | Variety and brand differentiation | Opt for suppliers like NEX Padel with full customization ability, including hand grips and handle covers |

This comprehensive approach aids buyers in understanding the technical nuances while matching them with specific gameplay needs.

Additional techniques can further extend the benefits of a well-engineered sweet spot:

- Dynamic Balance Adjustments: Manufacturers use real-time testing to adjust the weight distribution and ensure the sweet spot remains consistent across different playing conditions.

- Iterative Prototyping Using Player Data: By reviewing player feedback and incorporating data analytics, design iterations continuously refine the sweet spot's effectiveness.

- Multi-Layer Composite Strategies: In-depth research supports the development of multi-layered composites that combine rigidity with flexibility, targeting both performance and longevity.

Such innovations not only enhance the playing experience but also provide a robust competitive edge in the padel equipment market. With advanced simulation tools and precise manufacturing practices, suppliers can fine-tune every element of the racket, from the sweet spot to the overall aesthetics, ensuring that players receive premium quality products that support high-level performance.

To sum up, the sweet spot on a padel racket is a significant indicator of performance. It represents the intersection of advanced materials, precise manufacturing, and optimal design philosophies. A well-optimized sweet spot ensures maximal energy transfer, reduced vibrations, and enhanced playability, thereby meeting the stringent demands of high-level padel play.

For technical product managers and buyers, understanding this concept is crucial when evaluating supplier capabilities and product quality. NEX Padel’s commitment to precision manufacturing, customization, and advanced design techniques ensures that our products can meet the sophisticated needs of both professional and recreational players alike.

By integrating the guidelines and best practices discussed, you can make more informed decisions that enhance player satisfaction and drive your brand’s competitive edge. If you are looking to source high-performance padel equipment with optimal sweet spot properties, consider reaching out for detailed technical specifications and customization options that align with your market strategy.

People Also Ask

Q: What is the sweet spot in a paddle?

A: The sweet spot is the area on the paddle face where contact with the ball delivers maximum energy transfer, resulting in the truest response, high power, and accuracy.

Q: What is sweet spot in racket?

A: It is the specific zone on the racket where the maximum forward momentum is absorbed and efficiently transferred to the ball, ensuring a greater velocity with minimal vibration or twist.

Q: What is the sweet spot on a racquet?

A: The sweet spot refers to the longer, more comfortable area on the string bed where optimal power and control are achieved, making off-center hits less detrimental to performance.

-

sweet spot: Click to learn about the optimal impact zone in padel rackets, including how its precise positioning enhances power, precision, and player comfort. ↩ ↩

-

carbon fiber: Click to read about carbon fiber technology, its variations (3k, 12k, 18k), and the role it plays in improving racket stiffness and performance. ↩ ↩

-

Precision Manufacturing: Click to understand how precision manufacturing techniques ensure consistent quality, optimal balance, and peak performance in padel rackets. ↩ ↩

-

Composite Layering: Click to learn about composite layering strategies that combine different fibers for improved durability, stiffness, and vibration control in racket construction. ↩ ↩

-

Vibration damping: Click to explore methods and technologies used to reduce unwanted vibrations in racket design, thereby enhancing player comfort and reducing injury risk. ↩ ↩