Padel rackets command a higher price tag due to the use of advanced materials1, complex manufacturing processes2, and extensive customization options3 that all contribute to exceptional performance and durability.

In today’s competitive sports equipment market, understanding the cost structure behind premium padel rackets is crucial for purchasing managers and product developers. This guide provides an in-depth look into the factors that make padel rackets more expensive compared to other sports equipment. We will explore advanced materials such as various grades of carbon fiber4, elaborate manufacturing processes, and the importance of customized design options—all of which are essential for delivering the high performance expected by professional players and serious enthusiasts.

One of the most significant drivers of cost in padel rackets is the selection of high-quality materials. Unlike many other sports equipment, padel rackets are designed for rigorous use and need to withstand thousands of impacts throughout their lifetime.

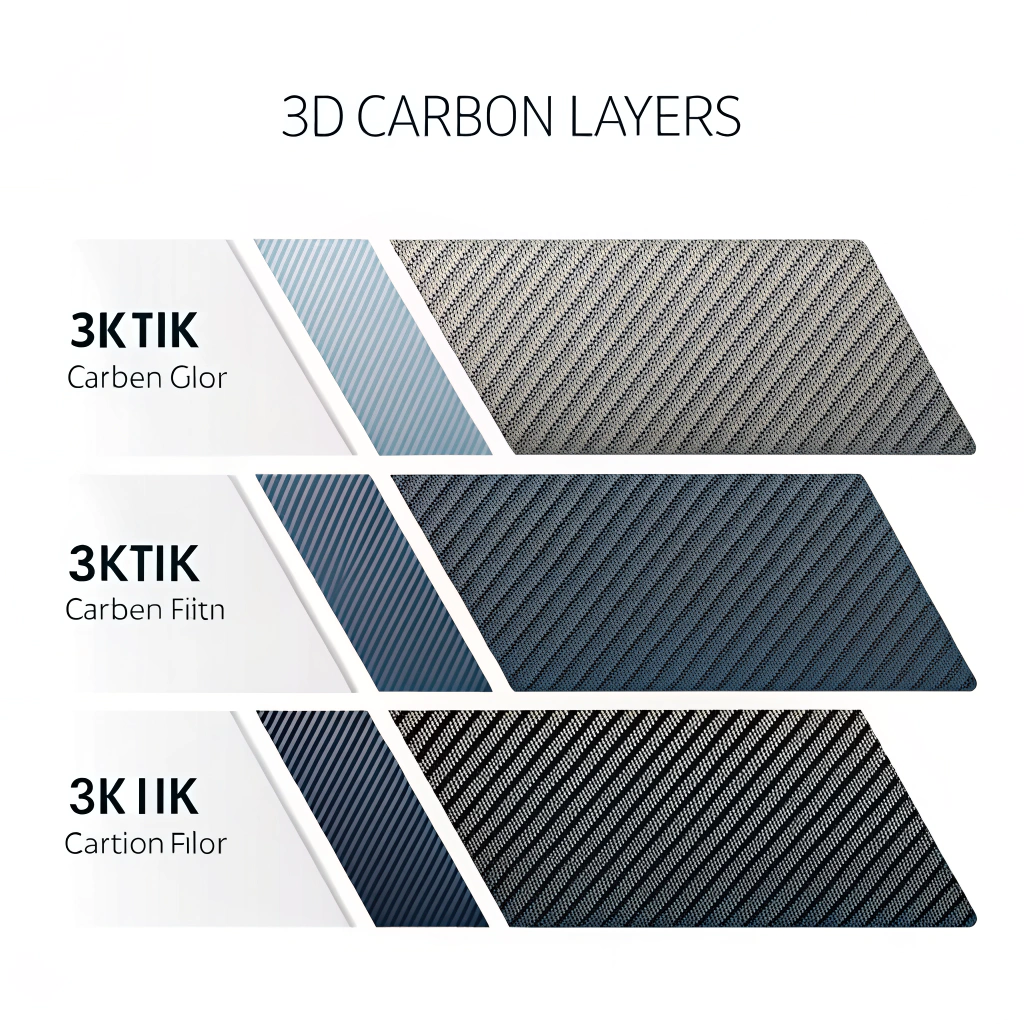

- Carbon Fiber Grades: Premium padel rackets use a range of carbon fiber types from 3k, 12k, to 18k carbon fibers. These materials differ in terms of tensile strength, stiffness, and weight.

- 3k Carbon Fiber: Offers excellent weight reduction and flexibility, ideal for players who prefer maneuverability.

- 12k Carbon Fiber: Provides a balanced mix of strength and responsiveness.

- 18k Carbon Fiber: Delivers maximum rigidity and durability, ensuring that the racket remains stable during high-impact play.

The choice of carbon fiber significantly influences the final cost because higher grades require sophisticated processing and quality control measures. Additionally, each padel racket may combine carbon fiber with other materials such as fiberglass to achieve the best balance between durability and performance.

The manufacturing process of padel rackets is another critical factor that drives up their cost. Unlike tennis rackets—which generally have a simple frame and grip assembly—padel rackets are solid structures that need to absorb and transfer impacts efficiently. This requires a series of advanced production techniques that include:

- Layering & Molding Processes: The construction of a padel racket involves the precise layering of composite materials. Automated production techniques are deployed to ensure consistency, but significant manual oversight is needed to maintain high standards.

- Quality Control5: Each product undergoes rigorous testing to ensure it meets durability and performance benchmarks. This includes stress tests, impact tests, and drag tests, all of which require specialized equipment and expertise.

- Customization Equipment: Offering customized shapes (Diamond, Round, Teardrop) and personalized printing options involves additional equipment and process adaptation. Each order might require adjustments in the production line, leading to increased manufacturing time and expenses.

Customization is a key element in premium padel rackets that sets them apart from mass-produced alternatives. Clients often request personalized color schemes, logos on hand grips and handle covers, and even fully customized racket shapes. This flexibility not only caters to brand differentiation but also to player comfort and aesthetics. The additional design inputs require:

- Design Prototyping: Quick sample production and iterative design modifications to ensure that the final output aligns with client specifications.

- Special Production Runs: Low volume, highly customized production runs often lead to higher unit costs compared to standard molds due to setup costs and the need for bespoke tooling.

Such bespoke services are highly valued among professional sports equipment suppliers, but they naturally come at a premium cost.

The following table summarizes major cost drivers in the production of premium padel rackets, illustrating how each factor adds value and influences the overall price:

| Cost Driver | Explanation | Impact on Cost | Benefits |

|---|---|---|---|

| Advanced Carbon Fibers | Utilization of 3k, 12k, and 18k carbon fibers for different performance metrics | Higher material cost and processing expenses | Enhanced performance, durability, and weight distribution |

| Complex Manufacturing | Multi-layer composite construction, precision molding, and rigorous testing | Increased labor and equipment costs | Consistent quality and long-term durability |

| Customization Options | Custom shapes, printing, and personalized grip designs | Higher setup and production costs | Tailored product design, improved brand differentiation |

| Quality Control Measures | Extensive testing protocols ensuring every racket meets high standards | Increases production time and costs | Reliability and enhanced performance under stress |

| Production Flexibility | Ability to adapt production lines for custom orders | Non-standard production leads to higher costs | Faster prototyping and adaptation to market needs |

At NEX Padel, we have built our reputation on our ability to deliver high-performance padel rackets through a combination of advanced production techniques and premium materials. For instance, our collaboration with well-known brands like Hirostar, Reebok, and Starvie demonstrates our capability to meet diverse and high-standard requirements. Our comprehensive approach includes:

- Rapid Prototyping: We quickly produce samples, which allows for fast implementation of design feedback.

- On-Demand Customization: With technologies in place to adjust shapes and designs, we offer fully customized padel rackets that meet specific market demands.

- Quality Assurance: Our rigorous quality control ensures that every racket, whether it’s the Diamond, Round, or Teardrop type, adheres to strict performance and longevity standards.

The investment in such technologies and processes may result in a higher initial cost; however, it provides end users with equipment that can enhance player performance while ensuring safety and durability under high-impact conditions.

For purchasing managers and product developers, several critical considerations must be understood when evaluating padel racket costs:

- Material Quality vs. Cost Efficiency: While premium materials like 18k carbon fiber deliver superior performance, managers should weigh the benefits against the increased cost. In many cases, a mix of 12k and 3k carbon fibers can achieve a balance between performance and budget.

- Total Cost of Ownership: The higher upfront expenditure on a premium racket often translates into long-term savings. High durability reduces the need for frequent replacements, and advanced design can lead to enhanced performance and lower injury rates over time.

- Customization Needs: A fully customized product may address specific branding or performance needs better than a standard model. Although this incurs additional costs, it can form a key competitive advantage in markets where brand identity and product performance are critical.

A detailed cost analysis should consider both the short-term outlay and the long-term value added by investing in sophisticated manufacturing processes and high-quality materials.

Based on our comprehensive overview, here are clear action points for purchasing managers and product developers considering premium padel rackets:

- Perform a Cost-Benefit Analysis: Examine your requirements and budget constraints. Evaluate if the enhanced performance and durability provided by advanced materials and customization justify the premium pricing for your target market.

- Engage with Manufacturers like NEX Padel: Discuss your customization, material, and performance requirements. Our team can offer bespoke solutions tailored to your market, ensuring that you invest in technology that provides lasting value.

- Emphasize Quality Assurance: When comparing suppliers, carefully review their quality control standards and testing procedures. Reliability is a cornerstone of premium sports equipment, and thorough evaluations help ensure that your final product meets the expected standard.

Investing in high-performance padel rackets is more than just an expense; it is a strategic decision that can enhance your product portfolio and support long-term customer satisfaction.

In summary, the elevated cost of premium padel rackets is driven by the integration of cutting-edge materials, complex manufacturing techniques, and extensive customization options. For purchasing managers and product developers, understanding these factors is essential for making informed decisions. While the initial investment may be higher, the long-term benefits—such as enhanced performance, durability, and brand differentiation—offer compelling reasons to choose high-quality padel equipment.

As you explore options for upgrading your sports equipment portfolio, carefully consider how each factor contributes to the value of a padel racket. Our experience at NEX Padel, backed by advanced production capabilities and robust quality control, ensures that you receive a product that meets the rigorous demands of professional play. We invite you to further investigate our comprehensive solutions backed by data-driven insights, ready to support your strategies in delivering premium sports equipment.

People Also Ask

Q: Why are some padel rackets so expensive?

A: Padel rackets are more expensive because their production involves complex processes and advanced materials, such as various grades of carbon fiber, that ensure high durability and performance. Their solid construction is designed to withstand repeated impacts, necessitating precision manufacturing and rigorous quality control.

Q: How much should I spend on a padel racket?

A: The cost of a padel racket largely depends on the materials used and the level of customization. Advanced players are often advised to invest from around £170, though many choose to spend more—up to £400 or beyond—to access features that enhance comfort, durability, and overall performance.

-

advanced materials: Click to learn how innovative materials drive enhanced performance and durability in sports equipment. ↩

-

complex manufacturing processes: Click to explore the sophisticated production techniques that ensure consistent quality and precision in advanced sports equipment. ↩

-

extensive customization options: Click to discover how tailored design features create competitive differentiation and meet specific market demands. ↩

-

carbon fiber: Click to gain insights into the various grades of carbon fiber and their impact on structural performance and weight optimization. ↩

-

Quality Control: Click to learn about rigorous testing and quality assurance practices that ensure product reliability and peak performance. ↩