Quick Answer: This guide provides a step-by-step overview of what to expect when placing your first OEM padel rackets1 order—from understanding the production process and customization options2 to managing production lead times3, quality control4, and cost factors. It is designed to help procurement managers and product development specialists make an informed decision when selecting an OEM padel manufacturing partner.

When you decide to order OEM padel rackets, the process can seem daunting, especially if it’s your first time venturing into the ordering process. For many sporting goods companies, ensuring that production quality, lead times, and customization options meet their expectations is crucial. This comprehensive guide addresses these challenges by breaking down the production stages, explaining the available customization options, and offering actionable advice based on real-world manufacturing insights.

OEM padel racket manufacturing involves multiple critical factors, including material selection, production techniques, quality control, and branding customization. At NEX Padel, based in Jiaxing, Zhejiang, China, we understand the importance of these elements. Our advanced production techniques5 and flexible design capabilities—from standard shapes like Diamond, Round, and Teardrop to fully custom designs with personalized logos—are geared toward delivering a product that meets both performance and aesthetic standards.

For many procurement managers, the initial hurdle is understanding the entire OEM ordering process. They are often concerned with the following aspects:

- How detailed customization works, and what production materials are available (e.g., advanced carbon fiber varieties such as 3K, 12K, or 18K).

- How production lead times3 can affect market timelines and revenue.

- The quality control4 measures within the padel manufacturing process.

- How to navigate the balance between cost, performance, and durability.

Every new OEM ordering experience carries inherent risks—miscommunications about design specifications, unexpected production delays, or compromises in quality. For companies eager to innovate in the padel market, partnering with a manufacturer that offers full-service customization and robust quality control can be a game changer.

The challenges outlined above typically stem from several factors:

-

Complex Customization Requirements: Modern padel rackets often incorporate multiple design elements including special shape molds, unique color schemes, and branded logos. Lack of clarity in these specifications can lead to production errors.

-

Stringent Quality Control Needs: As padel rackets are high-performance sporting equipment, they require precise manufacturing techniques. Variability in materials or production processes can significantly affect performance and durability.

-

Fluctuating Production Lead Times: Balancing speed and quality can be difficult. While quick turnarounds are appealing, compromising on the production process may lead to lower quality products.

-

Cost Considerations: Pricing in OEM padel manufacturing can be sensitive to factors like material cost, production volume, and customization complexity. A clear understanding of these cost drivers is vital for effective budget management.

In this section, we present actionable steps to help you navigate the OEM padel racket ordering process successfully. This solution-oriented approach is designed for procurement managers and product development specialists seeking to minimize risk while maximizing customization and quality outcomes.

The first step in any OEM process is developing a detailed list of specifications:

- Design Specifications: Determine whether you prefer a Diamond, Round, or Teardrop design. Consider if you need a custom shape that aligns with your branding.

- Material Selection: Choose from high-quality materials available, such as glass fiber or carbon fiber options (3K, 12K, or 18K). Each material offers a different balance of flexibility and strength.

- Branding and Customization: Decide on custom logo placements, court colors, and even details like the hand grip or handle cover.

- Performance Metrics: Consider factors such as balance, weight, and overall racket performance, ensuring the product meets the intended player experience and durability requirements.

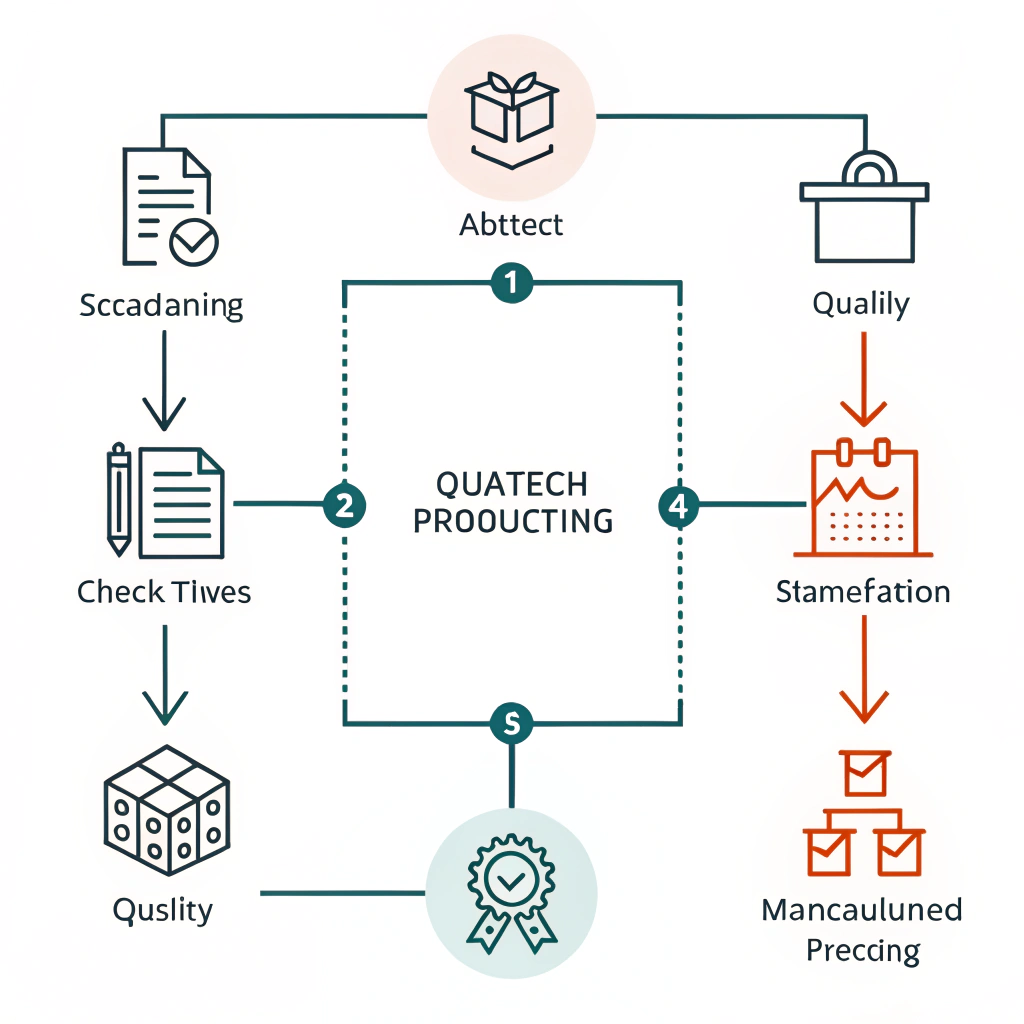

A thorough understanding of the manufacturing journey helps in managing expectations and planning timelines effectively. The production process typically includes:

- Design Confirmation: After detailing the specifications, the design team creates prototypes and prototypes for approval.

- Material Selection & Sourcing: Depending on your chosen configuration, appropriate materials are sourced.

- Manufacturing Process: Advanced production techniques, such as precision molding, layering of carbon fibers, and finishing touches like custom printing on handle grips or racket frames, are employed.

- Quality Assurance: Strict quality control measures are implemented at every stage, ensuring that each padel racket meets international standards.

- Packaging & Delivery: Final products are packaged securely (e.g., using pressurized tube packaging for padel balls) and delivered within the specified lead time.

A clear diagram of the process can often be very helpful. The following table outlines a typical timeline and key production stages:

| Stage | Timeframe (Days) | Key Activities | Customization Options |

|---|---|---|---|

| Design and Specification | 5 - 10 | Requirements, prototype development | Shape, color scheme, logo placement |

| Material Sourcing | 3 - 5 | Selection of glass fiber and carbon fiber types | Material grades (3K, 12K, 18K) |

| Production Setup | 2 - 3 | Tooling and mold preparation | Custom molds for unique designs |

| Manufacturing | 7 - 14 | Molding, layering, finishing | Custom finishes, branding details |

| Quality Checks | 2 - 3 | Inspection, testing, and compliance assurance | Performance testing, durability testing |

| Packaging & Shipping | 2 - 5 | Secure packaging and logistical planning | Custom packaging designs |

This table serves as a guide and may vary depending on order volume and specific product customization.

Quality control is paramount when working with high-performance sporting equipment. At NEX Padel, we implement rigorous quality checks at every stage of production:

- Material Verification: Each material batch is tested for consistency. Our production facility meticulously examines every ingredient—from lower-cost glass fiber to top-grade carbon fibers—to ensure the final product meets durability and performance criteria.

- Process Monitoring: Advanced production techniques such as custom molding and automated layering processes are monitored using precision instruments. This reduces the risk of human error and maintains the integrity of every padel racket.

- Final Inspection: Before leaving the factory, every racket undergoes thorough testing. This includes balance checks, weight calibration, and structural integrity assessments, ensuring that the product lives up to the high standards expected by professional athletes and recreational players alike.

- Feedback Loop: Post-delivery feedback is crucial. We invite our OEM customers to participate in a review process so that insights can be integrated into future production cycles.

Understanding your production timeline and cost contributions is crucial for successful OEM partnerships. Consider these factors:

- Volume vs. Lead Time: Larger orders may benefit from production economies but might require longer lead times. It is important to communicate your scheduling needs early in the process.

- Material and Process Costs: Higher performance materials like 12K or 18K carbon fiber may incur greater costs. However, investing in better materials often leads to improved product longevity and customer satisfaction.

- Customization Complexity: More extensive customization (custom shapes, branding on multiple components like hand grips and handle covers) can extend production time and increase unit cost. Balancing customization and cost is key.

Proactively planning for these variables helps in setting realistic delivery expectations and maintaining a smooth procurement process.

Even with a well-planned process, unexpected issues can arise. Here are some common challenges and suggested mitigation strategies:

- Communication Gaps: Ensure that all product specifications are clearly documented. Regular communication with the manufacturing team is critical. Use digital project management tools to track progress.

- Unforeseen Delays: Build buffer times into your production schedule to account for potential delays, especially during peak production periods.

- Quality Inconsistencies: Regularly review sample outputs and request adjusted prototypes if necessary. Establish clear quality benchmarks and request documentation on quality checks performed.

Implementing these practices minimizes risks and builds a more resilient supply chain.

To illustrate these principles in practice, let’s consider a real-world scenario where a leading sporting goods brand partnered with NEX Padel for a custom line of padel rackets. The company was determined to introduce a new model that balanced performance with an innovative design. Here’s how the process unfolded:

-

Requirement Definition: The brand provided detailed design specifications, including a preferred round shape for better control and a custom color palette to align with its brand identity. They also specified the use of 12K carbon fiber for enhanced durability without adding excessive weight.

-

Prototype and Feedback: Our design team rapidly developed prototypes. The client provided feedback on aspects such as balance and grip feel. This iterative process was essential in fine-tuning the final product design.

-

Production Process: With prototypes approved, production was meticulously scheduled. Every step—from material sourcing to final quality checks—was logged. The manufacturing process adhered to a stringent timeline, ensuring the client’s market launch date was met.

-

Quality Assurance: Comprehensive quality control measures were applied, including both automated tests and manual inspections, confirming that each racket achieved the desired performance metrics.

-

Timely Delivery: The fully customized padel rackets, complete with branding and custom printing, were delivered on time, enabling the brand to secure a competitive edge in the market.

This case study demonstrates that with clear communication, thorough planning, and robust quality control, an OEM partnership can yield high-quality products that meet market demands and drive brand success.

In summary, placing your first OEM padel racket order involves several critical steps. You must define clear specifications, understand the detailed production process, prioritize quality control, and plan for potential challenges. By doing so, you can reduce risks associated with production delays and cost overruns while ensuring that the final product aligns with performance standards and branding requirements.

Here are the key actionable recommendations for procurement professionals:

- Develop a Detailed Specification Sheet: List all customization requests, design specifications, and performance criteria.

- Engage in Regular Communication: Maintain open channels with your OEM partner to ensure that production milestones are met.

- Understand Lead Times and Cost Factors: Balance the trade-offs between rapid production and high-quality materials or customization complexity.

- Implement Quality Assurance Protocols: Insist on detailed quality checks and request sample outputs before full-scale production.

- Plan for Unexpected Delays: Build a buffer in your supply chain schedules to accommodate potential setbacks.

Embracing these strategies can help transform the challenges of OEM padel racket manufacturing into strategic advantages, ensuring a smooth ordering process and a high-performing final product that meets both market expectations and your brand’s identity.

Q: How to choose the first padel racket?

A: Choosing your first padel racket involves considering factors such as the racket's shape, weight, balance, handle size, and materials. Start by identifying what fits your playing style—for instance, a round or teardrop shape can provide a balance of control and power. Ensure that the materials used match the performance and durability requirements you expect.

Q: What padel racket to get for beginners?

A: For beginners, a round or teardrop shaped padel racket is ideal as it offers enhanced control and accuracy. A mid-weight racket, typically between 360-370g, is recommended to provide a balanced mix of power and maneuverability during play.

Q: How often should you get a new padel racket?

A: The frequency of replacing your padel racket depends on usage intensity. Generally, it is advisable to update your racket every 6 to 9 months to ensure optimal performance, as regular play can cause gradual wear and affect the racket’s balance and structural integrity.

-

OEM padel rackets: Click to learn how original equipment manufacturing (OEM) works in the sporting goods industry, including its benefits for branding and market expansion. ↩ ↩

-

Customization options: Click to explore various customization methods and design strategies that allow businesses to tailor products to specific brand or consumer needs. ↩ ↩

-

Production lead times: Click to understand how lead times are calculated and managed in manufacturing, and how they impact market delivery schedules. ↩ ↩ ↩2

-

Quality control: Click to delve into the quality control processes essential for ensuring product reliability and meeting industry standards. ↩ ↩ ↩2

-

Advanced production techniques: Click to discover modern manufacturing methods that enhance product performance and consistency through technological innovation. ↩ ↩