Padel rackets are produced through a combination of advanced production techniques, quality control measures, and customization processes that ensure performance, durability, and precise engineering. In this article, we break down each step of the manufacturing process used in China by industry leaders like NEX Padel, discuss the challenges and solutions, and provide data-driven insights to help procurement managers make informed sourcing decisions.

Manufacturing premium padel rackets requires a deep understanding of material science, production techniques, and quality control. For procurement managers and business development executives in the sports equipment industry, selecting a reliable supplier involves evaluating several factors:

• The selection of raw materials such as glass fiber and various grades of carbon fiber (e.g., 3k, 12k, 18k)

• Advanced fabrication processes that achieve precision engineering

• Customization options ranging from racket shapes (Diamond, Round, Teardrop) to personalized branding (logos on the handle grip and cover)

• Rapid prototyping1 and industry-standard turnaround times

• Robust quality control to ensure durability and performance

These challenges are compounded by market demands for both speed and quality in production, making it paramount to partner with a manufacturer that excels in both.

At NEX Padel, the production of padel rackets follows a systematic and technologically advanced process. Below, we outline the key stages and the techniques involved:

Choosing the right materials is foundational. Two main types of fibers are used:

• Glass Fiber: Offers a cost-effective solution ideal for early-stage models and products aimed at recreational players. It provides good durability but less performance compared to carbon fiber.

• Carbon Fiber (3k, 12k, 18k): Provides exceptional precision, strength, and lighter weight. The different weaves (3k for basic performance, 12k and 18k for superior performance and rigidity) allow for tailoring racket properties to meet the needs of professional athletes and demanding users.

Below is a comparison table summarizing the characteristics of common padel racket materials:

| Material | Weave/Grade | Strength | Weight | Cost | Best For |

|---|---|---|---|---|---|

| Glass Fiber | N/A | Moderate | Heavier | Lower | Recreational/Entry-Level |

| Carbon Fiber | 3k | Enhanced | Lightweight | Moderate | Intermediate Players |

| Carbon Fiber | 12k | High | Lightweight | Higher | Professional/Advanced Use |

| Carbon Fiber | 18k | Very High | Ultra-light | Premium | Elite Performance |

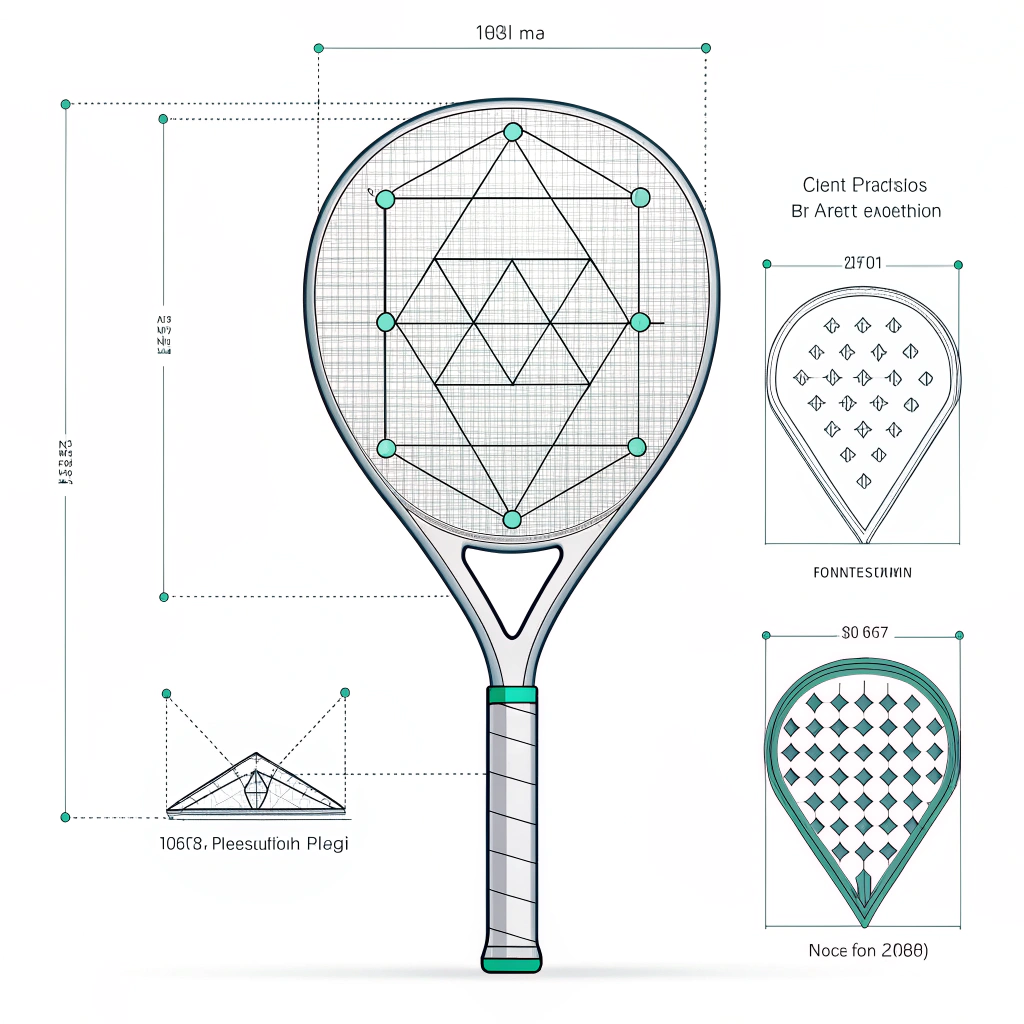

Precision Engineering and CNC machining2

The design stage utilizes computer-aided design (CAD) and CNC machining2 to create intricate shapes and designs. Every custom order, whether it is a Diamond, Round, or Teardrop shape, is developed using digital prototypes. This approach ensures that the final product meets the precise specifications agreed upon by the client.

Once the design is locked in, the production enters the molding phase. Multiple layers of materials are configured in a mold to achieve the required stiffness, flexibility, and balance. The process involves:

- Layering: Different layers for strength and flexibility are combined. For carbon fiber variants, this involves careful orientation of fibers to maximize stress distribution.

- Resin Impregnation3: Fibers are infused with resin under controlled conditions. This ensures a perfect bond and results in a homogeneous material structure.

- Curing: The composite structure is then cured in an oven or autoclave4. This step solidifies the bonding and stabilizes the final shape.

This method not only guarantees a consistent product quality but also allows for a degree of customization in material composition based on performance requirements.

After curing, the rackets undergo several finishing processes:

• Trimming and Polishing: Excess material is removed and the edges are smoothed. This step is critical for ensuring the racket is comfortable to hold and that it meets aerodynamic criteria.

• Custom Printing and Logo Application: For OEM/ODM5 orders, the surface is prepared for custom printing. This includes applying logos, colors, and other branding elements with precision.

• Attachment of Hand Grip and Handle Cover: Even the smaller components, such as the hand grip, are custom-made. High-performance adhesives and ergonomic design principles inform this process to ensure the final product is both functional and visually appealing.

Quality control is integral to every stage of padel racket production. NEX Padel implements rigorous quality checkpoints that include:

- Material Inspection: Incoming materials are tested for tensile strength, flexibility, and consistency.

- In-Process Monitoring: At each production phase, samples are taken and evaluated to verify that design specifications are being met.

- Post-Production Testing: Finished rackets undergo stress tests, balance examination, and visual inspections to ensure they meet industry standards.

Beyond the manufacturing process, supply chain reliability is maintained by leveraging strong relationships with top-tier material suppliers and logistics partners. Fast prototyping and industry-standard turnaround times are core elements in meeting both the scheduling and quality demands of global partners.

In today’s competitive market, customization is not just a bonus—it is a necessity. NEX Padel has embraced customization through:

• Product Shape Variation: Whether you require a Diamond, Round, or Teardrop profile, the advanced design process can accommodate unique shapes that suit player preferences and performance criteria.

• Branding and Aesthetics: Custom color schemes and printing allow companies to maintain brand consistency without compromising on quality or performance.

• Accessory Integration: Customization extends to accessories such as hand grips and cover designs, which can be branded to enhance marketing impact.

These tailored solutions help clients differentiate their product lineup and address niche market demands with precision.

For companies in sports equipment manufacturing, partnering with an expert like NEX Padel brings several advantages:

- High-Quality Production: Utilizing advanced production methods and stringent quality control processes ensures that every product meets high industry standards.

- Customized Solutions: Every order can be tailored to client specifications, from material selection to design and finishing touches.

- Efficient Turnaround: Quick prototyping and production schedules permit flexible responses to market changes and high-volume demands.

- Cost Efficiency: Optimized production techniques allow for competitive pricing even for premium products.

- Reliability: A seamless supply chain and robust quality assurance mean that OEM/ODM partners receive products that are consistent, reliable, and ready for market distribution.

For procurement managers evaluating manufacturing partners, consider these steps:

- Engage in a detailed discussion about material choices and production techniques to ensure alignment with your quality benchmarks.

- Request samples and detailed production timelines to verify turnaround times.

- Evaluate customization capabilities to guarantee that your brand identity is preserved across all product variants.

- Assess quality control mechanisms and track records in meeting industry standards.

By taking these steps, you can significantly reduce risk and optimize sourcing strategies, ensuring that your product range remains competitive and highly performant.

The Chinese manufacturing process for padel rackets, as executed by industry leaders like NEX Padel, is characterized by its precision engineering, advanced production techniques, and commitment to quality control. By understanding each stage from material selection to final finishing, procurement managers can appreciate the detailed processes that yield high-performance, durable, and aesthetically appealing padel rackets. These insights not only underline the technical complexity of production but also highlight the strategic benefits of partnering with experienced OEM/ODM manufacturers.

Every step, whether it is the use of advanced molding techniques or the implementation of rapid prototyping1, is geared toward ensuring that the final product meets the rich demands of both recreation and professional sports markets. The integrated use of technology and quality control protocols generates reliable products on time, making suppliers like NEX Padel a valuable partner in the competitive sports equipment landscape. If you are looking for a strategic supplier who can balance customization, quality, and turnaround efficiency, the advanced manufacturing process of Chinese producers presents a compelling case.

For further inquiries or to discuss your custom padel racket production requirements, feel free to reach out, and let us help you navigate your next strategic procurement decision.

Q: How are padel rackets produced?

A: Padel rackets are produced using advanced techniques that include material selection (glass fiber and various grades of carbon fiber), precision CNC machining for shaping, and a layered molding process followed by meticulous finishing and customization.

Q: What quality control measures are used in padel racket production?

A: Quality control measures include material inspection, in-process checks, and post-production testing such as stress tests, balance examinations, and visual inspections to ensure each product meets industry standards.

Q: Can padel rackets be customized in OEM/ODM production?

A: Yes, padel rackets produced through OEM/ODM processes allow for extensive customization, including different shapes (Diamond, Round, Teardrop), color schemes, printing logos, and even custom accessories such as hand grips and covers.

-

Rapid prototyping: Discover how rapid prototyping accelerates product development cycles by creating quick, cost-effective, and functional prototypes, allowing for iterative design improvements. ↩ ↩ ↩2

-

CNC machining: Read this article to understand how computer numerical control machining automates manufacturing with precision and repeatability, enhancing production efficiency and reducing errors. ↩ ↩ ↩2

-

Resin Impregnation: Explore the resin impregnation process, which infuses fibers with resin to create a uniform, high-strength composite material essential for quality-controlled production. ↩ ↩

-

autoclave: Learn more about autoclaves and how they are used in the curing process to apply controlled heat and pressure for superior composite bonding and material performance. ↩ ↩

-

OEM/ODM: Click here to learn about the differences between Original Equipment Manufacturers and Original Design Manufacturers, and how these models affect product customization and sourcing strategies. ↩ ↩