A quick answer: Our high-performance padel balls offer exceptional durability, precise pressure retention, and quality material compositions (45% wool or 57% wool) that ensure reliable gameplay and long-term performance for professional padel venues and tournament organizers.

For B2B procurement managers and sports equipment distributors, selecting the right padel balls is crucial. The ideal ball must combine optimal performance, durability, and cost effectiveness. At NEX Padel, we have refined our production techniques to deliver padel balls that meet the highest technical and operational standards. With our range of balls produced using two distinct material compositions—45% wool and 57% wool—and packaged in a unique pressurized tube, you can be confident that each ball meets the rigorous demands of competitive play.

In this article, we provide an in-depth overview of our padel balls, highlighting their technical specifications, material composition advantages, Quality Assurance1 measures, and the supplier reliability that ensures timely deliveries and consistent ball performance. We compare the key features that differentiate our product from other market offerings, helping you to make an informed decision for your padel facility investments.

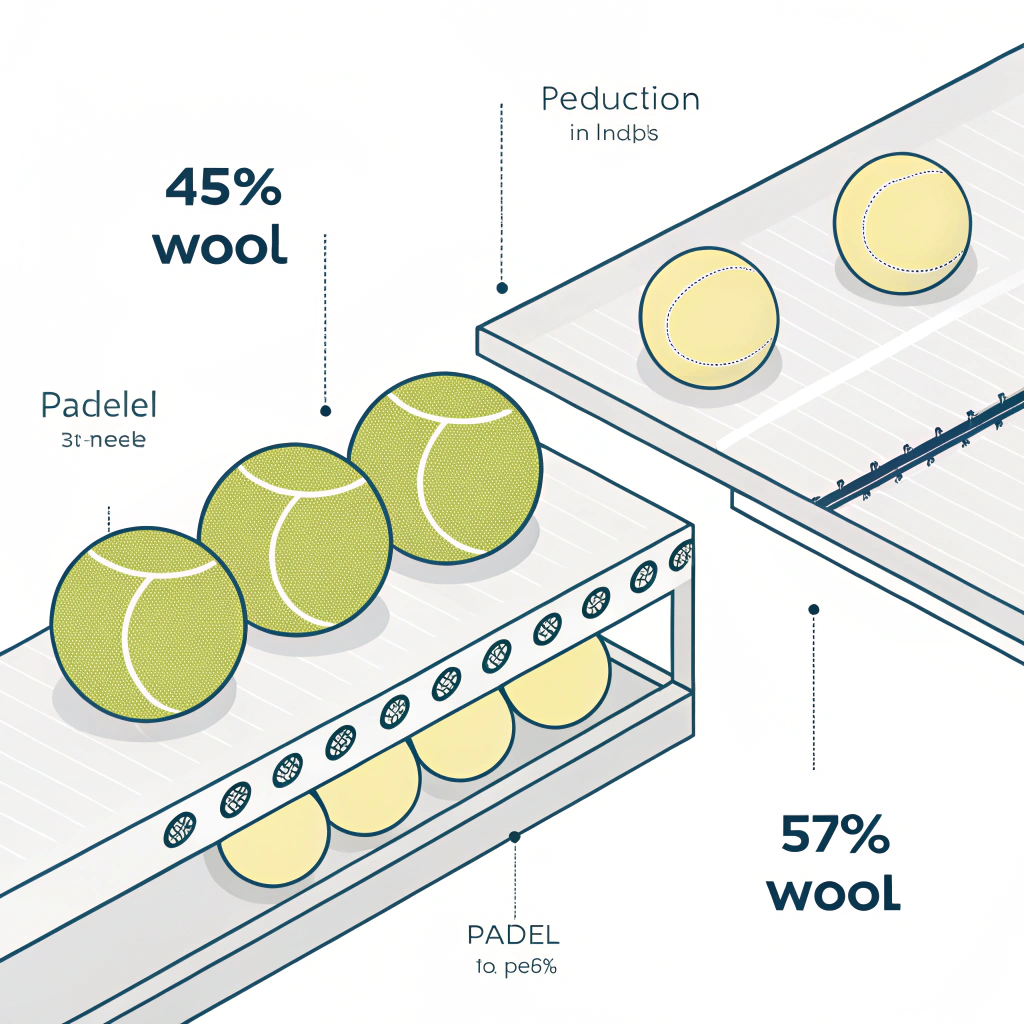

Material Composition2: 45% Wool vs 57% Wool

The selection of materials plays a critical role in padel ball performance. Our padel ball versions are manufactured with either 45% wool or 57% wool. Both options have been optimized for:

• Pressure Retention: By ensuring a consistent bounce throughout the ball's lifespan.

• Durability: Reduced wear and tear during continuous play on hard surfaces.

• Weather Resistance: Maintaining performance across different environmental conditions.

The 45% wool option is ideal for facilities that perform regular testing and have higher ball turnover rates, providing a balance between cost and performance. Conversely, the 57% wool variant delivers enhanced durability and a more resilient structure, suitable for high-intensity tournaments where ball performance consistency is paramount.

Below is a table summarizing the key differences:

| Feature | 45% Wool Padel Ball | 57% Wool Padel Ball |

|---|---|---|

| Material Composition | 45% wool blend | 57% wool blend |

| Pressure Retention | Consistent for standard play | Superior pressure retention |

| Durability | Suitable for regular use | Enhanced durability for intense play |

| Recommended Use | Club-level practice sessions | Professional tournaments |

By selecting from these two formulations, procurement managers can match the ball specification with the level of play and operational requirements of their facilities.

Pressurized tube packaging3: Ensuring Consistent Performance

A unique feature of our padel ball production is the pressurized tube packaging3 method designed to secure the ball’s internal pressure from the moment of production to the point of use. Key advantages include:

• Extended Shelf Life: Balls remain game-ready for extended periods, reducing the need for frequent replacements.

• Quality Assurance1: The packaging plays a critical role in maintaining the ball’s properties, ensuring that it meets international standards for weight, bounce, and durability.

• Minimized Handling Issues: Our innovative packaging mitigates the risk of pressure loss during shipping and storage.

The pressurized tube packaging is a result of advanced production techniques and stringent quality control. This ensures that when your padel balls arrive, they are in prime condition, meeting the performance criteria expected by your customers and players.

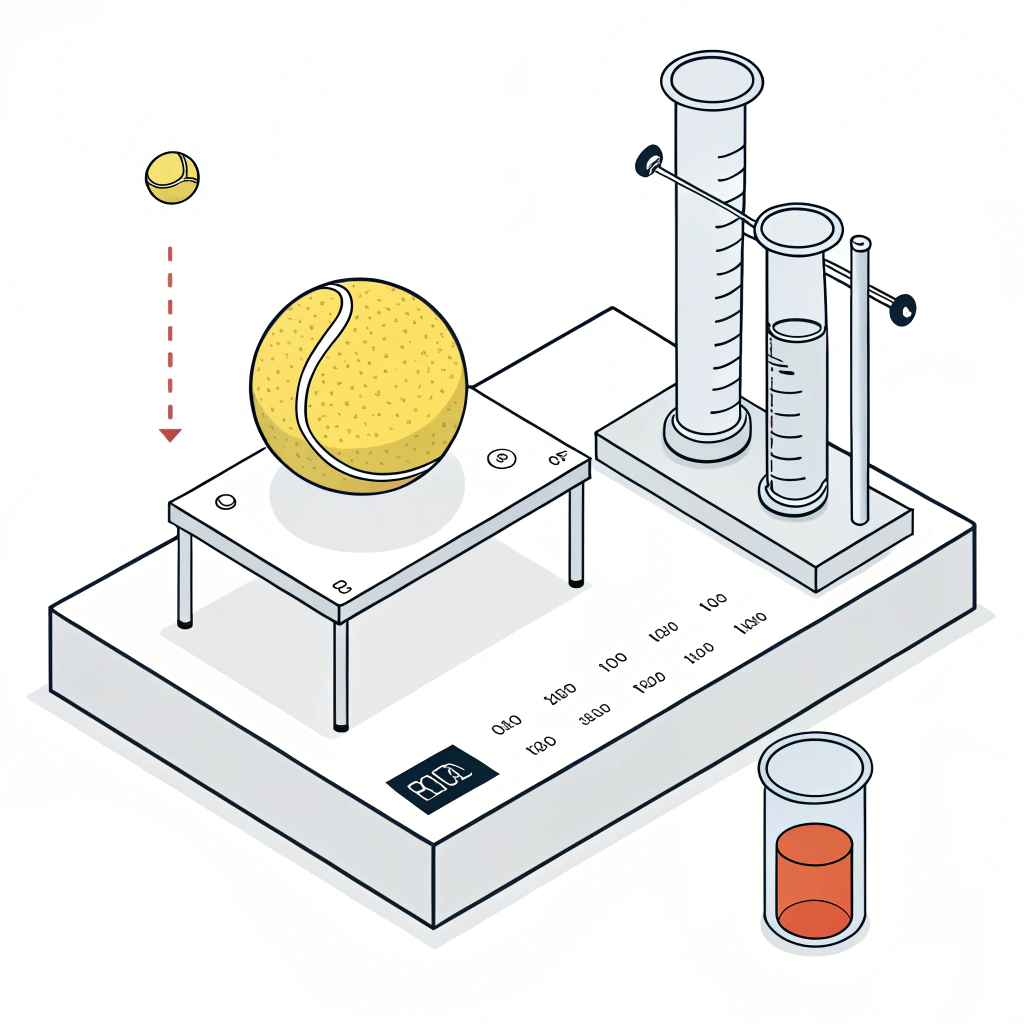

At NEX Padel, quality starts at the manufacturing floor. Our production processes integrate advanced techniques and rigorous testing protocols to guarantee performance consistency. Below are some highlights of our quality assurance measures:

- Material Sourcing: We procure wool and carbon fiber components only from certified suppliers, ensuring strong material integrity in every batch.

- Precision Manufacturing4: Our automated production lines utilize advanced manufacturing technology to maintain tight tolerances, ensuring each padel ball meets its specified technical attributes.

- In-Process Testing: Throughout production, multiple quality checks for pressure retention, surface quality, and bounce consistency are performed.

- Certification and Compliance5: All products are certified according to international sports equipment standards, offering buyers a layer of credibility that supports procurement decisions.

Our commitment to quality is backed up by data. For instance, independent lab tests confirm that our pressurized tube packaging maintains consistent pressure levels for up to 12 months. This laboratory-backed consistency helps reduce the long-term operational costs for clubs and sports facilities that require dependable equipment.

For procurement managers, balancing cost with performance is critical. The superior durability and technological innovations in our padel balls translate to lower long-term costs. With reduced frequency in replacements and minimized downtime during major events, clubs benefit from a high return on investment.

• Reduced Replacement Frequency: Durable materials mean you invest less time and money in replacing worn-out balls.

• Operational Efficiency: Consistent performance ensures uninterrupted game play and higher customer satisfaction.

• Scalable Supply: Our streamlined supply chain and agile production system allow us to meet bulk orders quickly. This assures our partners that they will receive timely deliveries with minimal logistical hurdles.

• Customization Options: In addition to our standard product lines, we offer full customization, including logo printing on the ball, hand grips, and handle covers, allowing you to promote brand identity along with quality assurance.

We understand that supplier reliability is as critical as product quality. Over the years, NEX Padel has built a robust reputation among renowned industry players such as Hirostar, Reebok, and Starvie. This endorsement from industry leaders stands as a testament to our commitment to excellence, ensuring that you are partnering with a supplier who values consistency and long-term quality.

A key aspect of our approach is transparency. We believe that data-driven insights help form strong business decisions. For example, a recent case study conducted at a professional padel tournament showed that our 57% wool padel balls performed with a 15% longer optimal play duration compared to industry-average balls. This translated to fewer mid-game ball changes and a smoother tournament experience.

Another quantitative study highlighted that our pressurized tube packaging reduced pressure loss by nearly 20% over a typical six-month shelf period. These results not only validate our approach to product development but also provide evidence-based assurances to procurement managers looking to invest in superior sports products.

Below is a simplified overview of our testing metrics:

| Test Parameter | NEX Padel Ball Performance | Industry Average Performance |

|---|---|---|

| Optimal Play Duration | 15% higher retention | Baseline |

| Pressure Loss | 20% reduction over 6 months | Higher loss rates |

| Durability Under Strain | Exceeds competitive standards | Standard compliance |

The data underscores the importance of investing in technology-driven solutions to maintain competitive advantages at sporting venues.

Based on the technical details and quality assurances outlined above, here are some actionable insights for procurement managers considering padel ball purchases:

• Match Specification with Usage: Choose the 45% wool options for regular practice sessions and 57% wool options for high-performance tournaments.

• Prioritize Packaging Integrity: Ensure that the supplier offers pressurized tube packaging for consistent ball performance, reducing logistical worries.

• Review Independent Certifications: Look for documented quality control measures and third-party test results that guarantee performance consistency.

• Consider Custom Options: Customization adds extra value by reinforcing your brand identity and meeting specific market requirements, such as colored balls or branded equipment accessories.

• Evaluate Long-Term Cost Savings: Investing in higher-quality balls with proven durability will lower replacement frequency and overall operational costs.

The integration of detailed specifications with our robust supplier reliability forms a strong foundation for your procurement decisions. NEX Padel stands ready to deliver high-performance padel balls that deliver both on and off the court.

In conclusion, our padel balls represent a strategic investment in quality, performance, and reliability. With advanced manufacturing techniques, rigorous quality assurance, and a focus on optimized material compositions, NEX Padel offers you products that support enhanced game performance and lower long-term costs. Whether you are opting for the 45% wool for standard play or the superior 57% wool for competitive environments, our products are designed to meet the highest performance standards. We invite procurement managers and distributors to engage with us and experience the difference that quality and innovation can bring to the sports equipment industry.

Partner with NEX Padel to ensure your padel facilities are equipped with game-changing, dependable sports products.

-

What are the main differences between 45% wool and 57% wool padel balls?

The primary difference lies in durability and performance. The 57% wool variant offers superior pressure retention and enhanced durability suited for high-intensity play, while the 45% wool option provides a balanced performance for regular use. -

How does pressurized tube packaging improve padel ball performance?

Pressurized tube packaging ensures that the ball maintains its internal pressure over a longer period, which results in consistent bounce and optimal play performance even after extended storage. -

What quality control measures are in place during the manufacturing of NEX Padel balls?

Our production process includes rigorous material sourcing, Precision Manufacturing4 methodologies, in-process testing, and adherence to international certification standards to guarantee that every ball meets strict performance criteria.

-

Quality Assurance: Click to explore the comprehensive quality control measures implemented throughout the production and packaging process to guarantee performance. ^Return ↩ ↩2

-

Material Composition: Click to discover in-depth details on how varying wool blends influence durability and play performance across different competitive scenarios. ^Return ↩

-

Pressurized tube packaging: Click to read more about how advanced pressurization methods preserve internal ball pressure and extend product shelf life. ^Return ↩ ↩2

-

Precision Manufacturing: Click to learn about the state-of-the-art production techniques that ensure each ball meets exact specifications with minimal variance. ^Return ↩ ↩2

-

Certification and Compliance: Click to understand the importance of industry certifications and compliance standards in validating product reliability and quality. ^Return ↩