NEX Padel offers a comprehensive OEM manufacturing solution1 for padel rackets that blends advanced production techniques, a range of high-quality materials, and Customization Options2 to meet the diverse needs of B2B purchasers. In this article, we detail the key factors to consider when choosing an OEM supplier, conduct a detailed comparison of features, and explain how NEX Padel stands out as a trusted partner for your bulk padel equipment orders.

The padel market is experiencing dynamic growth worldwide, driven by increasing participation in the sport and rising demand for high-performance equipment. For procurement managers and product sourcing specialists, identifying a reliable OEM partner is critical. The challenge often lies in evaluating suppliers based on product quality, customization capabilities, pricing, and fulfillment speed. In a competitive market, the right supplier must combine technical excellence with consistent delivery—attributes that are especially important for companies seeking long-term, cost-effective partnerships.

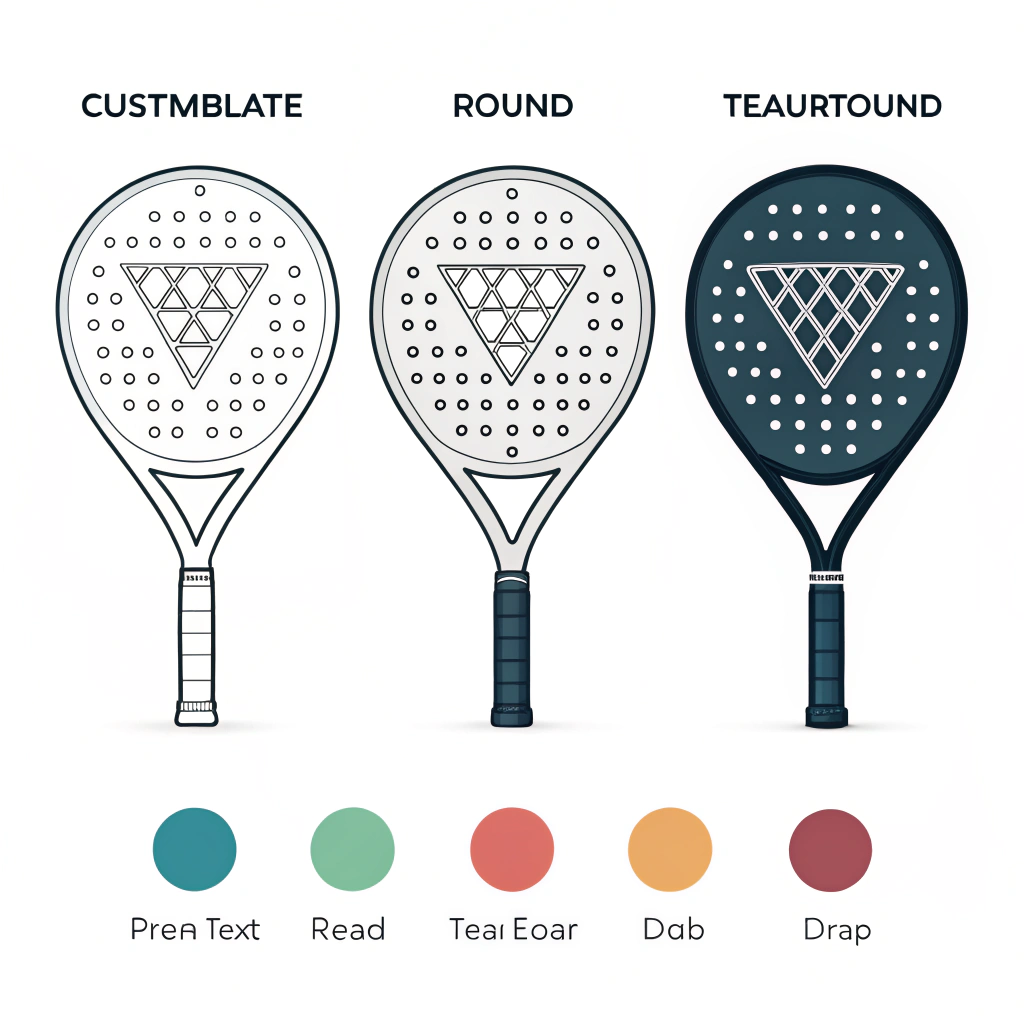

An OEM supplier in this space must be comfortable handling a variety of materials, from fiberglass to advanced carbon fibers3 like 3k, 12k, and 18k. They must also support bespoke requirements such as custom racket shapes (Diamond, Round, Teardrop) and branding on components like hand grips and racket covers. With these criteria in mind, decision-makers must perform a detailed analysis and comparison before entering a contract.

When comparing suppliers, the following aspects should be carefully reviewed:

-

Product Quality: A high-performance padel racket should offer precision, durability, and balanced weight distribution. Materials used—whether fiberglass or various grades of carbon fiber—can significantly affect these parameters.

-

Customization Options: The level of product customization, including shape (Diamond, Round, or Teardrop), color options, logo placement, and even customized hand grips, is essential. This flexibility can be a key differentiator, especially for brands looking to offer unique products.

-

Production Techniques: Technology-driven manufacturing processes ensure consistency and reduce error rates. Suppliers that use advanced assembly methods and quality control strategies can guarantee better product performance and longer service life.

-

Order Turnaround Time: For a procurement manager, fast turnaround times and reliable delivery schedules are crucial. Early sampling, iterative adjustments, and prompt shipment are key attributes that establish supplier trust.

-

Pricing and Bulk Order Capabilities: Competitive pricing in conjunction with the ability to handle large orders without compromising quality is important for profitability and inventory management.

-

Ancillary Products Supply: Some suppliers offer a broader range of products like padel balls. Partnering with a supplier who can offer both rackets and balls might streamline processes and improve supply chain efficiency.

A side-by-side comparison can clarify which supplier best meets your needs. The table below summarizes core features compared against common benchmarks in the industry:

| Criteria | NEX Padel Advantage | Other Suppliers |

|---|---|---|

| Material Quality | Variety from Fiberglass to 3k, 12k, and 18k Carbon Fiber ensuring high performance and durability | Limited material options; may use lower-grade carbon fiber or outdated materials |

| Customization Options | Offers Diamond, Round, Teardrop shapes with full logo printing and customizable hand accessories | Standard models with minimal customization |

| Production Techniques | Advanced, automated production with stringent quality control and rapid prototyping | Traditional manufacturing processes with longer lead times |

| Order Turnaround Time | Fast sampling and delivery cycles to meet market demands | Longer cycle times, less flexibility with urgent orders |

| Pricing & Bulk Orders | Competitive pricing even for large volume orders with cost-effective solutions | Not optimized for bulk order discounts; may have less transparent pricing |

| Ancillary Product Supply | Provides padel balls in two wool compositions with guaranteed pressure retention | Limited or no ancillary product offerings |

This comprehensive table is designed to help decision-makers in B2B procurement quickly assess the areas where NEX Padel outperforms competitors. The detailed side-by-side comparison illustrates not only performance benefits but also operational advantages that can have a significant impact on end-user satisfaction.

At NEX Padel, every step of the padel racket manufacturing process is refined to meet strict quality standards. Our production process includes:

-

Material Selection and Testing: We source a range of premium materials and rigorously test each batch to ensure they meet performance standards. By leveraging advanced composite materials, we achieve a balance of weight and durability.

-

Precision Manufacturing: Our factory in Jiaxing, Zhejiang, China uses cutting-edge machines that help produce consistent and precise dimensions for each racket. This ensures the performance you expect from a high-quality padel racket.

-

Quality Control Processes: We implement multiple quality checkpoints throughout the production cycle. Each racket undergoes detailed inspection for structural integrity, balance, and finishing quality. This stringent approach minimizes defects and guarantees that every product leaving our facility reflects our high standards.

-

Rapid Prototyping4 and Sampling: Our ability to quickly create samples and adjust production according to client feedback is a critical factor in fast delivery. This agility in production reinforces our commitment to meeting tight deadlines without compromising on quality.

A key differentiator is our capability to accommodate both standard bulk orders and completely customized orders. Whether you require a specific design for a promotional event or a unique configuration for a product line, our flexible approach ensures that every need is met while maintaining consistent quality.

The modern padel market thrives on differentiation. With sports equipment retailers increasingly seeking unique products to attract customers, the flexibility to offer customized padel rackets is a powerful competitive advantage. At NEX Padel, we provide a wide range of customization options:

Racket Shapes:

- Diamond Shape: Known for its power and precise shot-making capacity, the Diamond model is ideal for advanced players.

- Round Racket: Offering more control and balance, the round racket is a popular choice for beginners and intermediates.

- Teardrop Racket: A balanced option that offers both power and control, suitable for versatile play styles.

Branding and Personalization:

- Custom printing and color selections on both the racket face and the handle accessories.

- Ability to embed your company logo on the racket frame, hand grip, and racket cover, ensuring consistent brand visibility.

- Tailor-made designs to align with seasonal trends or promotional events.

Price Point and Material Customization:

- Depending on market demands, you can opt for different material grades. For instance, higher-end models use 12k or 18k carbon fibers for enhanced stiffness and power transfer, while more cost-effective models might use fiberglass or 3k carbon fibers.

This level of customization not only helps differentiate your brand but also allows you to better target your consumer demographic. In an industry where subtle differences in design can have a huge impact on performance, such granular control over racket specifications is invaluable.

Streamlined Fulfillment and Supply Chain Efficiency5

Another key factor that distinguishes successful OEM partnerships is efficient supply chain management. Rapid prototyping, quick adjustment cycles, and reliable logistics are pillars of a robust fulfillment process. NEX Padel prides itself on its ability to manage large-scale orders with consistency and precision:

- Fast Turnaround: Our streamlined approval and production process minimizes downtime, ensuring that orders are fulfilled quickly.

- Scalability: Whether it's a small batch of prototypes or a bulk order across multiple retail outlets, our production capacity is tailored to handle varying order volumes without sacrificing quality.

- Global Logistics: With our strong network of logistics partners, we guarantee timely and secure delivery of products to international markets.

Ensuring that your supply chain runs smoothly is not just about meeting deadlines; it's about building trust with your own clientele by ensuring that the products consistently hit the market in top condition.

For procurement managers and product sourcing specialists evaluating OEM padel racket suppliers, thorough comparison and evaluation of key factors are essential. NEX Padel stands out for its advanced manufacturing techniques, stringent quality control, extensive customization options, and reliable turnaround times. These attributes come together to create a unique value proposition that can help your business thrive in a competitive market.

In conclusion, when you are considering a long-term manufacturing partner for padel equipment, focus on suppliers that:

- Provide a wide range of material options and consistent product quality.

- Offer flexible customization to meet unique market demands.

- Employ advanced production techniques to ensure precision and durability.

- Guarantee reliable and fast delivery times.

By choosing a supplier like NEX Padel, you not only secure a high-performance product but also gain a partner committed to your success through continuous innovation and operational excellence. We invite you to explore the possibilities of a partnership and see how our specialized services can elevate your product offerings in the growing padel market.

-

What factors should be considered when selecting an OEM supplier for padel rackets?

A solid supplier should offer high-quality materials, advanced production methods, extensive customization options, competitive pricing for bulk orders, and reliable turnaround times. These factors help ensure that you receive a product that meets both performance and market expectations. -

How does NEX Padel ensure the high-performance of its padel rackets?

NEX Padel employs stringent quality control measures, precise manufacturing techniques, and uses a variety of premium materials like advanced carbon fibers to deliver rackets that offer both durability and exceptional performance. -

What customization options are available for OEM padel rackets?

NEX Padel offers a range of customization options including various racket shapes (Diamond, Round, Teardrop), custom color printing, logo placement on the frame and hand grips, and even adjustments to the material composition to suit different performance and price needs.

-

OEM manufacturing solution: Click to access an article that explains the concept of OEM (Original Equipment Manufacturer) partnerships, detailing how manufacturers collaborate with brands and the benefits of streamlined production processes. ↩

-

Customization Options: Click to understand the importance of customization options in manufacturing, including how tailored products can address niche market demands and foster stronger brand differentiation. ↩

-

Advanced carbon fibers: Click to learn more about advanced carbon fibers, including different grades (3k, 12k, 18k), their properties, and how they enhance product performance in high-stakes manufacturing. ↩

-

Rapid Prototyping: Click to explore rapid prototyping techniques, including its role in accelerating production cycles, reducing development time, and increasing product accuracy. ↩

-

Supply Chain Efficiency: Click to delve into strategies for optimizing supply chain efficiency, covering logistics, process automation, and methods to ensure consistent and timely product delivery. ↩