The quick answer: Expensive padel rackets command premium prices due to their advanced materials1, meticulous manufacturing processes, and long-term durability benefits that provide superior performance and value in the competitive sports equipment market.

In today’s competitive sporting goods industry, high-performance padel rackets are more than just sports equipment—they represent a blend of innovative design, state-of-the-art materials, and precision manufacturing. For procurement professionals seeking to justify investments in quality padel equipment, understanding what drives these premium prices is essential. This article explains the cost drivers behind padel rackets while offering a detailed cost-benefit analysis2 to support reliable, performance-driven purchasing decisions.

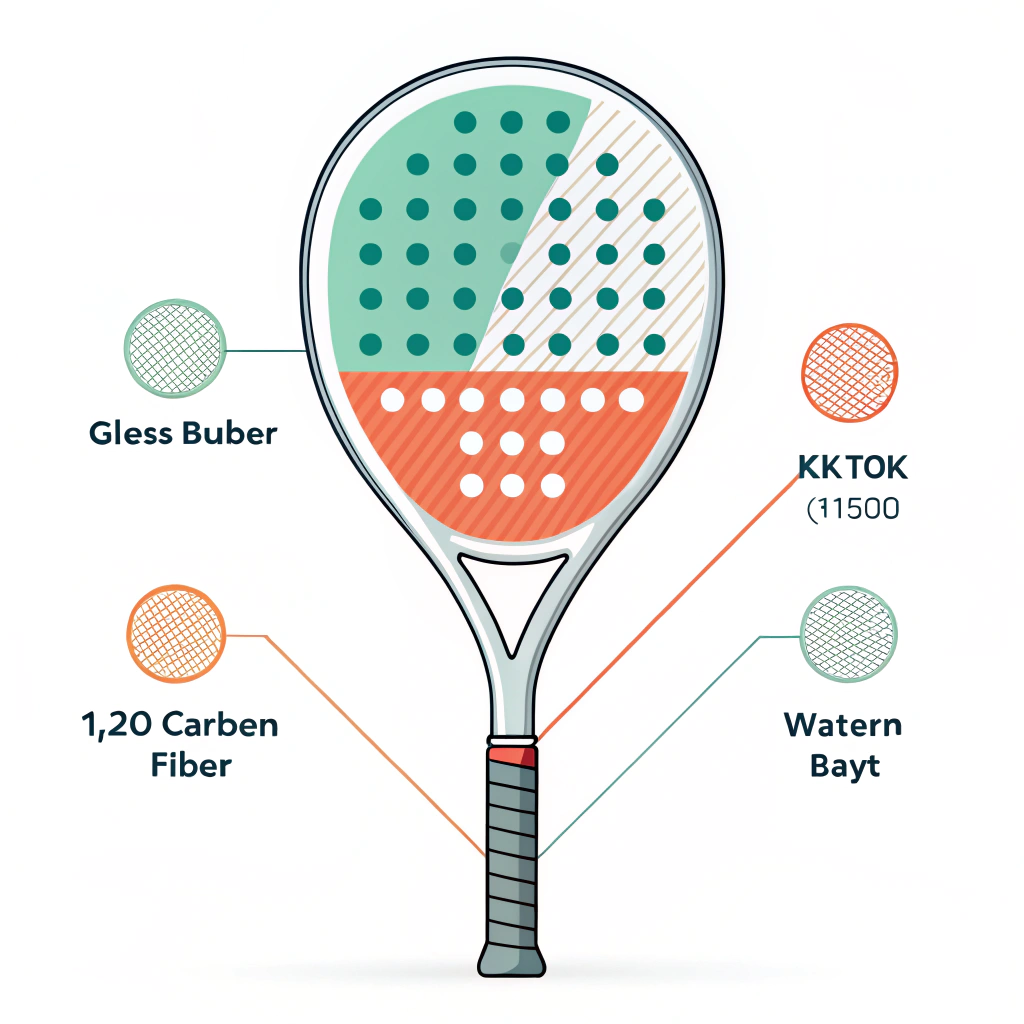

Padel rackets differ significantly from other sports equipment due to their unique design and rigorous performance requirements. Unlike tennis rackets that primarily consist of a frame and grip, padel rackets are constructed as solid pieces. They must withstand thousands of direct impacts during regular use. The manufacturing process involves:

- Advanced material selection: Utilizing glass fiber, as well as various grades of carbon fiber (3k, 12k, and 18k), each choice offers a balance of flexibility, strength, and cost-effectiveness.

- Precision engineering3: Every production stage— from cutting raw materials to assembling and finishing the racket—must adhere to strict tolerances. This creates a product that not only performs under pressure but also retains its characteristics over many games.

- Customizable production4: Beyond standard designs (Diamond, Round, and Teardrop), high-end manufacturers offer customization, from shape adjustments to finish and logo placements on hand grips and overgrips.

Such meticulous production methods ensure that manufacturers like NEX Padel, with extensive expertise and a reputation for quality, deliver rackets that meet demanding performance standards while justifying a higher price tag.

At the core of every premium padel racket are the materials that determine its performance, longevity, and playability. Different grades of carbon fiber and composite materials influence key attributes such as stiffness, weight distribution, and vibration dampening. Let’s examine the main materials used:

| Material Type | Characteristics | Performance Impact | Application Scope |

|---|---|---|---|

| Glass Fiber | Lower cost with good flexibility | Enhances lightweight properties; moderates shock | Entry-level to mid-performance models |

| 3k Carbon Fiber | Fine weave structure with improved strength | Offers a balance of power and control; stable feel | Advanced amateur and professional models |

| 12k/18k Carbon Fiber | Denser construction for optimum rigidity and impact absorption | Maximizes durability and racket response; minimal vibration | High-end competition level |

By leveraging these material technologies, manufacturers can tailor the balance between power, control, and durability. For B2B buyers, understanding these differences is critical as it supports decisions aimed at meeting both performance needs and long-term cost savings. Investments in superior materials can reduce the frequency of replacements due to breakage or performance degradation.

A premium padel racket is not only about high-grade materials but also about how these materials are transformed into a finished product. The manufacturing process involves several critical steps:

- Material Preparation: Cutting and molding of carbon fiber and glass fiber materials require laser precision to ensure consistent quality.

- Layup and Curing: Layered construction using specific resin systems ensures each racket meets desired stiffness and damping properties. Advanced curing techniques optimize material performance and reduce defects.

- Trimming and Finishing: Final touches include precise trimming and application of custom prints or logos. This step often involves automated as well as hand-finished processes ensuring that details, such as the design or brand mark, meet quality standards.

- Quality Assurance5: Rigorous testing procedures ensure that each racket can withstand thousands of impacts. Standardized tests based on international sport equipment guidelines are frequently applied, ensuring the product meets both safety and performance criteria.

Precision in these processes results in a product that not only performs exceptionally but also offers long-term durability. A robust quality assurance mechanism minimizes production errors, which is vital for companies like ours to maintain strong relationships with globally recognized brands.

For procurement managers at sports equipment distributors, understanding the cost versus benefit equation of investing in superior padel rackets is paramount. While the initial outlay may be higher than that of standard rackets, the return on investment becomes evident over time.

- Material Costs: The use of premium materials like 18k carbon fiber increases production costs but also translates into enhanced performance and longevity.

- Manufacturing Complexity: High-precision processes, customizations, and stringent quality tests necessitate higher production expenses.

- Customization and Branding: Bespoke designs, including custom printing and logo placements, add value to the product and cater to specialized market needs.

- Durability and Performance: High-performance materials and expert manufacturing lead to rackets that maintain their playability longer, reducing replacement frequency.

- Brand Differentiation: Offering a high-quality, customizable product can be a key differentiator in a crowded market, appealing to elite users and enhancing overall brand positioning.

- Cost Efficiency in the Long Run: A more durable product minimizes warranty claims and returns, thus justifying higher upfront costs with long-term savings.

Below is a simplified table that illustrates a typical cost and benefit comparison between standard padel rackets and premium models:

| Factor | Standard Racket | Premium Racket |

|---|---|---|

| Initial Material Quality | Moderate | High-grade (3k, 12k, 18k carbon) |

| Manufacturing Precision | Basic processes | Advanced, automated precision |

| Customization Options | Limited | Extensive (custom shapes, prints, logos) |

| Longevity & Durability | Lower; frequent replacements | Higher; fewer replacements |

| Total Cost of Ownership | Low initial cost, high long-term costs | Higher initial cost, better long-term savings |

This table shows that while the premium option carries a higher upfront investment, the overall cost efficiency improves due to fewer replacements and enhanced performance benefits.

One unique advantage within the premium padel equipment market is the ability to offer customized products. When distributors or clubs procure these rackets, they gain access to benefits such as:

- Tailored Aesthetics and Performance: Custom shapes (Diamond, Round, or Teardrop), print details, and color schemes not only elevate product aesthetics but also help fine-tune performance attributes.

- Brand Consistency: Custom logos on the racket, hand grips, or overgrips reinforce brand recognition. This is especially valuable for retailers seeking to maintain a consistent brand identity or for clubs looking to have personalized gear for their members.

- Adaptability to Market Demand: With the ability to switch between different carbon fiber compositions, manufacturers can cater to various player levels—from recreational players needing more forgiving materials to professionals who demand high responsiveness.

- Regulatory and Standards Compliance: Premium padel rackets are produced following strict international standards and sport equipment regulations, ensuring safe, reliable products for a global market.

Over time, these factors contribute to a strong value proposition, helping distributors justify higher prices through enhanced product appeal and overall longevity.

In summary, the premium pricing of padel rackets is a reflection of the superior materials, rigorous manufacturing processes, and extensive customization options that manufacturers like NEX Padel offer. These rackets are engineered to deliver enhanced performance, extended durability, and brand differentiation—making them a worthy investment under a long-term cost-benefit analysis model.

For procurement managers evaluating their inventory or considering new product lines, here are key recommendations:

- Assess the overall total cost of ownership by taking into account long-term durability and reduced replacement rates.

- Evaluate customization possibilities to enhance brand differentiation and market appeal.

- Consider partnering with manufacturers who emphasize advanced materials and quality assurance processes. This can lead to enhanced customer satisfaction and lower after-sales costs.

- Stay updated with international sport equipment standards to ensure that all products meet current regulatory and performance demands.

By focusing on these factors, sports equipment distributors and clubs can align their purchasing decisions with long-term performance, cost efficiency, and enhanced competitive positioning.

Are expensive padel rackets worth it?

Yes. Although higher-priced padel rackets require a larger initial investment, their advanced construction, premium materials, and enhanced durability ensure that they offer superior performance over time. This long-term reliability justifies the expense for players and distributors alike.

Why are paddle ball rackets so expensive?

The high cost is mainly driven by their complex manufacturing process. Unlike simpler racket designs, padel rackets are solid structures that must withstand thousands of impacts. Advanced materials like various grades of carbon fiber, along with precision production techniques, contribute to higher production costs, thus driving up the price.

How much should I spend on a padel racket?

The price range can vary significantly depending on performance needs and customization options. For advanced performance and durability, many experts recommend starting at around £170, with higher-end models reaching over £400. Ultimately, the optimal spending amount depends on the specific requirements and preferences of the player.

-

advanced materials: Click to learn more about state-of-the-art substances used to enhance performance, durability, and weight distribution in high-end sporting goods. ↩

-

cost-benefit analysis: Click to discover methods for evaluating long-term value, balancing initial investment versus sustained performance and savings. ↩

-

Precision engineering: Click to explore the techniques and meticulous processes ensuring every component meets strict tolerances for optimal performance. ↩

-

Customizable production: Click to understand how tailored manufacturing processes allow for bespoke designs that suit specific performance and aesthetic requirements. ↩

-

Quality Assurance: Click to get insights into standardized testing and quality control measures that guarantee reliability and safety in premium sports equipment. ↩