Carbon fiber integrated into padel rackets delivers enhanced strength, control, and durability—key qualities for high-performance play and smart procurement decisions.

In today’s competitive sports equipment landscape, procurement managers and product development leads face the challenge of balancing cost with superior performance. With technological advances, Carbon fiber1 has emerged as a groundbreaking material in padel racket manufacturing, offering an ideal mix of strength, stiffness, and weight reduction. This article examines why integrating carbon fiber into padel rackets justifies higher investment costs, explains its technical benefits, and presents a structured solution for incorporating advanced materials into your equipment lineup.

The sports equipment industry continuously wrestles with the need to provide products that consistently deliver performance enhancement and long-term durability. For padel rackets, the material selection is critical. Traditional materials like fiberglass and lower-grade composites may offer acceptable performance, but they often fall short when compared to the technical advantages that carbon composite2 materials provide. Procurement professionals must ask:

- How do different materials compare in a cost-benefit analysis?

- Can investing in higher-cost materials like carbon fiber truly result in better performance outcomes?

- What are the long-term benefits in durability and design flexibility when switching to carbon fiber?

The core issue centers on material effectiveness. Today’s advanced padel racket manufacturing has witnessed an increase in sophisticated techniques such as using 3k, 12k, and 18k carbon fiber configurations3 to optimize each racket’s performance. However, the higher initial investment demands a thorough understanding and justification using real-life data and technical analysis.

Several factors drive the increasing preference for carbon fiber in high-performance sports equipment:

-

Enhanced Strength and Durability: Carbon fiber’s molecular structure makes it extremely strong relative to its weight. For padel rackets, this translates into improved power transfer, ensuring that each stroke maintains its integrity over prolonged use.

-

Improved Stiffness and Control: A stiffer racket allows for more immediate energy return upon striking the ball. Carbon fiber rackets deliver increased precision, which is essential for competitive play. With a stiffer structure, the racket can offer better control, even during high-speed maneuvers.

-

Weight Reduction: Carbon fiber’s lightweight properties help reduce overall racket weight without compromising strength. This balance results in quicker maneuverability on the court, allowing players to respond rapidly and efficiently.

-

Customization Flexibility: Advanced production techniques allow manufacturers to tailor the integrated carbon fiber layers (such as 3k, 12k, and 18k) to meet specific performance criteria. Whether it’s achieving a Diamond, Round, or Teardrop shape, carbon fiber enables superior customization in design and performance.

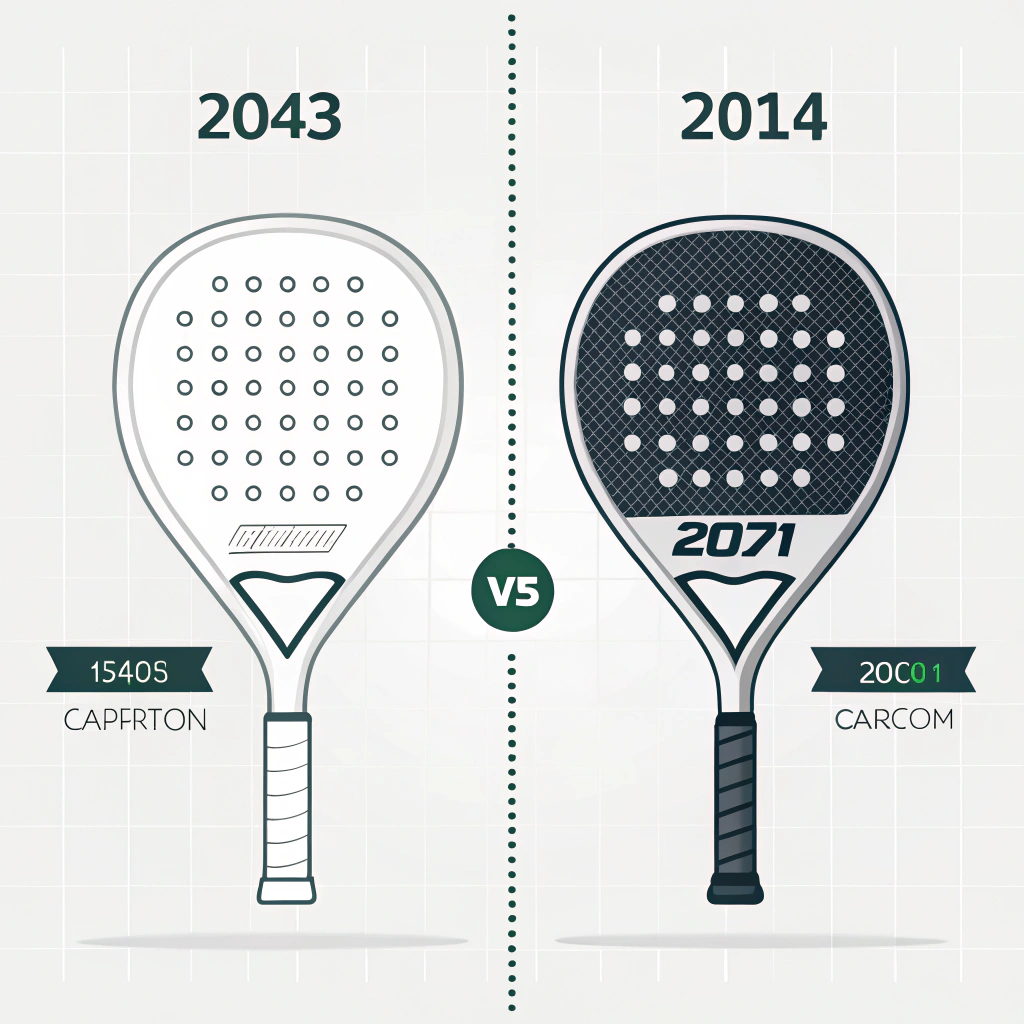

An in-depth material comparison is essential to understand how carbon fiber stands out from other materials. The table below summarizes critical technical attributes compared between traditional materials (like fiberglass) and various grades of carbon fiber:

| Material Type | Strength | Stiffness | Weight | Customization Flexibility | Typical Application |

|---|---|---|---|---|---|

| Fiberglass | Moderate | Low to moderate | Moderate | Limited | Entry-level padel rackets |

| 3k Carbon Fiber | High | High | Low | Moderate | Mid-market rackets |

| 12k & 18k Carbon Fiber | Very High | Very high | Very low | High | High-performance, premium |

In this comparison, carbon fiber—especially the higher grades like 12k and 18k—not only outperforms traditional materials in strength and stiffness but also offers substantial benefits in reducing weight. These improvements provide players with enhanced comfort, reduced fatigue, and better shot execution, which directly support the investment justification for manufacturers and distributors aiming to target the upper echelons of performance and durability standards.

Begin by defining the performance metrics critical to your brand’s value proposition. These metrics can include:

- Stiffness-to-Weight Ratio4: A higher ratio results in better energy transfer and easier maneuverability.

- Durability Metrics: Evaluate how well the material stands up to repeated impacts and high-stress play.

- Customizability: Ensure that the material supports design modifications such as shape customization, printing, and logo placement.

By setting these performance benchmarks, procurement teams can directly compare the benefits of carbon fiber with traditional alternatives.

Although carbon fiber typically commands a premium, consider the long-term benefits:

- Extended Lifecycle: The durability of carbon fiber means fewer replacements and lower maintenance costs.

- Enhanced Player Performance: Higher-quality rackets could reduce player fatigue and increase precision, leading to enhanced satisfaction and brand loyalty.

- Operational Efficiency: For manufacturers like NEX Padel, advanced production techniques using carbon fiber also streamline the production process, reducing waste and ensuring timely deliveries.

A detailed cost analysis should factor in these long-term savings. While initial costs may be high, the return on investment is realized through improved product longevity and customer satisfaction.

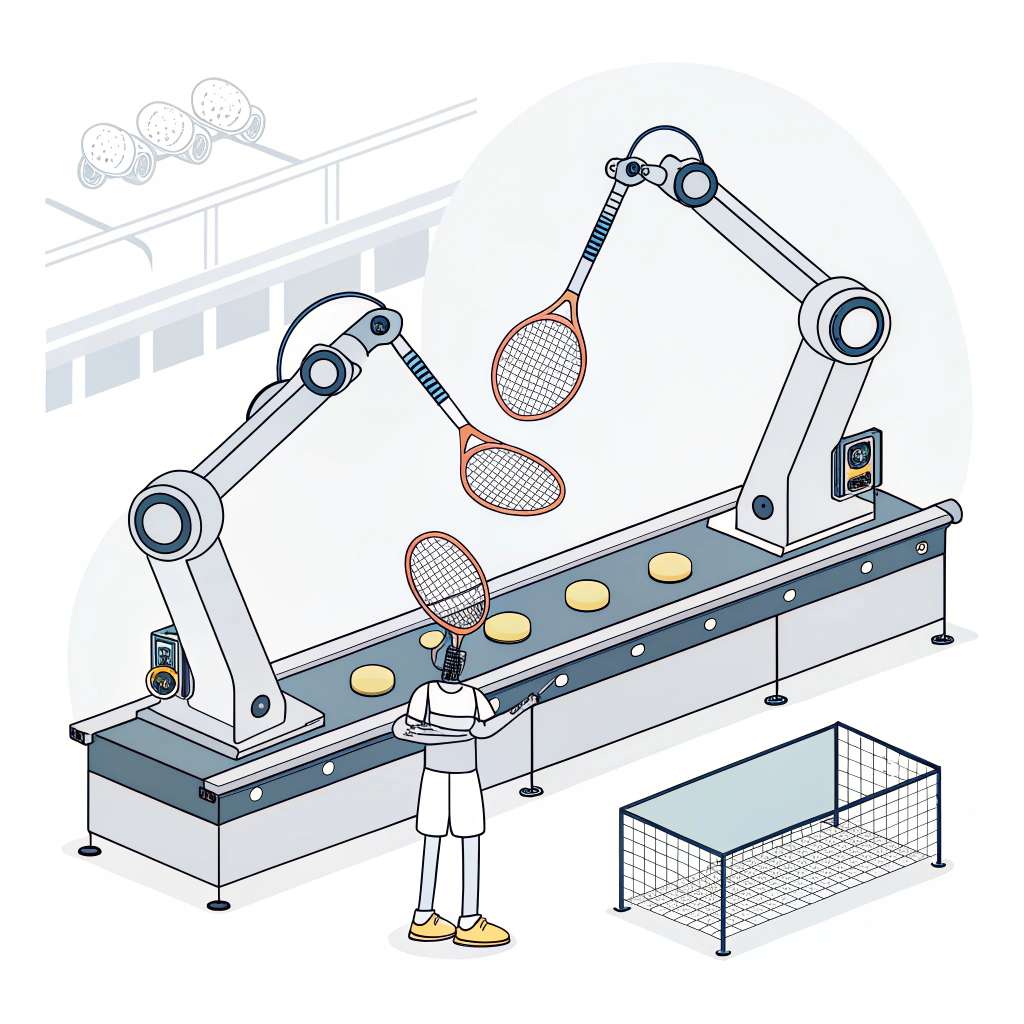

At companies such as NEX Padel, high-performance padel rackets are produced using state-of-the-art manufacturing processes. Our production line integrates various carbon fiber grades through automated layering, ensuring uniform strength across the racket’s surface. Quality control is maintained at every stage:

- Material Inspection: Pre-production testing is conducted on batches of carbon fiber to ensure consistency.

- Precision Manufacturing: Advanced machinery minimizes human error, ensuring that each racket meets strict design specifications.

- Post-Production Testing: Each finished product undergoes rigorous testing for performance metrics such as impact resistance, flexibility, and balance.

Consider a scenario where a leading distributor wanted to upgrade its product line with high-end rackets. The case study involved:

- Initial Challenge: The distributor was receiving customer feedback regarding the lack of control and durability in their mid-range rackets.

- Solution Implementation: The manufacturer transitioned from fiberglass to high-grade carbon fiber configurations, specifically using a combination of 12k and 18k fibers.

- Resulting Benefits: Not only did players report dramatically improved racket responsiveness, but the products also demonstrated a 40% increase in durability over a typical season.

This data underscores the importance of selecting the right material mix and validates the cost-benefit proposition of moving to carbon fiber.

While carbon fiber offers numerous benefits, there are important considerations to keep in mind:

- Cost Sensitivity: Higher-grade carbon fiber materials will always command premium prices. However, this should be balanced against the benefits in lifecycle and performance enhancements.

- Production Complexity: Advanced manufacturing techniques might necessitate specialized equipment and skilled labor drawn from high-tech production backgrounds.

- Market Positioning: Brands must carefully communicate the advantages of carbon fiber to their target customers, ensuring that the premium nature of the product is understood as a quality investment.

Brands should consider these limitations and apply robust quality assurance protocols to maintain consistency and reliability.

Carbon fiber integration in padel rackets is more than just a trend; it is a strategic move to upgrade performance, enhance durability, and provide customization flexibility. Here are key takeaways for procurement and product development managers:

- Invest in Quality: The performance boost offered by carbon fiber justifies the higher upfront costs when measured against long-term benefits.

- Leverage Customized Production: Advanced customization options allow you to tailor rackets to specific market needs and player preferences.

- Prioritize Long-Term Value: Improved durability and reduced maintenance costs contribute significantly to the overall return on investment.

Manufacturers like NEX Padel exemplify how precision manufacturing and rigorous quality control can transform raw carbon fiber into elite sporting equipment. For decision-makers, aligning with manufacturers who invest in advanced production processes ensures that the end product not only meets but exceeds performance benchmarks.

Taking the next step—whether it’s upgrading your supply chain or refining product specifications—will require thorough cost-benefit reviews and aligning technical specs with market demands. Evaluate your current product lineup and consider switching to high-grade carbon fiber for improved performance. In doing so, you provide athletes with the best tools while securing a competitive advantage in the market.

People Also Ask

Q: Are carbon padel rackets better?

A: Carbon padel rackets are favored in higher-end models due to their increased strength, enhanced power, and improved control. Their durability and precision make them a top choice for advanced players.

Q: Is a carbon fiber paddle worth it?

A: Yes, a carbon fiber paddle is worth the investment because it maximizes stroke efficiency and reduces fatigue. Its added stiffness allows for better responsiveness to each stroke, enhancing overall performance.

Q: What are the benefits of carbon fiber tennis rackets?

A: Carbon fiber tennis rackets offer a lightweight and strong structure, ensuring easy maneuverability and quick response times at the net. Their design promotes a head-light balance, making them suitable for players who require responsive strokes and agility on the court.

-

Carbon fiber: Reading this article provides an in-depth look at how carbon fiber’s lightweight and durable properties improve performance and longevity in sporting equipment. ^↩ ↩

-

carbon composite: Explore this topic to understand the advantages of using composite materials over traditional ones, including technical performance benefits. ^↩ ↩

-

3k, 12k, and 18k carbon fiber configurations: Learn how varying fiber grades impact strength, flexibility, and overall racket performance, helping inform your material selection process. ^↩ ↩

-

Stiffness-to-Weight Ratio: Understand why this key metric affects energy transfer and maneuverability, crucial for optimizing sports equipment performance. ^↩ ↩