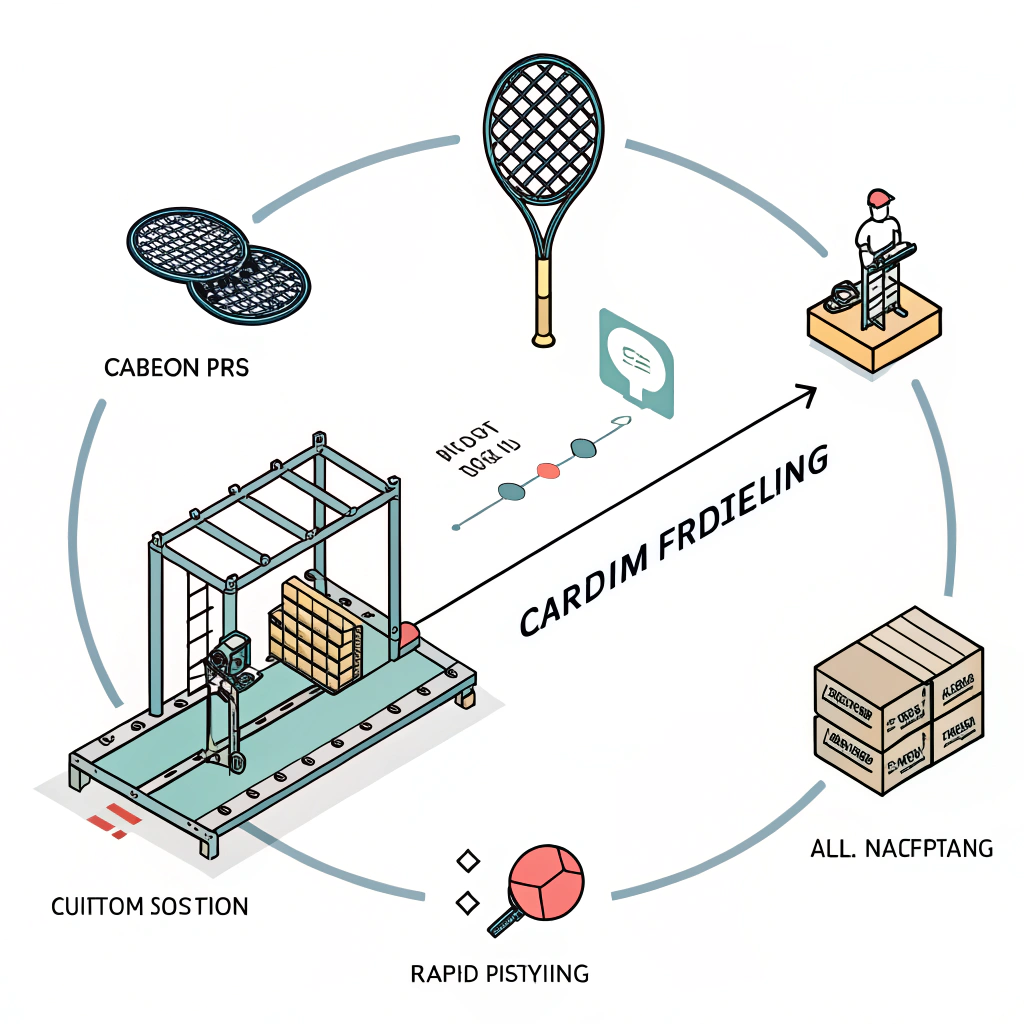

OEM padel racket manufacturers provide the optimal solution for procuring high-performance, customizable sports equipment that meets strict quality and rapid lead time requirements. This article explains how partnering with an OEM padel racket1 like NEX Padel can optimize your supply chain, improve production efficiency, and deliver superior products that meet evolving market trends.

In today’s competitive padel market, procurement managers and product development specialists need to balance quality, cost, and customization when selecting a manufacturing partner. Traditional sourcing methods can be time-consuming and may lack the consistency or flexibility required to meet high market standards. As a result, many distributors are shifting towards OEM padel racket manufacturing to leverage advanced production techniques, rapid prototyping2 and streamlined supply chain strategies.

At NEX Padel, we understand all the nuances of padel equipment manufacturing. By focusing on advanced design, material innovation, and strict quality assurance3, we empower our partners to expand their product lines with confidence. Our expertise brings significant benefits:

- Rapid prototyping and quick production cycles: Ensuring design iterations are fast and efficient.

- Customization options: From carbon fiber technologies to custom prints and colors.

- Strict quality control: Delivering a product that consistently performs under competitive conditions.

When sourcing padel rackets, production quality is paramount. At NEX Padel, our production methods combine decades of factory expertise with cutting-edge manufacturing technology. This combination is designed to support accelerated turnaround times without compromising on product durability or performance.

Our production involves multiple key technologies and material options, including:

- Carbon Fiber Options4 (3k, 12k, 18k): These variants offer different stiffness and vibration damping characteristics, catering to players of varying skill levels.

- Custom Molding: Our extensive tooling capabilities allow for three primary shapes – Diamond, Round, and Teardrop – as well as fully customized designs to match each distributor’s brand identity.

- Rapid Prototyping: Using advanced simulation software and iterative testing, we reduce lead times significantly. This means you can confidently launch new products in a competitive market window.

Quality is not just measured by product performance, but also by consistency across production batches. At NEX Padel, we implement a bimonthly quality control schedule that includes:

- Material Inspection: Every batch of carbon fiber or fiberglass is tested to ensure it meets our strict performance criteria.

- In-Process Inspection: Throughout manufacturing, adjustments are made to maintain precise dimensions and surface finishes.

- Final Product Testing: Before shipment, each racket is tested under simulated play conditions to verify durability, balance, and overall performance.

A systematic table summarizing our quality assurance process is provided below:

| Stage | Process Detail | Key Benefit |

|---|---|---|

| Material Inspection | Lab testing for consistent material quality | Ensures durability and strength |

| In-Process Inspection | On-line measurement and control | Maintains design precision |

| Final Testing | Simulated gameplay and performance evaluation | Validates real-world performance |

| Customization Checks | Verification of custom prints and shape molds | Secures brand consistency |

One of the greatest advantages of choosing an OEM manufacturer is the degree of customization available. For sports equipment distributors, having the ability to differentiate products in a crowded marketplace is crucial.

At NEX Padel, we offer extensive modification options:

- Racket Shapes: Besides our standard models (Diamond, Round, Teardrop), we also manufacture fully custom shapes based on detailed design specifications.

- Material Variability: Depending on play level and market demand, you can choose between different veil progressions in carbon fiber technology – from 3k to 18k.

- Custom Branding: Options for custom prints, colors, hand grip logos, and handle covers allow you to build strong brand identities aligned with your market positioning.

This high degree of customization is essential in a market where differentiation can drive customer loyalty. Distributors can command premium pricing when their products offer unique features such as optimized weight distribution, distinctive design elements, or improved material properties.

In the current fast-paced sports environment, production lead times can make or break market opportunities. NEX Padel invests heavily in agile manufacturing5 and process optimization, ensuring that you receive products quickly while still maintaining quality.

Key advantages include:

- Shorter Lead Times: Our rapid prototyping process and efficient production line significantly reduce turnaround times, ensuring you can stay ahead in product launches.

- Cost Efficiency: Economies of scale and precise production planning allow us to keep costs competitive, so you get high-performance equipment without inflated margins.

- Reliable Supply Chain: Partnering with a manufacturer that prioritizes supply chain reliability reduces risk and improves order fulfillment rates.

To highlight these benefits, the following table compares traditional sourcing versus OEM sourcing with NEX Padel:

| Factor | Traditional Sourcing | OEM Sourcing (NEX Padel) |

|---|---|---|

| Production Lead Time | Longer, variable | Short, reliable and consistent |

| Customization Options | Limited to standard options | Highly flexible and customizable |

| Quality Control | Often inconsistent | Rigorously standardized |

| Cost Efficiency | Potential for higher costs | Economies of scale |

| Supply Chain Management | Fragmented and unpredictable | Integrated and efficient |

For strategic decision-makers in sports equipment distribution, choosing an OEM partner is not just about obtaining a product; it’s about forging a long-term relationship that enhances competitive advantage.

- Enhanced Product Differentiation: With extensive customization options, you have the power to create truly unique padel rackets that cater to specific market needs.

- Quality Meets Efficiency: Our production process ensures that all products abide by strict quality standards while keeping the production timeline efficient.

- Streamlined Supply Chain: A reliable and agile supply chain means that your product launches can be on schedule, reducing downtime and maximizing revenue opportunities.

- Data-Driven Manufacturing: Our decisions are supported by detailed data on performance, material fatigue, and market trends to adapt quickly and efficiently to changes.

Consider a leading sports equipment distributor that was struggling to maintain consistency with traditional sourcing methods. They faced challenges such as irregular quality, longer lead times, and a lack of customization flexibility which limited their competitive edge. Switching to an OEM model with NEX Padel enabled them to:

- Reduce production lead time by up to 30%.

- Increase product customization, allowing for exclusive designs that resonated with their target market.

- Enhance overall product performance through strict quality control protocols, resulting in increased customer satisfaction and repeat business.

The combination of these improvements directly contributed to growing their market share and establishing a robust brand in the competitive world of padel sports equipment.

Before finalizing an OEM partnership, it is important to consider several factors that ensure alignment with your strategic goals:

-

Define Clear Specifications: Ensure that your technical requirements and branding elements are detailed in the initial stages to avoid surprises during production.

-

Evaluate Production Capabilities: Assess whether the manufacturer supports advanced production techniques like carbon fiber variants and rapid prototyping, crucial for innovation in sports equipment.

-

Examine Quality Assurance Processes: A robust quality control system not only guarantees superior products but also builds trust with your customer base.

-

Plan for Flexible Scalability: In an ever-changing market, scalability is key. An OEM manufacturer should offer flexibility to adjust production volume without sacrificing quality or lead times.

-

Build a Transparent Partnership: Open communication channels and regular performance reviews ensure that both parties remain aligned on expectations and delivery timelines.

By following these best practices, procurement managers and product development specialists can significantly enhance the decision-making process, ensuring that their product offerings are not only innovative but also reliable and scalable.

OEM padel racket manufacturing delivers strategic advantages that traditional sourcing methods often cannot match. By choosing an OEM partner like NEX Padel, sports equipment distributors can tap into:

- Advanced Technology and Customization: Utilizing carbon fiber techniques and rapid prototyping allows for superior product performance.

- Efficiency and Agility: Streamlined production processes reduce lead times and boost market responsiveness.

- Consistent High-Quality Outputs: Rigorous quality assurance guarantees that every product meets the high standards demanded by competitive play.

To stay ahead in the competitive padel market, take action now by engaging with an OEM manufacturer that understands both the technical and market dynamics of padel sports gear. Explore our solutions, request samples, or consult with our product development specialists to tailor your next product line. Your decision today could be the stepping stone to a more innovative and profitable product portfolio tomorrow.

Q: Do expensive padel rackets make a difference?

A: Yes, higher-priced rackets often have characteristics such as smaller sweet spots and harder construction, making them less suitable for beginners or intermediate players who benefit more from a balanced, maneuverable design.

Q: Which company makes the best padel rackets?

A: While opinions vary, leading brands include Adidas, Bullpadel, Nox, HEAD, and Babolat. At NEX Padel, our focus on advanced fabrication and customization offers competitive quality for distributors.

Q: What to look for when buying a padel racket?

A: Key characteristics include the racket's weight, balance, shape, foam hardness, materials used, and its suitability for the player's level of practice and gameplay style.

-

OEM padel racket: Click to learn about the strategic benefits and operational insights of partnering with an OEM, including production scalability, quality control, and long-term competitive advantages. ↩ ↩

-

rapid prototyping: Click to explore how rapid prototyping accelerates product development cycles and fosters innovation by enabling quick design iterations and real-world testing. ↩ ↩

-

quality assurance: Click to discover the critical processes behind quality assurance in manufacturing, ensuring consistent production standards and high product performance. ↩ ↩

-

Carbon Fiber Options: Click to understand the various carbon fiber grades available (3k, 12k, 18k), their performance characteristics, and how they impact product durability and playability. ↩ ↩

-

agile manufacturing: Click to gain insights into agile manufacturing practices that enhance production flexibility, reduce lead times, and improve responsiveness to market demands. ↩ ↩