Quick Answer: A consistent design in OEM1 padel racket production ensures high-quality, reliable performance and a strong, unified brand identity. By standardizing material specs, engineering specifications, and manufacturing processes, manufacturers can streamline operations and deliver premium products that meet both player and brand expectations.

In the fast-paced world of padel, maintaining uniformity in design is essential for ensuring both product quality and strong brand identity. For OEM brand managers and product developers, the challenge lies in balancing innovative customization with the consistent production that high-performance padel rackets require. Variations in design can lead to discrepancies in performance, reduced durability, and diminished brand recognition. Disparate design approaches may result in technical issues during production, inconsistencies in material properties, and ultimately, customer dissatisfaction.

OEM production in the padel industry involves detailed product specifications ranging from unique shapes such as Diamond, Round, and Teardrop to custom logo placements on hand grips and racket covers. As production scales, even minor inconsistencies can multiply, affecting performance and quality control. Therefore, addressing these issues early on is crucial to ensure every racket adheres to the lofty standards expected by leading brands and discerning consumers.

Understanding the source of design inconsistency is the first step toward achieving a uniform production process. There are several common causes of variability:

- Diverse Material Inputs: Rackets are produced using various high-performance materials, such as fiberglass and multiple grades of Carbon Fiber Grades (3k, 12k, 18k)2. Differences in material properties can lead to variations in racket rigidity, weight distribution, and overall feel.

- Unstandardized Production Processes: The lack of a unified manufacturing protocol can result in different assembly techniques, causing varying product outcomes even with identical design specifications.

- Communication Gaps: In projects involving multiple internal teams and external OEM partners, miscommunication or unclear design guidelines can lead to a fragmented production approach.

- **Customization vs. Standardization3: The pressure to offer customizable designs while maintaining a baseline of quality creates a complex challenge that can result in trade-offs affecting consistency.

Understanding these factors is crucial in leveraging the right solutions to enhance design uniformity throughout the production cycle.

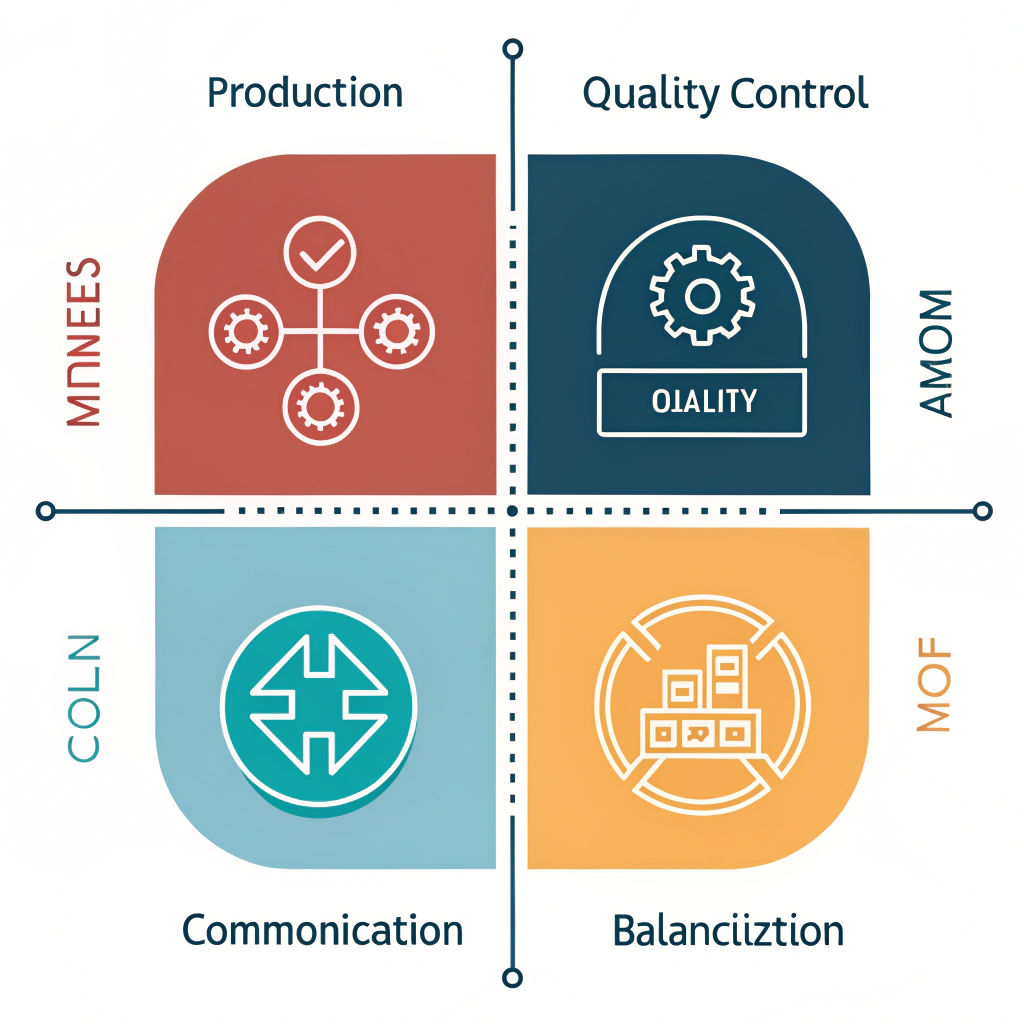

Below is an organized list of solutions designed to address these challenges and achieve consistency in OEM padel racket production:

- Solution: Develop detailed technical specifications for materials such as fiberglass and carbon fiber (3k, 12k, 18k). Implement rigorous quality control procedures to ensure that every batch meets the defined standards.

- Benefits: Consistency in material properties translates directly to uniform performance across all rackets.

- Implementation Tips: Partner with reliable suppliers and conduct regular audits.

- Solution: Establish standardized operating procedures (SOPs) for every stage of production, from design prototyping to final assembly.

- Benefits: Reduces variation in manufacturing practices, ensuring every product leaves the production line meeting the same technical criteria.

- Implementation Tips: Create detailed process documentation and train all personnel on the SOPs.

- Solution: Utilize modern communication tools and centralized project management platforms to ensure all teams—from design to production—are aligned.

- Benefits: Improved cross-departmental collaboration minimizes errors arising from miscommunication.

- Implementation Tips: Schedule regular meetings and implement a digital repository for design documents and specifications.

- Solution: While offering customization (such as unique shapes and logo placements), maintain a base design blueprint that outlines non-negotiable technical parameters.

- Benefits: Ensures that even customized products remain within a framework that guarantees performance and reliability.

- Implementation Tips: Specify core elements (e.g., frame dimensions, weight distribution) that must remain constant regardless of additional customization.

- Solution: Invest in cutting-edge manufacturing equipment and precision engineering tools.

- Benefits: Advanced production techniques ensure tighter tolerances and improved repeatability in product dimensions and performance characteristics.

- Implementation Tips: Regularly update machinery and integrate quality assurance systems that automatically check for deviations.

| Solution Element | Implementation Strategy | Key Benefit | Potential Challenge |

|---|---|---|---|

| Material Specification Standardization | Define detailed specs; use reliable suppliers | Consistent material performance | Supplier variability issues |

| Unified Production Processes | Develop and enforce SOPs; train staff | Uniform manufacturing practices | Resistance to change management |

| Enhanced Communication | Use centralized platforms; schedule frequent meetings | Reduced miscommunication errors | Integration of new tools |

| Balancing Customization and Standardization | Establish core design blueprint | Consistent performance with flexible custom elements | Maintaining creative flexibility |

| Advanced Production Technology | Invest in precision machines | High repeatability and tighter tolerances | High initial investment |

By analyzing each solution element and its impact, OEM managers and product developers can make informed decisions that foster a more consistent design process. This approach lowers production risks, enhances brand identity, and positions products more strongly in the competitive padel market.

While pursuing a consistent design strategy, several critical points and limitations must be acknowledged:

- Cost vs. Benefit Balance: Although investing in advanced machinery and quality control measures improves consistency, it often comes with significant capital expenditures. It is essential to balance these costs against potential benefits in reduced waste and increased brand reliability.

- Customization Flexibility: Some customers demand unique design elements that can contradict the goal of standardization. Finding a middle ground—where a core design is preserved while allowing for some level of customization—is vital.

- Training and Adoption: Standardized processes require comprehensive training and commitment from all involved. The success of these practices hinges on company-wide adherence and can encounter resistance if not managed transparently.

- Rapid Market Changes: The sporting goods market, particularly in padel, is dynamic. OEM companies must remain agile, adapting to emerging trends and technological advances, even while maintaining consistent design.

By understanding these limitations, companies can set realistic goals and develop contingency strategies. This balance between consistency and flexibility is the cornerstone of long-term success in a competitive industry.

A successful case study is found in companies like NEX Padel, which has consistently delivered high-performance padel rackets by focusing on standardized design across its product lines. For example:

- Design Uniformity: NEX Padel produces three types of racket shapes—Diamond, Round, and Teardrop—that all adhere to strict dimensional and material standards. This uniformity ensures that each racket, despite its unique shape, meets rigorous performance specifications.

- Material Control: By systematically managing the input materials—from fiberglass to various grades of carbon fiber—NEX Padel ensures that every product maintains the same engineering precision expected by top-tier brands such as Hirostar, Reebok, and Starvie.

- Efficient Turnaround: With a robust quality assurance program and quick sampling methods, the company achieves rapid prototyping and on-time deliveries. This efficiency in production is achieved through consistent design practices that minimize trial-and-error stages in manufacturing.

- Customization Excellence: Even when offering extensive customization options (e.g., logo placement on hand grips, unique color patterns), the foundational design remains intact, which helps in maintaining quality control and production reliability.

These examples are supported by internal data demonstrating reduced production errors and enhanced product performance when a consistent design approach is employed. Such figures are vital for OEM brand managers looking to streamline their production processes while fostering high brand identity.

Data from market surveys indicate that companies implementing standardized design protocols report up to a 30% reduction in quality control issues and a 20% improvement in customer satisfaction scores. This evidence reinforces the strategic value of adopting a consistent approach in padel racket production.

Achieving a consistent design in OEM padel racket production is not only possible but essential for maintaining quality, building brand identity, and accelerating product delivery times. By standardizing material specifications, refining production processes, improving communication, and strategically balancing customization with core design standards, OEM manufacturers can significantly enhance both product performance and market competitiveness.

Key recommendations include:

- Adopt rigorous material and process standardization protocols.

- Invest in advanced production technologies with precision engineering capabilities.

- Leverage centralized communication tools to align all production teams.

- Maintain thorough documentation and continuous training programs.

- Analyze performance data regularly to calibrate and update design standards.

For OEM brand managers and product developers in the padel industry, embracing these practices will lead to a more robust, streamlined production process. In today’s competitive market, the benefits of consistent design not only manifest in superior product performance but also build a lasting brand reputation that attracts and retains customers.

Q: How to be more consistent in padel?

A: Consistency in padel can be improved through soft, controlled shots that reduce the risk of errors like hitting the net or sending the ball long. These techniques lower risk while allowing players to manage pace and rhythm effectively.

Q: What makes a padel racket better?

A: A padel racket is considered better when it strikes a balance between weight and maneuverability. A heavier racket tends to offer more power for aggressive play, while a lighter racket provides exceptional speed and agility for defensive maneuvers.

Q: What makes padel unique?

A: Padel is unique due to its blend of athleticism, strategy, and social interaction. Its compact court size and simplified rules provide an engaging experience for both beginners and seasoned players, making the sport accessible and enjoyable for all skill levels.

-

OEM: Click to learn about the Original Equipment Manufacturer model, its role in outsourced production, and how OEM strategies drive brand collaboration and supply chain integration. ↩ ↩

-

Carbon Fiber Grades (3k, 12k, 18k): Discover the differences between various carbon fiber grades and their specific applications in high-performance products, including benefits related to strength, stiffness, and durability. ↩ ↩

-

Customization vs. Standardization: Understand the balance between offering custom designs and maintaining core standard processes to ensure both product uniqueness and reliability, crucial for competitive market success. ↩ ↩

-

Unified Production Processes: Explore how establishing standardized operating procedures (SOPs) can streamline manufacturing, improve efficiency, and ensure consistent quality in production. ↩ ↩

-

Advanced Production Technology: Learn about the latest advancements in production technology and precision engineering, and how these innovations contribute to tighter tolerances and enhanced product performance. ↩ ↩