A full-carbon padel racket uses carbon fiber in the frame and faces (3K/12K/18K), giving higher stiffness, more efficient power transfer, and greater precision than fiberglass or hybrid constructions. For advanced players, full-carbon rackets typically deliver:

- Higher torsional rigidity1 (more stable on off-center hits)

- Lower energy loss at impact (more “direct” feel and power)

- Better long-term durability and resistance to frame fatigue

However, they also transmit more vibration, demand better technique, and come at a higher cost. The best choice for your brand’s next-season line is not “full-carbon or not”, but which carbon (3K/12K/18K), which shape (Diamond/Round/Teardrop), and which EVA hardness to pair for each target player profile.

For a category manager, the migration from fiberglass/hybrid to full-carbon padel rackets is driven by three forces:

-

Player expectations at advanced level

Advanced players and coaches expect:- Consistent response across the face

- Stable behavior on fast balls and aggressive volleys

- A “connected” feel to the ball for precision and spin

These attributes correlate strongly with higher carbon content and better layup design2.

-

Performance differentials vs fiberglass / hybrids

- Fiberglass: more flexible, easier power at low swing speed, more comfort, but less precision and shorter lifespan for heavy hitters.

- Hybrid (carbon + fiberglass): balanced step-up option, good for intermediates.

- Full-carbon: higher stiffness, better control at high pace, more predictable over time.

-

Brand positioning & price architecture

Full-carbon frames justify higher RRPs and clear tiering in your catalog:- Entry: fiberglass or hybrid

- Mid: 3K carbon faces with fiberglass or mixed frame

- High/Pro: full-carbon frame + 3K/12K/18K faces, customized EVA and balance

NEX Padel sits mainly in the mid-to-high segment, offering fiberglass, 3K, 12K and 18K carbon layups with fast sampling and stable OEM capacity.

In marketing, K-count is often reduced to “higher K = more power”, but the reality is more nuanced. K describes the number of carbon filaments in each tow3 (3K = 3,000 filaments), and in practice it affects:

- Surface stiffness and response

- Impact feel and dwell time

- Weight distribution and layup possibilities

A simplified comparison:

| Carbon Type | Typical Feel | Stiffness (Face) | Power Potential | Control / Precision | Comfort | Common Use Case |

|---|---|---|---|---|---|---|

| Fiberglass | Elastic, “trampoline” | Low | Easy power at low speed | Lower at high pace | High | Entry / comfort |

| 3K Carbon | Lively but forgiving | Medium | Balanced | Good | Medium | Versatile, all-round |

| 12K Carbon | Crisp, fast response | Medium-high | High with fast swing | Very good | Medium-low | Advanced / offensive |

| 18K Carbon | Very direct, solid | High | Highest ceiling | Excellent in good hands | Lower, more demanding | Pro-level, heavy hitters |

From an OEM perspective, we usually see:

-

3K carbon:

- Ideal for advanced intermediates to advanced players looking for a mix of forgiveness and control

- Works well on Round and Teardrop shapes with medium EVA

- Good “volume seller” option in an advanced line

-

12K carbon:

- Targets players with high swing speed, needing quick ball release and stability

- Pairs well with Diamond or aggressive Teardrop shapes and medium-hard EVA

- Strong candidate for “Tour” or “Pro” sub-lines

-

18K carbon:

- Very stiff and precise, suited to top advanced or competition players

- Requires careful pairing (core hardness, frame geometry) to control vibration

- Ideal for flagship SKUs with higher price points and clear performance identity

At NEX Padel, we produce faces and frames with 3K/12K/18K and can mix them (e.g., 12K face + 3K frame) to tune stiffness and cost.

Once you decide on full-carbon, the bigger levers for feel and playability are head shape, EVA hardness, and balance point.

NEX Padel supports the three standard shapes and full custom molds:

-

Round

- Sweet spot: larger, centered

- Typical balance: more head-light to even

- Player: control-focused, defensive, consistent baseliners, many intermediates and coaches

- Best paired with: 3K carbon (or 12K for stiffer “pro control” models), soft-to-medium EVA

-

Teardrop

- Sweet spot: mid-to-upper area

- Typical balance: even to slightly head-heavy

- Player: all-round advanced, balanced power/control, attacking when possible

- Best paired with: 3K or 12K carbon, medium EVA

-

Diamond

- Sweet spot: higher up the head

- Typical balance: more head-heavy

- Player: advanced aggressive hitters, strong overhead game, smash-focused

- Best paired with: 12K or 18K carbon, medium-hard EVA

EVA hardness is as critical as carbon type. In lab and on court:

-

Soft EVA

- More dwell time → more comfort, easier depth at low speed

- Slightly less top-end control for very powerful players

- Good for: long sessions, players with arm issues, control frames targeting wider audience

-

Medium EVA

- Balanced feel → enough rebound, but still predictable at pace

- Most popular for multi-segment lines

- Safe default for 3K and 12K full-carbon designs

-

Hard EVA

- Very fast, “dry” response → maximum control for players with high swing speed

- More demanding on technique, higher vibrations

- Best when combined with Round/Teardrop shapes or vibration-damping layups

3.3 Balance and swing weight4

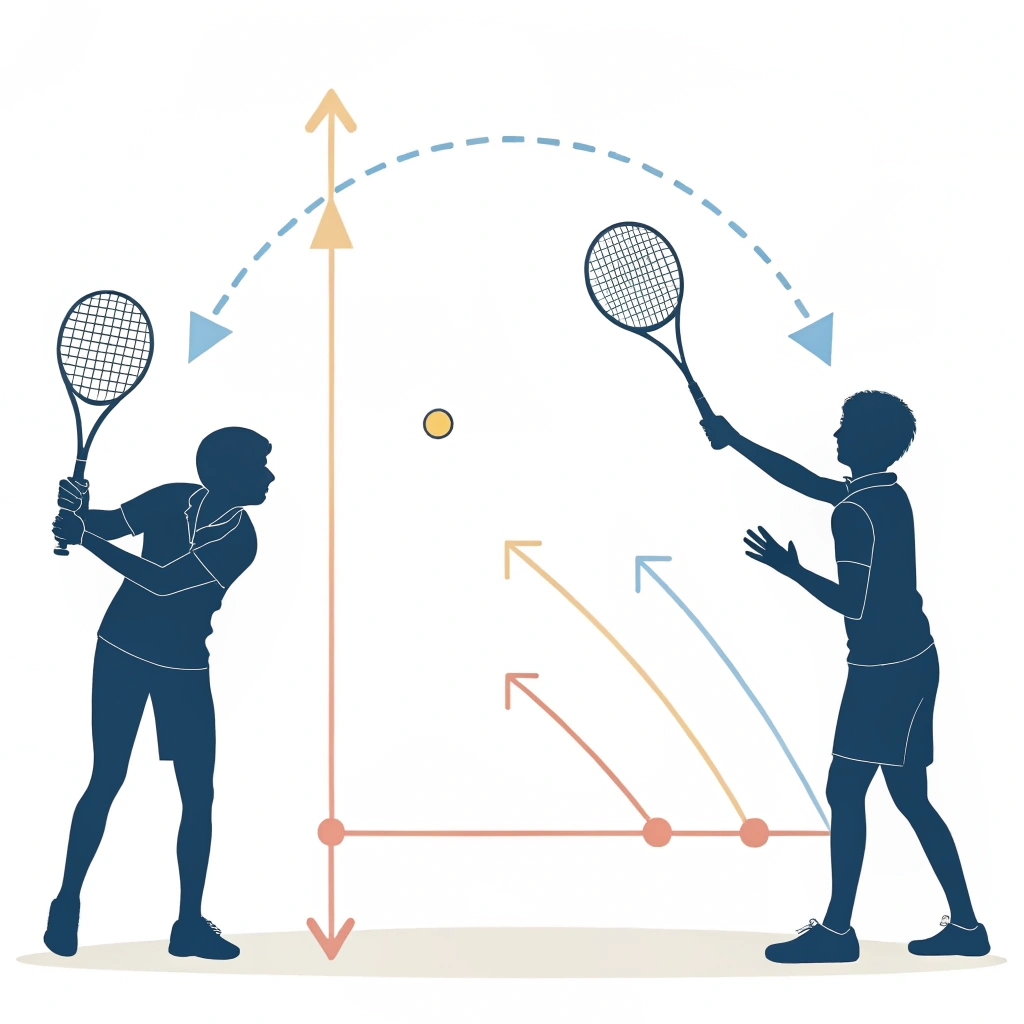

Two rackets with the same static weight can play very differently due to balance and swing weight:

-

More head-heavy (high balance point)

- Higher swing weight → more power on smashes, more inertia on volleys

- Feels “heavier” in the hand

- Common in Diamond full-carbon power frames

-

More head-light

- Lower swing weight → easier maneuverability and faster reaction at the net

- Better for quick doubles exchanges and defensive play

In OEM projects, we work with customers to set:

- Target static weight (usually 355–375 g unstrung)

- Desired balance range (e.g., 260–270 mm for control, 270–285 mm for power)

- Tolerance and QC bands to keep batch-to-batch consistency

With full-carbon you can push power and control simultaneously, but trade-offs remain:

-

More face stiffness (12K/18K, hard EVA, Diamond/head-heavy) →

- Higher top-end power if the player swings hard

- Tighter directional control

- Increased demand on technique

-

Slightly softer setups (3K, soft/medium EVA, Round/Teardrop) →

- Easier depth for a broader range of players

- Larger effective sweet spot

- Better for “all-round advanced” rather than pure elite segments

Torsional rigidity is crucial for consistent results on mis-hits, especially in doubles:

- Full-carbon frames with optimized beam geometry show less twisting on balls hit toward the edge of the face.

- This translates into:

- More predictable ball flight

- Reduced energy loss

- Better confidence near the glass and on fast returns

NEX Padel uses different frame cross-sections and layup orientations to tune torsional stability for each mold, then validates via repeated impact and lab bending tests.

Full-carbon is stiffer, so controlling vibrations is central:

- Tools we use as OEM/ODM:

- EVA hardness and density

- Layup sequence (e.g., integrating elastic layers near the core)

- Handle design and grip materials

- For advanced but not elite players, a popular recipe is:

- 3K or 12K faces

- Medium EVA core

- Slightly thicker or more damped handle

For brands wanting a “Pro, but arm-safe” model, we can co-develop hybrids: carbon faces + selective fiberglass or aramid layers to tailor damping.

Full-carbon designs have clear advantages in durability:

- Higher resistance to:

- Repeated high-impact overheads

- Minor frame collisions with glass or court

- Lower fatigue over time:

- The response of 3K/12K/18K carbon faces remains more stable after thousands of impacts

- Less “softening” or “dead” feeling compared to fiberglass-heavy layups

To keep failure rates low at OEM scale, we combine:

- Controlled resin content, curing cycles and temperature profiles

- Regular batch tests (impact cycles, static load, deformation under torque)

- Traceable production for big clients (lot-based QC reports on request)

Below is a practical assortment blueprint for a brand wanting to upgrade its advanced range with NEX Padel as OEM/ODM partner:

| Model Role | Shape | Carbon | EVA | Balance | Target Player | Positioning |

|---|---|---|---|---|---|---|

| Control Pro | Round | 3K full-carbon | Soft / Medium | Head-light to even | Advanced control players, coaches, defensive styles | “Comfort control” flagship |

| All-Round Pro | Teardrop | 3K or 12K | Medium | Even | Advanced all-rounders, league players | Volume best-seller |

| Power Pro | Diamond | 12K | Medium-hard | Head-heavy | Advanced aggressive hitters with good technique | Attack-focused hero SKU |

| Elite Power | Diamond | 18K | Hard | Head-heavy | Top competitors, strong physically, looking for max power/control | Limited “halo” product |

| Comfort Advanced | Round / Teardrop | Hybrid (Carbon + Fiberglass) | Soft | Head-light | Intermediates transitioning to full-carbon feel | Price-entry to advanced line |

NEX Padel can customize for each:

- Paint & graphics (full custom artwork, colorways, matte/gloss finishes)

- Logo on hand grip and butt cap

- Surface texture (sand, embossed pattern) for enhanced spin

For buyers comparing OEM options, the decision is not only technical but also operational.

We offer:

- Face and frame materials:

- Fiberglass

- 3K, 12K, 18K carbon (full-carbon or hybrid layups)

- Core options:

- Soft / Medium / Hard EVA with different densities

- Shapes:

- Standard Diamond, Round, Teardrop

- Fully custom molds for exclusive shapes

- Finishes:

- Smooth or rough surface for spin

- Custom color schemes, prints and logos

We can work from:

- Your existing technical spec, or

- A performance brief (“Advanced control, round, medium, 3K”) and co-design the layup.

- Sampling: fast prototyping to let your team and ambassadors test different:

- Carbon types (3K vs 12K vs 18K)

- EVA hardness

- Balances and weights

- MOQ: competitive and flexible depending on:

- Number of SKUs

- Level of customization (mold, graphics, packaging)

- Lead time: optimized production planning in Jiaxing, Zhejiang, with experience supplying well-known brands like Hirostar, Reebok, and Starvie.

We focus on:

- Consistent weight/balance tolerance per SKU

- Monitoring frame cracking and delamination5 incidents

- Supplier audits for carbon and EVA raw materials

For serious distributors and chains, we can align on target warranty return rates and jointly tune specs (e.g., slightly thicker frame, more robust bumper) for specific markets.

When you brief an OEM like NEX Padel for a full-carbon line, clarify:

Performance & player profile

- Is each SKU for control, all-round, or power?

- Target level: advanced intermediate, advanced, or elite?

- Typical player traits: heavy hitter vs touch player, arm sensitivity, match frequency.

Technical spec

- Shape: Diamond / Teardrop / Round

- Carbon: 3K, 12K, 18K, or hybrid (e.g., 12K face, 3K frame)

- EVA hardness: soft / medium / hard

- Target weight & balance: value plus tolerances

- Surface: rough / smooth, desired spin behavior

Brand and commercial

- RRP tier and competitive set (which brands/models you benchmark)

- Graphic identity, logo placements (including grip and butt cap)

- Packaging requirements (bags, hangtags, labels, barcodes)

- Expected volumes, launch timeline, key markets

Once these points are defined, sampling can move quickly and your advanced line can be locked in with fewer back-and-forth cycles.

Carbon padel rackets are generally better for advanced players because they are stiffer and more stable than fiberglass or hybrid rackets. The stiffer carbon frame and faces transfer energy more efficiently, giving more power and directional control, especially at high swing speeds. They also tend to be more durable and keep their playing characteristics longer.

However, carbon rackets feel harder and can transmit more vibration, so for beginners or very casual players, a softer fiberglass or hybrid option may be more comfortable and easier to use.

More expensive padel rackets usually use higher-grade materials (like 3K/12K/18K carbon), better cores and more advanced layups. This can give:

- More consistent performance across the face

- Better stability on fast balls

- Longer-lasting playing characteristics

That said, simply buying the most expensive racket will not automatically improve a player’s level. The biggest difference appears when a player moves from an old or basic racket to a model that matches their current level and style. For advanced players training and competing regularly, investing in a well-designed full-carbon racket can provide a real performance benefit and better durability over time.

-

Torsional rigidity: Read to learn how torsional stiffness affects off‑center stability, common test methods, and how beam geometry and layup choices improve consistency under mis-hits. ↩

-

Layup design: Explore how ply orientation, stacking sequence, weave choice, and resin content shape stiffness, feel, durability, and cost across 3K/12K/18K constructions. ↩

-

Tow: Understand filament count per tow and how it influences drape, resin uptake, surface response, and the practical differences between 3K, 12K and 18K fabrics. ↩

-

Swing weight: See how to measure and specify moment of inertia, typical padel ranges, and how balance point and mass placement impact maneuverability and power delivery. ↩

-

Delamination: Learn causes and prevention (adhesion, curing, resin control), detection in QC, and field warranty implications to reduce returns and failure rates. ↩