Padel rackets made in China offer a winning combination of cost-effectiveness, customization1, and performance. By leveraging advanced production techniques2, manufacturers like NEX Padel deliver high-performance rackets that are ideally suited for businesses seeking a reliable, efficient, and innovative supplier partner.

Many sports equipment distributors and procurement managers face the common challenge of balancing quality, production speed, and cost when sourcing new padel rackets. Particularly in this competitive sports equipment market, every business decision must carefully weigh manufacturing location, materials, customization1 options, and after-sales support.

Key challenges include:

- Maintaining competitive pricing without sacrificing quality.

- Meeting customization demands for brand differentiation.

- Ensuring a stable and efficient supply chain.

- Addressing varying performance needs of different player levels.

- Achieving rapid turnaround without compromising durability.

These challenges drive the need for manufacturers who can smartly combine technological innovation, stringent quality control, and flexible production strategies.

Advantages of Chinese manufacturing3

Chinese manufacturing, especially in the sports equipment domain, has evolved substantially over the years. Manufacturers such as NEX Padel have gained a reputation for their commitment to quality, precision, and cost management. A few core advantages include:

-

Cost-Effectiveness:

Leveraging economies of scale, Chinese manufacturers can provide competitive pricing without sacrificing the quality of the product. This is especially important for businesses looking to expand their product range while maintaining healthy profit margins. -

Advanced Production Techniques:

With the integration of state-of-the-art technology, Chinese manufacturers employ methods that ensure precision in production. Techniques such as automated molding, state-of-the-art carbon fiber processing (including 3k, 12k, and 18k carbon fiber variants), and rigorous quality assurance testing mean that every racket produced meets strict performance standards. -

Customization and Flexibility:

One of the defining features of manufacturers like NEX Padel is their ability to offer full customization1. Whether it’s adjusting the racket shape (Diamond, Round, Teardrop) or adding branded elements like custom prints, colors, logos, and accessories such as hand grips and handle covers – the flexibility is a game changer in the B2B market. -

Rapid Prototyping4 and Turnaround:

Speed is of the essence in the fast-paced business world. Chinese manufacturers invest heavily in their R&D and production processes which result in faster prototyping and rapid delivery times, enabling businesses to respond quickly to market trends. -

Quality Materials and Durability:

Materials play an important role in the performance of padel rackets. Chinese manufacturers have mastered the art of using various materials — from fiberglass for a smooth feel to advanced carbon fibers for enhanced durability and performance. Each material is carefully selected based on the intended performance and user requirements.

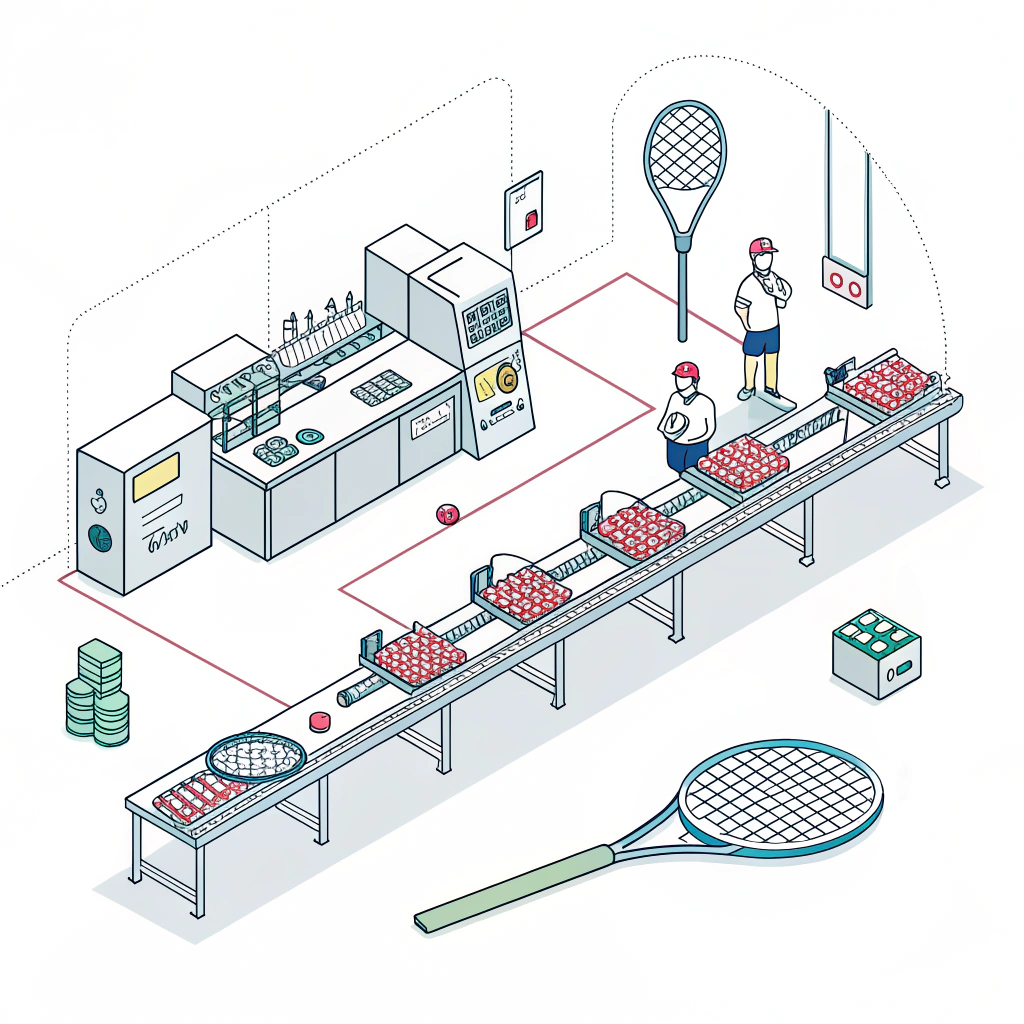

The manufacturing process is the backbone of the quality and reliability of the final product. For businesses that want to ensure their product meets customer expectations, understanding the production process is essential.

Manufacturers begin by sourcing high-quality raw materials. The selection ranges from fiberglass for players looking for ease of use, to advanced carbon fiber options for high-performance needs. Rigorous testing procedures are implemented at every stage to confirm material consistency and durability.

The shaping process is critically important. Different designs such as Diamond, Round, and Teardrop have unique production requirements. Manufacturers utilize computerized precision tools to create molds that match the exact specifications. This ensures that each racket not only meets design standards but also maximizes performance possibilities.

For B2B buyers, customization1 is key. Manufacturers like NEX Padel support extensive customization in terms of racket shape, color, prints, hand grips, and handle covers. This helps brands to follow a unique identity in the market and cater to niche customer demands. Businesses have the flexibility to incorporate specific logos or design elements that reflect their brand’s essence.

Step 4: Quality Assurance5 and Final Inspection

Before shipping, each racket undergoes multiple quality tests. These include performance testing, durability tests, and aesthetic inspections. Only the rackets that pass these rigorous checks are approved for delivery, ensuring end customers receive products they can trust.

Effective packaging and smart logistics strategies ensure that the products reach the market promptly and safely. With modern solutions like pressurized tube packaging for padel balls, manufacturers assure that both rackets and related products retain their intended performance until they reach their destination.

Below is a simplified table that compares key factors between China-based manufacturers and some other regions:

| Factor | China-Based Manufacturing | Other Regions |

|---|---|---|

| Cost-Effectiveness | Competitive pricing with economies of scale | Generally higher costs |

| Production Speed | Quick turnaround with advanced technology | Often slower due to traditional methods |

| Customization | Extensive options including shape, color, and prints | Limited customization options |

| Quality Control | Rigorous in-house testing and modern production lines | Varies significantly between manufacturers |

| Supply Chain Efficiency | Robust networks and integrated logistics solutions | Potential delays and higher transportation costs |

| Material Options | Variety from fiberglass to multiple grades of carbon fiber | Less variety in material offerings |

This table clearly shows that China-based manufacturers, like NEX Padel, offer a combination of value, innovation, and service that is difficult to match.

When sourcing padel rackets, here are some key points that B2B procurement officers should consider:

- Customization Capability: Ensure the manufacturer can meet your specific design and branding requirements.

- Production Capacity and Scalability: Check if the supplier can handle increasing order volumes as your business grows.

- Quality Assurance Programs: Inquire about the manufacturer’s quality control processes. Consistency in quality is critical, and advanced testing facilities are an essential asset.

- After-Sales Support and Communication: Effective communication, timely updates, and responsive customer service are crucial for a smooth supply chain.

- Material and Technology Expertise: Work with a supplier who offers a wide range of material options and modern production techniques that can be tailored to different player segments.

There is a prevalent belief that higher prices automatically equate to better quality in sports equipment. In the context of padel rackets, this isn’t always true. Expensive rackets often come with smaller sweet spots and increased stiffness, which might not be suitable for beginners or intermediate players. Instead, the focus should be on finding a balance between performance, durability, and cost—an area where Chinese manufacturers excel.

Recent market research shows that businesses are increasingly turning to China-based manufacturers for sports equipment. According to industry reports, nearly 40% of padel racket orders now originate from Chinese suppliers, driven by the need for innovation, production speed, and cost-efficient production methodologies. This shift not only enhances market competitiveness but also promotes a broader range of choices for sports equipment retailers and distributors worldwide.

Consider the success story of several reputed brands that turned to NEX Padel for their equipment needs. Brands such as Hirostar, Reebok, and Starvie have consistently benefited from partnering with a manufacturer that delivers:

- Fast Prototyping and Flexible Production: Rapid turnaround times mean these brands can quickly adapt to evolving market trends, launching new products without lengthy delays.

- High-Performance Products: The advanced material options (from fiberglass to multi-layer carbon fiber) ensure that the rackets meet the performance demands of both amateur and professional players.

- Customization and Branding: Whether it's custom shapes, color schemes, or personalized prints, these brands have been able to differentiate their products in a competitive market.

These success stories underscore the potential for sustained business growth when partnering with a reliable manufacturer that can deliver both quality and quantity. The ability to swiftly transition from design to production provides businesses a strategic edge that is hard to find elsewhere.

To sum up, China-based manufacturers like NEX Padel present an excellent opportunity for businesses involved in sports equipment distribution. The key benefits include:

- Cost-effective solutions without quality compromises.

- Advanced production techniques and material expertise.

- Flexible and customizable manufacturing that meets the diverse needs of global markets.

- Stringent quality control and supply chain efficiencies that ensure product reliability.

- Proven track record of delivering rapid prototyping, quick turnaround times, and after-sales support.

For any business looking to expand its padel racket lineup with options that combine performance, durability, and customization, partnering with a China-based supplier can be the ideal strategic move. With trends favoring speed and customization in product development, now is the perfect time to evaluate and select a manufacturer aligned with your business objectives.

-

Which company makes the best padel rackets?

Major brands such as Adidas, Bullpadel, Nox, HEAD, and Babolat are well-recognized. However, many businesses also consider manufacturers like NEX Padel due to their custom solutions and advanced production capabilities. -

Do expensive padel rackets make a difference?

Not necessarily. Expensive rackets are often designed with smaller sweet spots and greater stiffness, which might not be ideal for beginner or intermediate players. The performance of a racket depends on its build and design rather than its price alone. -

What are the best padel rackets made of?

The best material depends on the player’s needs. Fiberglass offers comfort and ease of use, while various grades of carbon fiber (such as 3k, 12k, and 18k) deliver high durability and strength, making them suitable for advanced players.

-

Customization: Reading this article will provide an understanding of how tailored production processes enable brands to differentiate themselves in competitive markets. ↩ ↩2 ↩3 ↩4

-

Advanced production techniques: Reading this article will offer insights into state-of-the-art technological methods used to ensure precision and quality in manufacturing. ↩

-

Chinese manufacturing: Reading this article will help you understand the unique advantages and strategies behind leveraging China's production ecosystem in sports equipment. ↩

-

Rapid Prototyping: Reading this article will explain how accelerated development processes empower businesses to quickly adapt to changing market trends. ↩

-

Quality Assurance: Reading this article will highlight the rigorous testing and inspection protocols that guarantee product reliability and performance. ↩