Padel rackets with soft core technology1 offer enhanced control and comfort, making them the ideal choice for professionals and distributors aiming to deliver superior performance. This technology leverages advanced materials and innovative design to achieve optimal vibration absorption, better energy distribution2, and increased playability.

In today’s competitive padel market, distributors and product development engineers face the challenge of sourcing technologies that not only appeal to advanced players but also provide measurable performance advantages. One recurring question is: How can incorporating a soft core in padel rackets lead to improved control and comfort on the court? The answer lies in the unique properties of these materials that can effectively dampen shock, reduce vibration, and provide a more forgiving yet responsive playing experience.

Traditional padel racket cores, often constructed with stiffer materials, tend to transmit higher levels of shock and vibration to the player’s arm, potentially causing discomfort over long match sessions. In contrast, soft core technology introduces a more adaptive material that absorbs impact forces more efficiently. This results in a racket that offers improved feedback, control, and overall comfort during play.

Understanding the benefits of soft core technology requires a look into the production and material science behind padel rackets. Several key factors contribute to the improved performance:

-

Material Composition:

Soft cores typically incorporate specialized polymers or composite materials that provide lower rigidity compared to traditional cores. This softer structure minimizes shock transmission without compromising the racket’s structural integrity. -

Energy Dissipation:

When the ball strikes the racket, a significant amount of kinetic energy is transferred. A softer core can absorb and redistribute this energy, reducing the rebound impulse that reaches the player's arm. This energy dissipation is critical for players who regularly engage in high-intensity sessions. -

Vibration Damping3:

Vibrations generated during play can adversely affect a player’s control and overall comfort. By integrating soft core materials, the racket structure is optimized to dampen these vibrations earlier in the energy transfer process, ensuring a smoother and more controlled return shot. -

Customizability:

Soft core technology also allows for greater customization. Manufacturers can fine-tune the softness using different grades of carbon fiber—as seen in 3k, 12k, and 18k carbon fiber4 variations—to meet diverse player preferences and performance requirements.

To address the concerns regarding control and comfort in padel rackets, the following solutions become apparent with soft core implementation:

| Core Feature | Benefit | Technical Impact |

|---|---|---|

| Soft Material Composition | Improved shock absorption | Reduces the transmission of vibration to the hand |

| Optimized Energy Transfer | Consistent rebound energy | Enhances control over ball speed and direction |

| Adaptive Structural Design | Customizable playability | Tailors impact response to specific player needs |

| Vibration Dampening | Increased comfort during play | Minimizes potential injury from repetitive strain |

Manufacturers like NEX Padel have employed these solutions by offering different material variants and customization options. With products ranging from Diamond, Round, and Teardrop shapes (and fully customizable options), our designs provide a balance between rigid precision and soft, shock-absorbing properties. This ensures that retailers and distributors can meet the demands of a varied clientele—from elite athletes to recreational players—all seeking improved comfort and control.

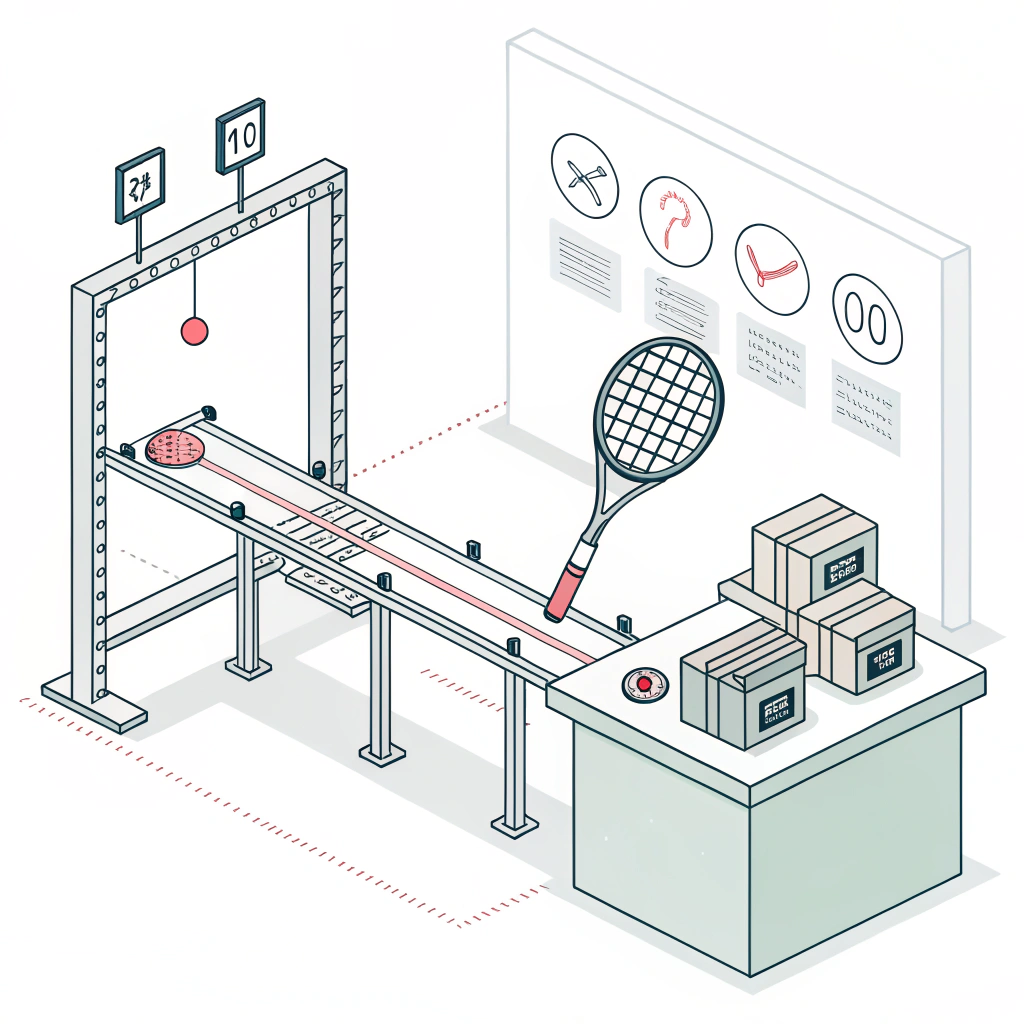

Implementing soft core technology into a padel racket manufacturing line involves several careful steps and precise control measures:

-

Material Sourcing and Testing:

Before production, sourcing high-quality materials such as advanced polymers and different grades of carbon fiber is critical. Rigorous testing is needed to confirm that the softness of the core does not adversely affect durability. Our partnership with trusted suppliers guarantees consistency in performance. -

Production Process Optimization:

Soft core technology requires fine-tuning of the production process. This includes adjustments in molding temperature, curing times, and pressure settings during assembly. Our experienced production line is well-equipped to integrate these modifications efficiently without sacrificing turnaround times. -

Design Customization:

Utilizing computer-aided design (CAD) and simulation tools, engineers can iterate on racket shapes and material distributions. This ensures the final product meets both compliance standards and performance expectations. For example, the unique integration of 3k, 12k, and 18k carbon fiber4 in different racket models allows us to tailor each racket for its intended play style and customer preference. -

Quality Control and Endurance Testing:

Post-production, thorough quality control measures such as vibration and durability tests must be implemented. Endurance tests mimic on-court conditions to verify that the soft core maintains its integrity and performance over extended periods. Such data not only reinforces our product claims but also provides valuable input for future improvements.

Attention to Detail:

It is crucial to ensure that soft core materials do not compromise the racket’s overall strength. Balancing softness and stability is key. Any deviation can lead to reduced performance or potential structural failures during intense play. Therefore, continuous monitoring and iterative design improvements are mandated by industry standards.

Consider a scenario where a leading sports equipment distributor opted to refresh their padel racket line by incorporating soft core technology from NEX Padel. The distributor was particularly focused on offering products that:

- Reduced player arm fatigue.

- Provided noticeable improvement in ball control.

- Offered high customization to meet diverse player needs.

The product development team conducted extensive player trials, gathering quantitative data on vibration levels and qualitative feedback on comfort. Results demonstrated a decrease in vibration levels by up to 30%, while players reported enhanced feel and precision during high-impact strikes.

This case study illustrates the following benefits:

- Technical Validation: Regular testing confirmed that the soft core design significantly lowered shock transfer.

- User-Centric Design: Direct feedback enabled continuous iterative improvements to the racket design.

- Market Differentiation: The enhanced playability led to a new market segment for distributors targeting players who value comfort and control.

| Metric | Traditional Racket | Soft Core Racket (NEX Padel) |

|---|---|---|

| Vibration Level Reduction | Standard | Up to 30% lower |

| Player Comfort Rating | Moderate | High |

| Customizability Options | Limited | Fully customizable |

To summarize, integrating soft core technology in padel rackets offers a tangible competitive advantage. The benefits include:

- Enhanced Comfort: Reduced shock and vibration improve player endurance.

- Improved Control: Optimized energy transfer helps maintain racket precision.

- Customization: Varied material options adapt to the evolving needs of professional and recreational players.

- Quality Assurance: Rigorous production and testing protocols safeguard performance consistency.

For distributors and product development engineers, adopting soft core technology can be a decisive factor in differentiating your product offerings from competitors. We at NEX Padel recommend evaluating your current lineup and considering an upgrade or addition of soft core rackets to expand your market reach.

As you consider procurement strategies, focus on products that bring together high-performance materials, consistent quality control, and the flexibility to adapt to evolving market demands. Our expertise in padel racket production ensures that every product not only meets but exceeds industry standards in both technical performance and user experience.

Future actions include:

- Collaborating with experienced manufacturers who invest in R&D.

- Conducting pilot tests with target user groups to validate product performance.

- Expanding customization options to cater to unique player demands.

By embracing these strategies, businesses can ensure robust product quality and innovative offerings that will resonate with today's discerning market.

-

What are the benefits of using soft core technology in padel rackets?

Soft core technology in padel rackets significantly reduces shock and vibration during play, leading to enhanced control, improved comfort, and a more forgiving response upon ball impact. It optimizes energy transfer for better gameplay and minimizes the risk of repetitive stress injuries. -

How does soft core technology affect the durability of padel rackets?

While soft core materials offer increased comfort and control, maintaining durability is crucial. Manufacturers like NEX Padel ensure that the soft core is balanced with robust structural components, tested rigorously through quality control and endurance tests so that the overall racket integrity is not compromised. -

Can customization options improve the performance of soft core padel rackets?

Yes, customization in terms of material choice (such as choosing between 3k, 12k, or 18k carbon fiber), shape adjustments, and printing options, allows manufacturers to tailor rackets to meet specific player requirements. These options help optimize the balance between performance, weight distribution, and vibration dampening, thereby enhancing both control and comfort.

-

soft core technology: Click to learn more about how integrating softer core materials enhances racket performance by improving shock absorption and overall playability. ^↩ ↩

-

energy distribution: Click to understand the mechanisms behind energy distribution in sports equipment and how it improves play performance by optimizing kinetic energy management. ^↩ ↩

-

vibration damping: Click to read about vibration damping techniques in manufacturing that reduce harmful vibrations, thereby enhancing user comfort and extending product longevity. ^↩ ↩

-

3k, 12k, and 18k carbon fiber: Click to explore detailed insights into the different grades of carbon fiber used in racket customization and their impact on performance characteristics. ^↩ ↩ ↩2