Customized padel rackets drive market differentiation by combining advanced materials, tailor-made design, and proven production efficiency1, ensuring your brand stands out in a competitive landscape.

For sporting goods retailers and distributors, elevating brand identity is critical. Amid a competitive padel market, it is not enough to simply stock generic sports equipment. Today’s customers demand equipment that reflects performance, style, and quality. However, achieving such differentiation can be challenging. Key issues include:

• Balancing costs with high-quality production

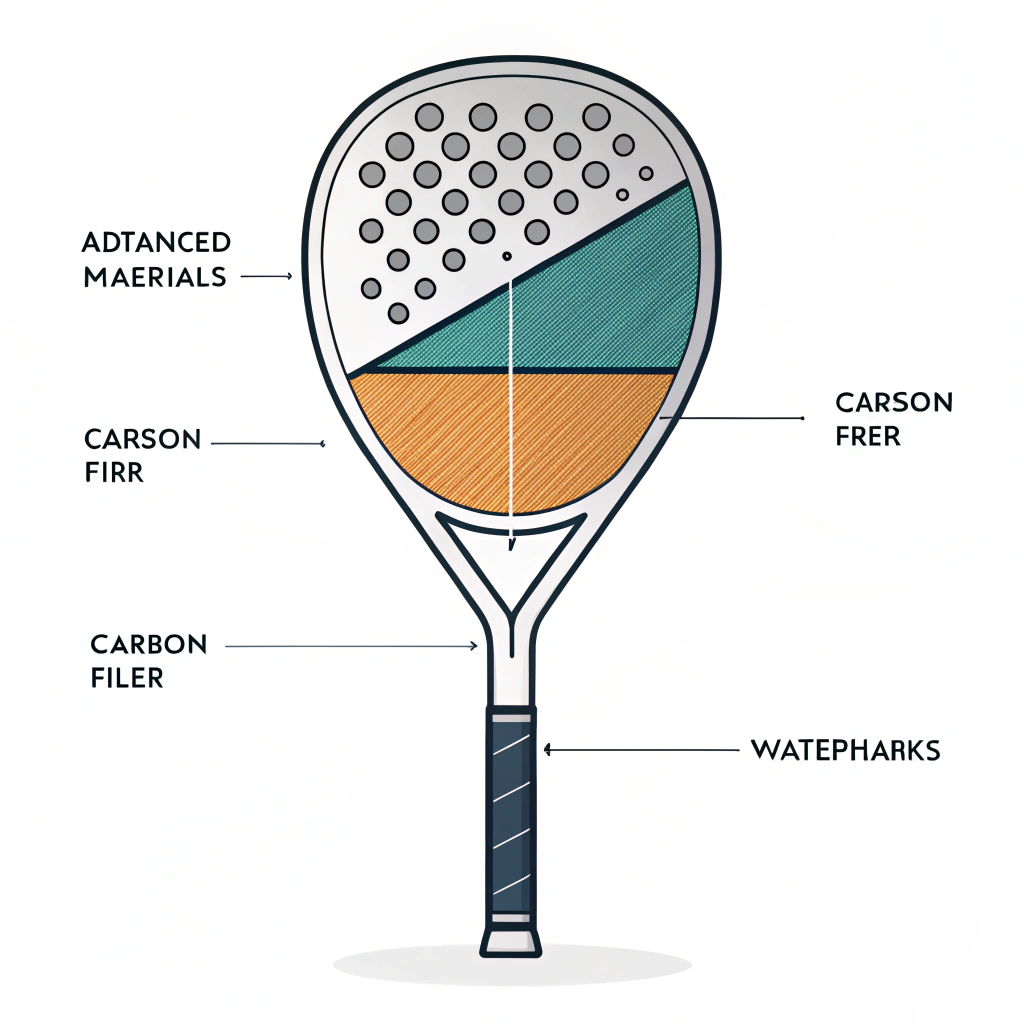

• Integrating advanced materials like carbon fiber2 and glass fiber3

• Offering flexible customization without sacrificing production efficiency

• Ensuring a reliable supply chain4 in a fast-paced market

Retail buyers and product managers thus need solutions that address these challenges holistically. With these concerns in mind, manufacturers like NEX Padel have formulated tailored approaches to offer OEM padel rackets5 that not only match evolving consumer trends but also provide a competitive edge.

In the current sporting goods industry, several market dynamics have led to the need for customized padel rackets:

- Evolving Consumer Expectations: Consumers increasingly seek equipment that conveys a sense of personal style and performance reliability. Customized designs and materials such as advanced carbon fiber2 variants cater to these expectations.

- Competitive Pressures: With numerous brands competing for the same market share, retail differentiation becomes paramount. A distinct product offering can translate into higher margins and long-term customer loyalty.

- Technological Advances: The integration of 3k, 12k, and 18k carbon fiber materials has revolutionized padel racket design. These materials not only enhance performance but also allow for innovative design elements that can be fully customized, from shape to color and additional branding on hand grips.

Understanding these underlying factors is essential for making informed decisions. It also underscores the importance of partnering with a manufacturer that can deliver customized, high-performance padel rackets.

To meet industry demands, a multi-step strategy is required. Below is a detailed solution framework that addresses the key challenges:

Manufacturers now offer a range of materials to meet different performance and price points. Options include:

- Glass Fiber: Provides optimal balance for entry-level rackets with cost efficiency.

- Carbon Fiber (3k, 12k, 18k): Offers varying levels of stiffness, durability, and performance, catering to mid-range and high-end applications.

By selecting the appropriate material, brands can tailor performance attributes to target specific market segments.

Customization isn’t limited to the materials. It extends to many design aspects:

- Racket Shapes: NEX Padel supports Diamond, Round, and Teardrop designs, along with fully custom shapes.

- Custom Printing and Colors: This enables brands to infuse their identity through unique color schemes and prints.

- Additional Customization: Customization extends to hand grips and handle covers, where logos and other personalized designs can be included.

These options enable retailers to position their products uniquely on the shelf, addressing local market preferences and trends.

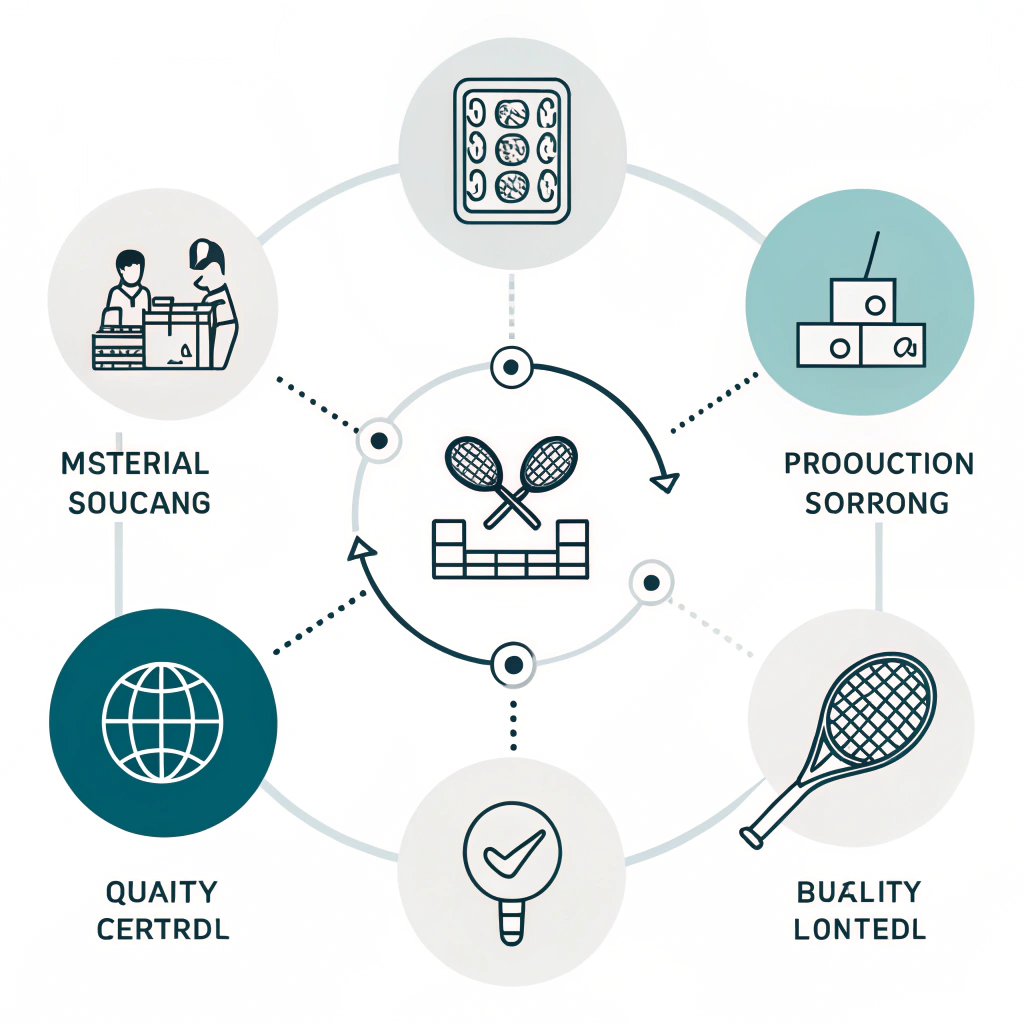

Efficiency is key to maintaining a competitive edge in fast-paced markets. Several protocols ensure both speed and quality in production:

| Production Phase | Key Focus Area | Benefits |

|---|---|---|

| Material Sourcing | High-quality carbon, glass fibers | Ensures durability and performance |

| Design & Sampling | Rapid prototyping and design verification | Shortens time-to-market |

| Production | Advanced production techniques | Consistent quality across every batch |

| Quality Control | Rigorous end-of-line testing | Reduces defects and builds customer trust |

| Logistics & Delivery | Timely and efficient distribution | Maintains supply chain reliability |

This table illustrates the robust process flow that helps mitigate risks while ensuring that every product meets high-performance standards.

Choosing the right manufacturing partner is critical. NEX Padel not only delivers high-performance padel rackets but also provides comprehensive OEM support and customization capabilities. This partnership approach ensures that:

- Retailers receive products that meet precise market needs.

- Production schedules remain on track even during peak demand.

- End consumers enjoy products that deliver on performance and style.

Distributors and procurement specialists benefit from a partner that has a proven track record, as seen in long-standing collaborations with brands like Hirostar, Reebok, and Starvie.

Industries that adopt customized padel equipment have observed a significant boost in brand perception and customer retention. For instance:

- A leading sports retailer reported a 20% increase in repeat sales after introducing a customized racket line that incorporated advanced carbon fiber technology and unique branding.

- Another distributor noted that offering three design options (Diamond, Round, Teardrop) allowed them to tailor their product line across different consumer segments, thereby driving higher overall margins.

Furthermore, market research indicates that products with higher customization options tend to command premium pricing and foster greater customer loyalty in niche markets. This underscores the practical benefits of integrating tailored design and production strategies into your product mix.

While customization brings distinct advantages, there are important considerations to keep in mind:

-

Balancing Cost and Quality:

- Customization can sometimes raise production costs. However, by leveraging efficient OEM processes and high-quality materials, manufacturers can offset these costs. It is essential to analyze the return on investment in terms of brand differentiation and premium pricing opportunities.

-

Supply Chain Reliability:

- Even the best designs and materials are only as good as the supply chain that delivers them on time. Ensuring that your manufacturing partner has robust logistics and quality control protocols is critical to avoid delays and maintain market momentum.

-

Market Trends Analysis:

- Consumer trends in sports are dynamic. Regular market research is vital to stay ahead and update product offerings accordingly. This includes understanding not just the aesthetic preferences but also performance expectations across different segments.

-

Customization Flexibility:

- Offering a range of options—from material choices to design customization—requires a flexible production system. It is important to select a partner that can quickly adapt to new design trends and evolving market demands.

For businesses looking to innovate, these operational insights translate directly into strategic benefits. By implementing best practices in customization and manufacturing, retailers can build a resilient product portfolio that resonates with informed consumers.

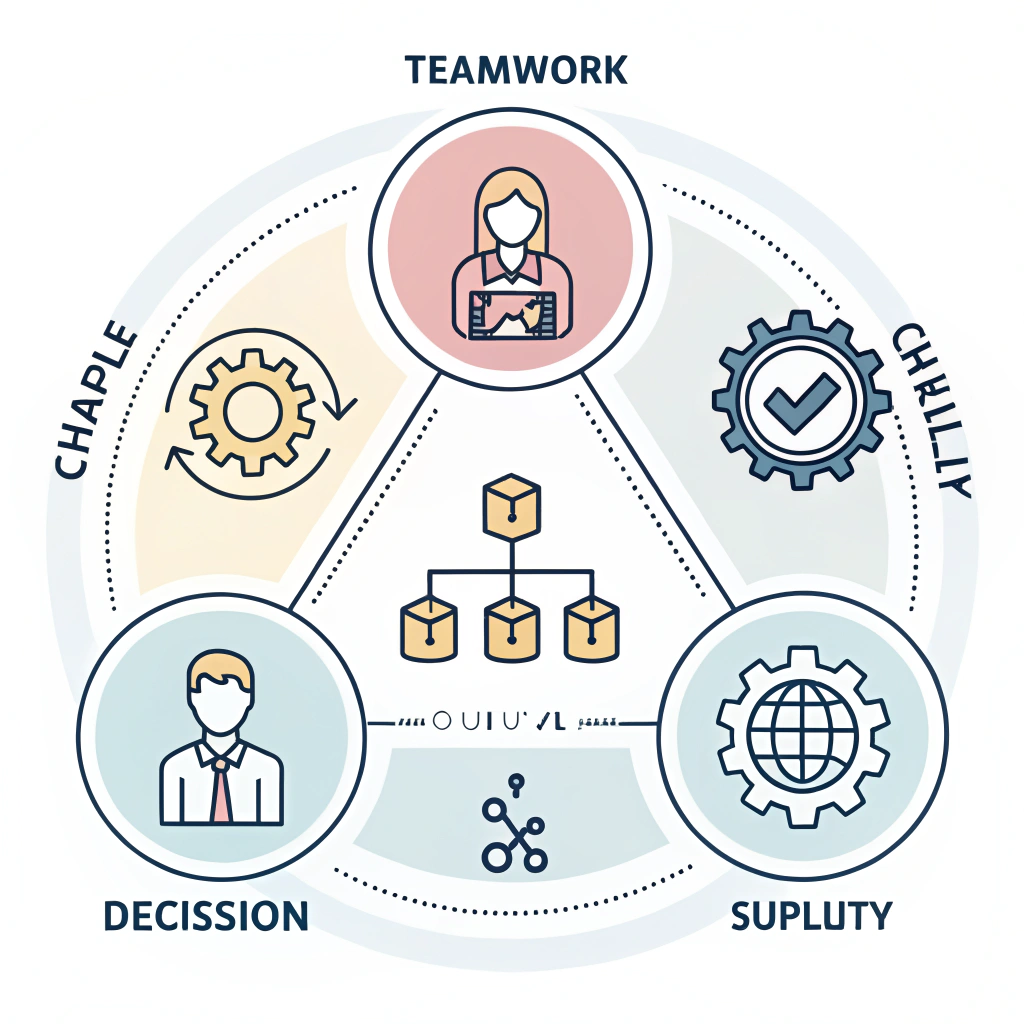

When considering a manufacturing partner for customized padel rackets, decision-makers should evaluate the following aspects:

-

Technical Capabilities:

- Does the manufacturer offer advanced materials like 3k, 12k, and 18k carbon fiber2?

- Are there options for full product customization, including shape, design, and additional elements such as hand grips?

-

Production Efficiency:

- Can the manufacturer deliver prototypes quickly?

- What quality assurance practices are in place to ensure consistency and performance?

-

OEM and Customization Expertise:

- Does the partner have experience supporting major brands such as Reebok or Starvie?

- How adaptable is their production process to meet evolving market demands?

-

Supply Chain and Delivery Reliability:

- How is the global logistics structure managed?

- Are there contingency plans to handle supply chain disruptions?

A comprehensive evaluation based on these criteria ensures that you partner with a manufacturer who not only meets technical and aesthetic demands but also underscores your brand’s strategic goals in a competitive market.

Customized padel rackets offer a clear pathway to market differentiation. By leveraging advanced materials, flexible design capabilities, and robust production processes, manufacturers like NEX Padel empower retailers to capture consumer attention and drive sales. With production efficiencies that balance cost and performance, these rackets are designed to support premium retail strategies while enhancing brand identity.

For B2B decision-makers, the key takeaway is to closely examine your production and supply chain partnerships. Prioritizing innovation, quality, and reliability in your padel equipment offerings can translate into tangible market advantages. Engage with manufacturers who not only understand the technical nuances of padel racket design but also share a commitment to delivering excellence and innovation in every product.

Take the next step to elevate your product portfolio—reach out to us at NEX Padel to discuss how our customization options and OEM expertise can align with your business goals. Together, we can build a winning strategy that captures market share in the dynamic padel industry.

• What customization options are available for padel rackets?

Manufacturers typically offer a range of customization options including different materials (glass fiber, various grades of carbon fiber), shape variations (Diamond, Round, Teardrop), and personalized branding options such as custom printing, colors, and logo placements on hand grips and racket frames.

• How does carbon fiber improve performance in padel rackets?

Carbon fiber, available in 3k, 12k, and 18k grades, significantly enhances racket performance by reducing weight and increasing structural stiffness. This results in improved power, control, and durability, making it a preferred choice for high-performance padel rackets.

• What are the benefits of OEM padel racket manufacturing?

OEM manufacturing offers benefits such as consistent product quality, production efficiency, and the ability to customize products to meet specific brand needs. It creates opportunities for differentiation in the market, helping retail buyers offer unique products that appeal to discerning consumers.

-

Production Efficiency: Click to discover techniques and technologies that enhance production efficiency, ensuring high-quality output and faster time-to-market. ↩ ↩

-

Carbon Fiber: Click to learn about the properties and advantages of carbon fiber materials, including their impact on racket performance and durability. ↩ ↩ ↩2 ↩3

-

Glass Fiber: Click to explore how glass fiber is used in sporting goods manufacturing to balance cost and performance, providing an entry-level material option. ↩ ↩

-

Supply Chain: Click to gain insights into effective supply chain management strategies that ensure product availability and timely delivery in competitive markets. ↩ ↩

-

OEM Padel Rackets: Click to understand the role of Original Equipment Manufacturer (OEM) partnerships in customizing high-performance padel rackets to meet specific brand requirements. ↩ ↩