The padel racket market is booming due to rapid industry trends, advanced manufacturing innovation1, and growing demand for customization, making it an attractive opportunity for B2B procurement managers seeking long-term competitive advantages.

In recent years, the padel industry growth has been nothing short of remarkable. This trend is driven by a combination of increased global participation, the appeal of an accessible yet technically demanding sport, and a shift in consumer preferences toward high-performance and bespoke products. With more players entering the sport, there is a significant demand for quality padel rackets that can deliver enhanced performance and durability.

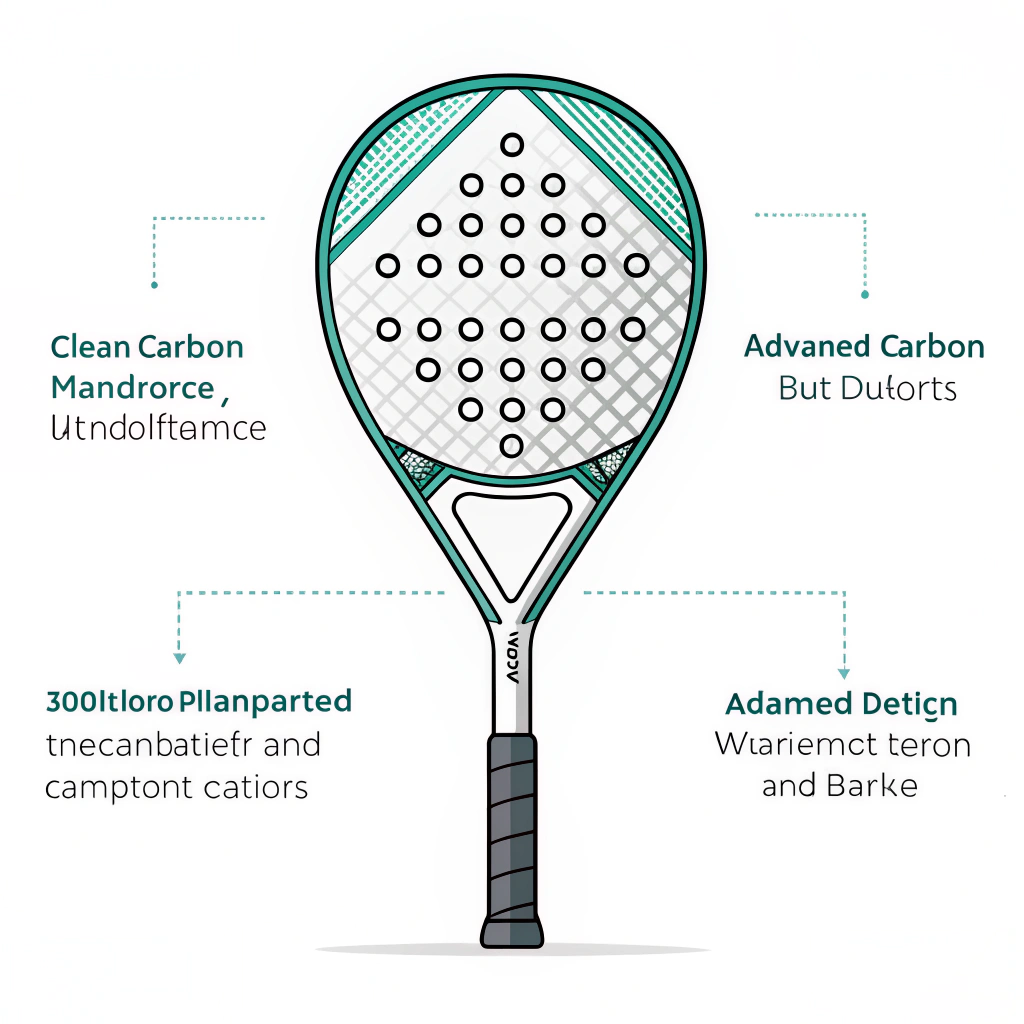

Manufacturers like NEX Padel have seized this opportunity by investing in advanced production techniques and innovative materials. Our expertise in using a variety of carbon fiber2 types—including 3k, 12k, and 18k—has allowed us to meet diverse customer needs ranging from recreational players to elite professionals. Moreover, with our capability to produce different shapes like Diamond, Round, and Teardrop (as well as fully customizable shapes), we provide B2B partners with products that stand out in both performance and aesthetic appeal.

A deep dive into the market trends reveals several driving factors:

-

Global Participation and Emerging Markets

Padel’s universal appeal has led sports clubs and distributors worldwide to invest in the sport. The low barrier of entry—in terms of equipment and field requirements—has contributed to its rapid expansion. This trend is evident in the increasing number of countries adopting padel as a mainstream sport. -

Technological and Manufacturing Advancements

Innovations in production techniques have allowed manufacturers to produce high-performance rackets consistently. The advances in carbon fiber technology, for instance, have resulted in lighter, more durable, and highly responsive rackets. These technical breakthroughs not only enhance player performance but also add value to OEM partnerships. -

Customization and Branding Trends

Custom padel rackets3 have become a key differentiator in the competitive sports equipment market. Brands and distributors are looking for products that they can personalize—whether through unique shapes, colors, or custom logos on hand grips and hand covers. This trend towards personalization offers both aesthetic and performance benefits, driving further demand. -

Supply Chain Efficiency and Quick Turnaround

Rapid prototyping and efficient logistics have become essential in today’s fast-paced market. Manufacturers who can offer quick sample production and timely deliveries, like NEX Padel, are preferred partners. The ability to quickly adapt to market changes and incorporate customer feedback is a critical success factor in this industry.

At NEX Padel, we are committed to pushing the boundaries of manufacturing processes. Our advanced production methods, coupled with our detailed quality assurance protocols, ensure that every padel racket meets the highest performance standards. Let’s look at some technical insights into our manufacturing processes:

We employ three main types of carbon fiber in our rackets—3k, 12k, and 18k. Each type has unique properties tailored for different performance needs:

| Carbon Fiber Type | Characteristics | Ideal For |

|---|---|---|

| 3k Carbon Fiber | Lightweight, excellent vibration dampening | Entry-level to intermediate rackets |

| 12k Carbon Fiber | Balanced strength and flexibility | Advanced players seeking performance and durability |

| 18k Carbon Fiber | High rigidity, superior strength, and durability | High-performance rackets for competitive play |

The precise control in layering and resin application means that every racket, whether in Diamond, Round, or Teardrop shape, can be optimized for weight distribution and balance. This becomes particularly crucial for professional players who demand consistent performance in every swing.

The ability to provide custom padel rackets3 is a game-changer in the B2B procurement landscape. Beyond the standard shapes, our facility supports:

- Tailored racket shapes for personal or brand identity.

- Custom printing options to include unique color combinations and logos.

- Personalized components such as hand grips and hand covers, ensuring the final product resonates with the brand identity of our OEM partners.

These customization options are not only about aesthetics—they also allow for performance tuning in terms of balance, weight distribution, and grip comfort, which are crucial factors in the competitive sports market.

The customization process begins with a thorough consultation with our partners, where we evaluate their market needs and performance expectations. This is then followed by a rapid prototyping4 phase—thanks to our agile manufacturing techniques—which ensures that design changes can be implemented swiftly without compromising on quality or deadlines.

Customization offers a strategic advantage for distributors looking for unique selling propositions in a crowded market. B2B buyers are increasingly looking for solutions that differentiate their product lines. With the capability to tailor every aspect of the product from the shape (Diamond, Round, Teardrop, or fully custom) to the specific carbon fiber composition, manufacturers provide an unmatched level of product differentiation.

For example, pairing a Teardrop shape with high-density 18k carbon fiber creates a racket ideal for aggressive play, while a Round shape with a mix of 3k and 12k fibers might suit players looking for control and precision. This flexibility allows our partners to target specific segments of the market while ensuring that production remains efficient and scalable.

The customization process begins with a thorough consultation with our partners, where we evaluate their market needs and performance expectations. This is then followed by a rapid prototyping phase—thanks to our agile manufacturing techniques—which ensures that design changes can be implemented swiftly without compromising on quality or deadlines.

Many leading sports brands have benefited from partnering with advanced manufacturers like NEX Padel. These partnerships are built on a foundation of reliability, performance, and innovation. Let’s consider a few key examples and data points:

-

Hirostar Collaboration: By leveraging our state-of-the-art carbon fiber manufacturing techniques, Hirostar was able to launch a new product line that captured market share through superior performance and durability. The collaboration enabled rapid prototyping and quick market entry, meeting the fast-paced demands of the industry.

-

Reebok Partnership: Reebok sought a bespoke solution that aligned with their branding strategy, opting for customized padel rackets that could be personalized for their target demographics. Our ability to provide tailored printing and custom shape designs was crucial in meeting their needs.

-

Starvie OEM Success: With growing demand for high-performance gear, Starvie partnered with us to produce rackets featuring a balanced blend of 12k and 18k carbon fiber. This collaboration not only strengthened their product catalog but also resulted in higher customer satisfaction due to improved racket performance.

These examples underscore the critical role that manufacturing innovation and customization play in building strong OEM partnerships5 and propelling business growth in the padel industry.

Looking ahead, the padel industry is positioned for continued growth, fueled by evolving trends and technological innovations. For B2B procurement managers, this creates an ideal environment for expanding product portfolios and exploring new market segments.

-

Invest in Advanced Manufacturing Partners: Choose a supplier with robust quality assurance and quick turnaround capabilities. This reduces lead times and supports the agile demands of the current market.

-

Prioritize Customization Options: Custom padel rackets not only drive customer engagement but also provide an edge in highly competitive markets. Evaluate suppliers who offer comprehensive customization including unique shapes, printing, and component personalization.

-

Leverage Data-Driven Insights: Stay informed about market trends through regular analysis. Data such as material performance comparisons and product lifecycle metrics can inform better procurement decisions.

-

Build Strategic OEM Relationships: Form long-term partnerships with manufacturers known for innovation and quality. This helps in securing favorable terms, reliable supply chains, and opportunities for collaborative product development.

-

Adopt Agile Practices: With rapid market changes, having partners that can adapt quickly is essential. Embracing agile manufacturing processes ensures your product offerings remain current and competitive.

The padel racket industry presents a unique confluence of rising global participation, manufacturing innovation, and demand for customized solutions. For B2B decision makers, understanding these trends is crucial for making informed procurement decisions that drive competitive differentiation and market growth.

At NEX Padel, we have harnessed advanced production techniques and a deep understanding of market dynamics to offer high-quality, tailor-made products. Our commitment to innovation—using state-of-the-art materials such as various carbon fiber types and offering bespoke customization options—ensures that every padel racket we produce exceeds industry standards. B2B partners can rely on our expertise not only for reliable supply chain efficiency but also for pushing the boundaries of what padel rackets can achieve in performance and design.

By aligning with forward-thinking manufacturers and leveraging the latest industry insights, procurement managers can unlock substantial value and position their brands at the forefront of a rapidly evolving sports market.

Q1: What factors contribute to the growing popularity of padel rackets?

A1: The rapid growth of the padel racket market is driven by increased global participation, advancements in manufacturing technologies such as carbon fiber innovations, and rising demand for customizable products that meet both performance and aesthetic requirements.

Q2: How does customization enhance the performance of padel rackets?

A2: Customization allows manufacturers to tailor the racket’s shape, balance, and weight distribution for optimal performance. Additionally, personalized features such as custom printing and branded components help differentiate products in a competitive market while ensuring that the equipment meets the specific needs of professional athletes and distributors.

Q3: What role does high-performance manufacturing play in OEM partnerships?

A3: High-performance manufacturing ensures consistent quality, precise material usage like 3k, 12k, and 18k carbon fibers, and fast turnaround times. This reliability and technological superiority are key factors in establishing and maintaining successful OEM partnerships in the competitive sports equipment market.

-

Advanced Manufacturing Innovation: Click to learn about cutting-edge innovations in manufacturing, how they enhance production efficiency, and drive competitive advantages in B2B markets. ↩

-

Carbon Fiber: Click to explore detailed insights into carbon fiber technology, including its manufacturing processes, properties, and benefits for high-performance sporting equipment. ↩

-

Custom Padel Rackets: Click to discover the strategic benefits of offering customized padel rackets, from brand differentiation to tailored performance enhancements. ↩ ↩2

-

Rapid Prototyping: Click to delve into the rapid prototyping process, exploring its importance in agile manufacturing and how it accelerates product development cycles. ↩

-

OEM Partnerships: Click to understand the dynamics of OEM partnerships, their role in supply chain efficiency, and how strategic collaborations boost product innovation. ↩