A quick answer: The optimal padel racket design balances weight distribution to maximize maneuverability, stability, and power. This balance is achieved by carefully calibrating the racket's weight range, center of gravity, materials such as carbon fiber1, and overall design to meet specific player and manufacturing requirements.

Padel racket design is a critical factor in performance optimization. For product managers and technical buyers in B2B sporting goods, understanding technical details such as weight distribution, balance point, material selection, and manufacturing efficiency is essential. In this article, we explore how weight distribution influences play dynamics and production efficiency in high-performance padel rackets.

The design and performance of padel rackets greatly depend on the precise engineering of weight distribution. Manufacturers face the challenge of creating rackets that provide an optimal blend of power, control, and durability while maintaining production efficiency. Some of the main issues include:

- Inconsistent performance due to improper weight allocation.

- Manufacturing difficulties when using advanced materials like 3k, 12k, or 18k carbon fiber.

- Player discomfort or injury if the balance point is skewed and does not suit different playing styles.

- Inefficient production processes that delay timely order fulfillment.

This problem is particularly significant for B2B purchasers who need evidence-backed technical insights to ensure that a product meets both market expectations and manufacturing standards.

The influence of weight distribution in padel rackets arises from several factors:

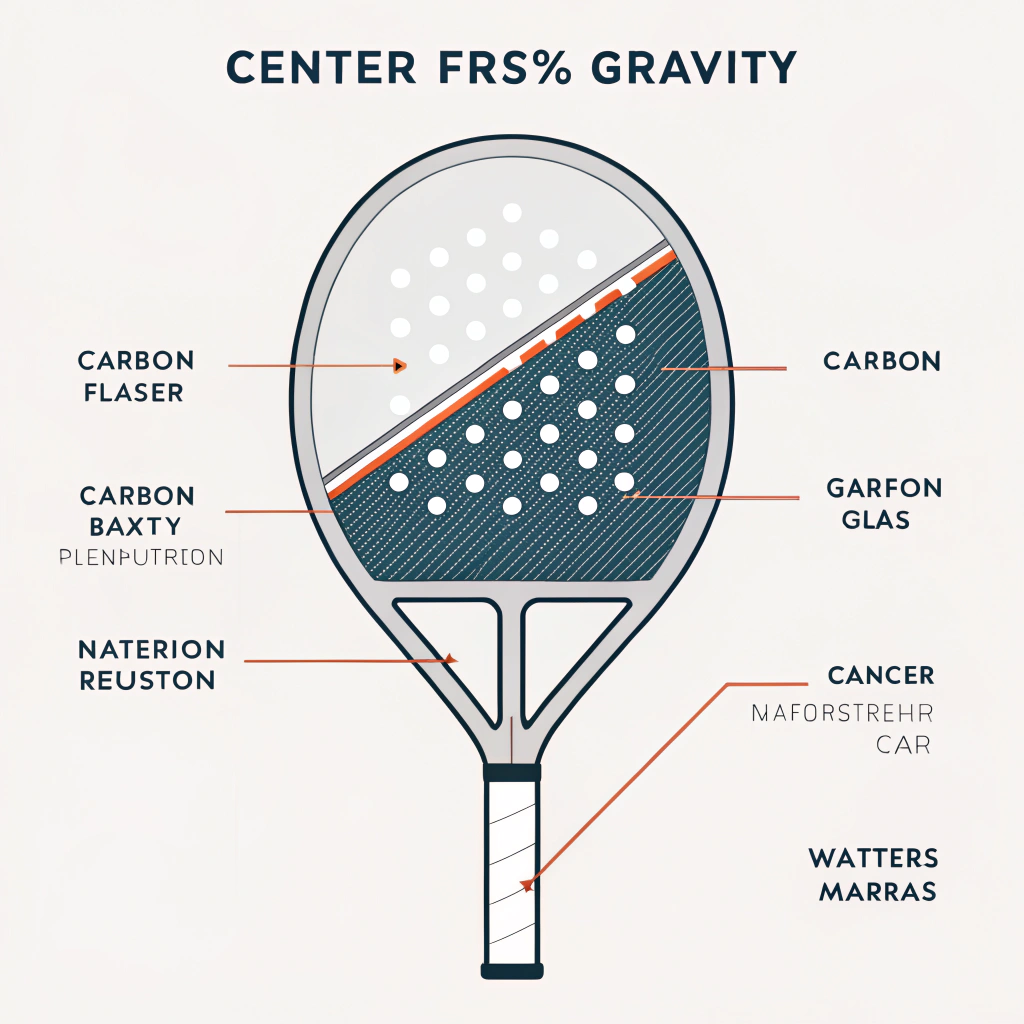

The materials used—ranging from fiberglass to multiple grades of carbon fiber—are chosen for their strength, flexibility, and weight. Each material impacts the final weight and rigidity of the racket, and must be optimized to create a product that is both durable and suitable for players of various playing styles.

The placement of mass within the racket, known as the balance point or center of gravity2, is a key technical element. A head-heavy racket can offer more power in strokes, while a more balanced or handle-heavy design increases maneuverability. For example, a racket with the center of gravity too far forward might boost stroke impact but at the risk of causing player fatigue or discomfort over long matches.

High-performance padel rackets require precision manufacturing techniques. Our factory methods emphasize:

- Rapid prototyping and sampling.

- Advanced production techniques that ensure consistent weight distribution.

- Custom manufacturing solutions3 tailored to specific design requirements (for example, full customization of shape, print, and color).

Any variations in these factors can lead to inconsistencies in performance parameters.

The weight distribution not only affects the physical handling of the racket but also plays a crucial role in energy transmission through the racket during impact:

- Stability: A well-balanced racket reduces the risk of twisting on impact, enhancing accuracy.

- Maneuverability: Lighter rackets or those with balanced weight distribution allow for faster swings and more controlled directional changes.

- Vibration Reduction: Properly distributed weight minimizes excessive vibrations, reducing the risk of injuries.

To address these challenges, manufacturers must adopt a solution-oriented approach. Below are detailed strategies used in the industry, along with technical insights from our operations at NEX Padel.

Selecting the right carbon fiber grade (3k, 12k, or 18k) is critical. Each option offers a different balance between weight and strength:

- 3k Carbon Fiber: Provides lighter weight options with a focus on flexibility and cost efficiency.

- 12k Carbon Fiber: Offers a balanced profile between rigidity and weight control.

- 18k Carbon Fiber: Prioritizes strength and durability, often resulting in heavier, more power-centric rackets.

Creating a custom padel racket involves meticulous weight balancing. The design process often includes:

- CAD simulations4 to predict weight distribution across different models.

- Prototype testing where real-world performance is measured.

- Iterative adjustments based on performance data and player feedback.

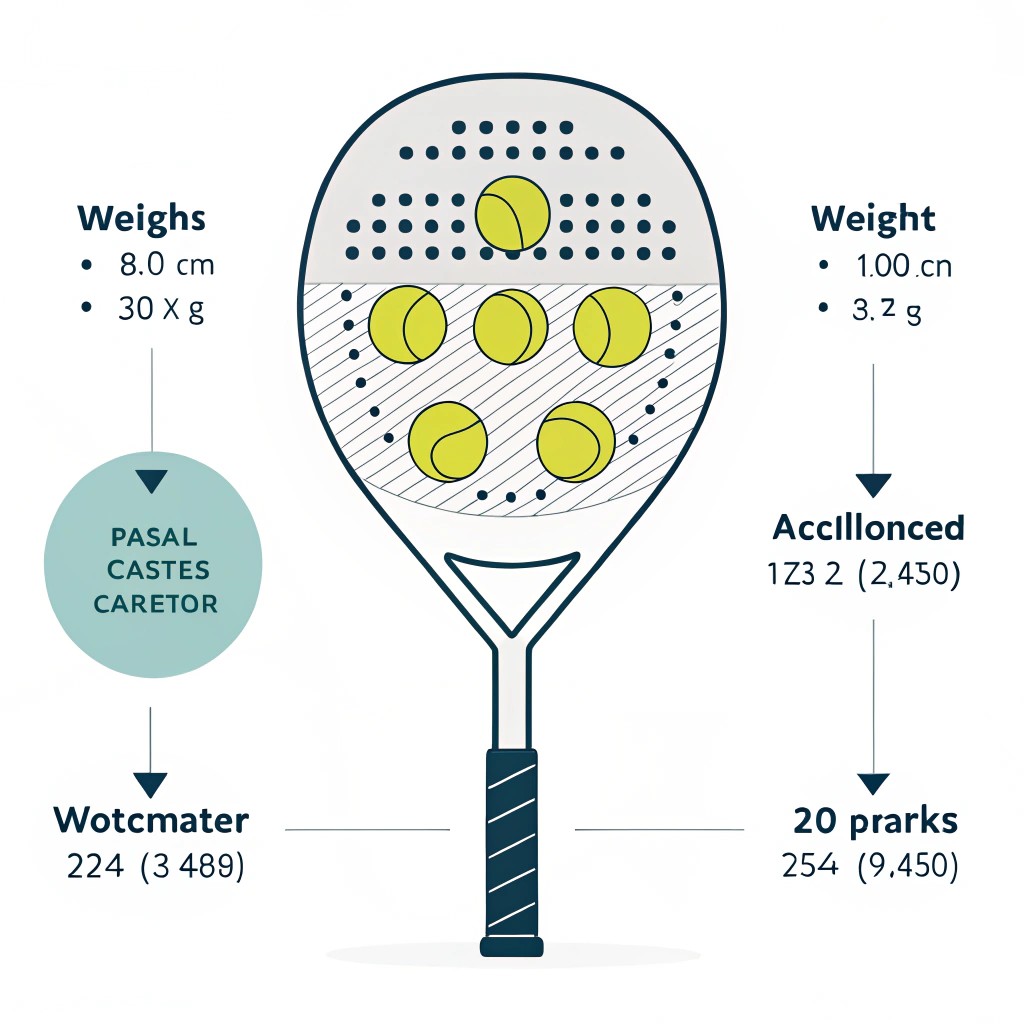

The following table provides a simplified comparison of design choices impacting weight distribution:

| Parameter | Lighter Racket | Heavier Racket |

|---|---|---|

| Swing Ease | High maneuverability | Increased stability |

| Power | Moderate power | Higher power output |

| Player Fatigue | Lower strain on the arm | Higher muscular demand |

| Ideal Player Profile | Beginners/players with less arm strength | Strong/thriving athletes |

| Manufacturing Ease | Faster production, simpler mold designs | Requires advanced precision |

This table helps guide product managers in selecting the appropriate design based on their target market and performance expectations.

Our approach at NEX Padel leverages advanced factory insight:

- Rapid Sampling5: Quick turnaround designs allow for testing multiple design iterations, ensuring that the best balance of weight and performance is achieved.

- Custom manufacturing solutions3: We offer full customization not only of the racket shape but also design elements such as customizable logos on hand grips and handle covers. This tailored approach allows our partners to differentiate their products in a competitive market.

- Quality Control: Every batch undergoes rigorous quality checks focusing on weight consistency and material adhesion, drastically reducing the risk of performance variance.

Consider a client project where the goal was to achieve a padel racket that combined agility with power. By leveraging our custom weight tuning:

- The engineering team used 12k carbon fiber for a balanced rigid structure.

- The center of gravity was adjusted to a mid-range position, optimizing both swing speed and stability.

- Multiple prototypes were tested, and players reported improved maneuverability during quick directional changes while retaining power in high-impact shots.

This case study demonstrates how thorough engineering and rapid prototyping can produce a product that meets competitive standards and player preferences.

When optimizing padel racket performance through weight distribution, several factors must be addressed:

- Player Variability: Different players require different balances. A one-size-fits-all approach does not work; customization based on target demographics is often necessary.

- Usage Scenarios: Rackets designed for casual play might prioritize maneuverability, while competitive or training rackets might focus on power and stability.

- Manufacturing Constraints: Advanced materials and custom designs require precise manufacturing techniques; deviations during production can affect balance and overall performance.

Engineers and product managers should note that:

- Fine-tuning the balance point can have a significant effect on play dynamics.

- Consistent quality control is essential to maintain performance across production batches.

- Close collaboration between design teams and manufacturing experts can prevent common pitfalls associated with weight distribution inconsistencies.

For firms aiming to enhance their padel racket offerings, consider the following recommendations:

- Conduct detailed CAD simulations to model weight distribution early in the design process.

- Implement rigorous quality control protocols at each stage of production.

- Engage with players for feedback during prototype testing to refine the balance point.

- Adopt flexible manufacturing processes that allow for rapid iteration and customization.

To conclude, a well-designed padel racket requires meticulous attention to weight distribution. By adopting advanced materials, precise engineering processes, and custom manufacturing techniques, manufacturers can create rackets that not only boost performance on the court but also offer a competitive advantage in the market. At NEX Padel, our commitment to innovation and quality control ensures that our products meet the highest standards, providing you with the confidence to make informed B2B purchasing decisions.

If you are a product manager or technical buyer seeking to elevate your padel racket line, consider implementing these strategies to optimize your product’s performance and reliability. Reach out to NEX Padel for further discussions on how our advanced production techniques can be integrated into your next project.

Q: Is it better to have a lighter or heavier padel racket?

A: Generally, lighter padel rackets are preferred for players seeking ease of maneuverability and reduced arm fatigue, while heavier rackets offer increased stability and power. The choice depends on individual player strength and playing style.

Q: Why do padel rackets have a weight range?

A: Padel rackets are designed with a weight range to cater to various playing styles and physical capabilities. A proper weight selection ensures optimal balance, reduces the risk of player injury, and maintains performance efficiency on the court.

Q: Does the weight of the racket matter?

A: Yes, the weight of a padel racket plays a crucial role in both its maneuverability and stability. Lighter rackets are generally more agile, while heavier ones provide more stable performance, making it important for players to choose a weight that suits their technique and strength.

-

carbon fiber: Click to learn about the properties, manufacturing processes, and performance benefits of carbon fiber in sporting goods design. ↩ ↩

-

center of gravity: Click to understand how the center of gravity influences racket balance, maneuverability, and overall performance on the court. ↩ ↩

-

custom manufacturing solutions: Click to learn about custom manufacturing methods that allow for tailored production runs to meet specific design and performance requirements. ↩ ↩ ↩2

-

CAD simulations: Click to explore how Computer-Aided Design (CAD) simulations help predict weight distribution and optimize design parameters. ↩ ↩

-

Rapid Sampling: Click to delve into the rapid sampling process and its role in iterating design prototypes quickly for performance verification. ↩ ↩