The perfect padel racket is defined by its materials, design, and customization1 options, all of which must align with your performance and business needs. In today's competitive B2B landscape, selecting the best padel racket involves evaluating technical specifications—from the type of carbon fiber2 used to the unique shapes like Diamond, Round, and Teardrop—to ensure durable, high-performance products that cater to various levels of play.

For sports equipment procurement managers, choosing the right padel racket supplier is critical. With increasing demand for high-performance sporting goods, especially in the padel industry, purchasing decisions must be based on both technical details and production efficiency. Buyers are now comparing aspects like material quality, shape performance, customization options, and overall cost-effectiveness. NEX Padel leverages advanced production techniques and offers a rich variety of options, making it easier for you to meet the unique demands of your customers.

In this article, we delve into key topics such as material differences, shape influences on gameplay, and the benefits of customization. We also highlight best practices and actionable insights for selecting the ideal padel racket supplier.

One of the major factors influencing the performance of a padel racket is the type of material used. At NEX Padel, we use a range of materials—from fiberglass to various grades of carbon fiber (including 3k, 12k, and 18k)—to create rackets that are durable, lightweight, and highly responsive.

Fiberglass padel rackets offer a balanced flexibility and durability, making them suitable for beginners or intermediate players. In contrast, carbon fiber variants provide increased stiffness and power, catering to advanced players who need precision and support during rapid gameplay.

Below is a comparative table that outlines the key attributes of each material:

| Material | Durability | Flexibility | Weight | Ideal For | Cost-Effectiveness |

|---|---|---|---|---|---|

| Fiberglass | Medium | High | Light | Beginners, Intermediate | High |

| 3k Carbon Fiber | High | Medium | Light | Competitive Play | Moderate |

| 12k Carbon Fiber | Very High | Low | Light | Advanced Players | Higher |

| 18k Carbon Fiber | Highest | Very Low | Ultra-light | Professional Precision | Premium |

Note: The trade-offs between weight, rigidity, and cost are essential when deciding which material aligns with your target market.

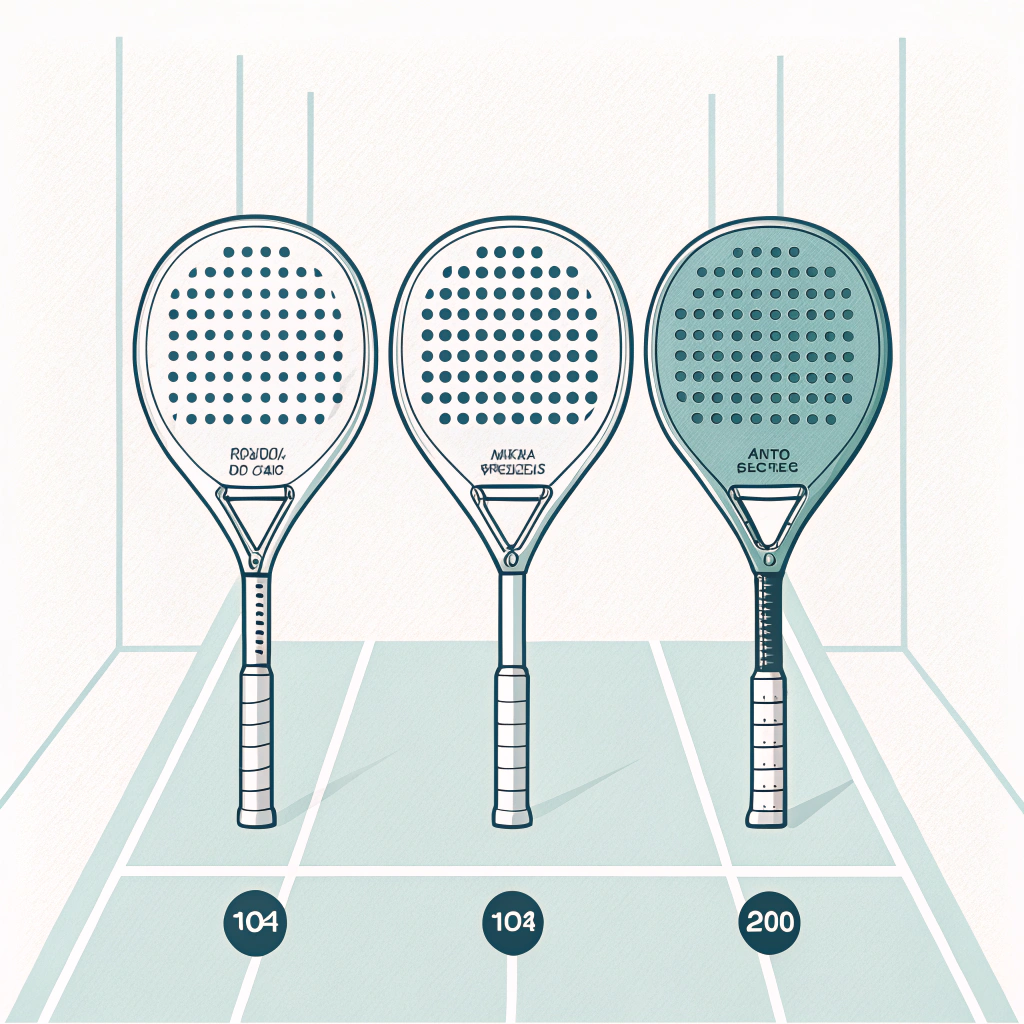

The shape of a padel racket significantly affects its playing characteristics. At NEX Padel, we offer three distinct shapes—Diamond, Round, and Teardrop—each with unique benefits.

- Diamond Shape: This design provides a concentrated sweet spot at the tip, which can offer more power for aggressive players. It is often preferred by advanced users who can control high-speed shots.

- Round Shape: Known for its broader sweet spot, round shapes offer enhanced control with a lower balance. This makes it ideal for beginners and intermediate players, as it minimizes the impact of off-center hits.

- Teardrop Shape: A compromise between the round and diamond shapes, teardrop rackets present a balance of power and control, appealing to players who value versatility.

Below is a table that summarizes key aspects of each shape:

| Racket Shape | Sweet Spot Location | Gameplay Style | Target Audience | Balance Ratio |

|---|---|---|---|---|

| Diamond | Tip | Powerful, aggressive | Advanced players | High |

| Round | Center | Controlled, precise | Beginners/Intermediate | Low |

| Teardrop | Mid-section | Balanced performance | Versatile, all-around use | Moderate |

In a competitive B2B landscape, the ability to customize products is a distinct advantage. NEX Padel offers extensive customization options that allow you to tailor padel rackets and grip accessories to your brand's requirements. Custom options include:

- Racket Shape Variation: Choose among Diamond, Round, or Teardrop shapes, or even request fully customized shapes.

- Material Selection: Select the appropriate material from fiberglass to various carbon fiber grades (3k, 12k, 18k) depending on your target customers' playing styles.

- Custom Printing & Color Options: Enhance brand identity with personalized designs and color schemes.

- Logo Customization on Hand Grip and Cover: Ensure that even smaller components of the racket reflect your company’s brand.

Quality control is a pinnacle of our production process. From rapid prototyping to consistent manufacturing, every padel racket undergoes strict monitoring and testing. This ensures each product not only meets but exceeds industry performance standards.

When sourcing padel rackets for your distribution network, follow these steps to make a well-informed decision:

-

Define Your Customer’s Needs

- Identify whether your target market includes beginners, intermediate players, or advanced professionals.

- Assess the level of customization that appeals most to your customers. For example, if brand identity is essential, consider options with extensive printing and design customizations.

-

Compare Material Options

- Evaluate the benefits and trade-offs among fiberglass, 3k carbon, 12k carbon, and 18k carbon.

- Use comparative tables (like the one provided earlier) to visualize differences in durability, flexibility, and cost.

-

Analyze Racket Shapes and Performance

- Understand how different shapes affect the sweet spot and gameplay style.

- Map your product offerings against customer preferences—for example, round rackets for beginners versus diamond shapes for aggressive players.

-

Review Customization Capabilities

- Ensure that your chosen supplier can meet the customization needs such as unique printing options, shape alterations, and branding on accessories.

- Confirm that production timelines align with your procurement schedule. Quick sampling and on-time delivery are crucial.

-

Conduct a Quality and Price Comparison

- Request sample products to evaluate both performance and manufacturing quality.

- Compare supplier benefits such as production precision, durability, and customer support.

Below is a step-by-step checklist in table format for your evaluation process:

| Step | Key Considerations | Action Required |

|---|---|---|

| Define Customer Needs | Skill level, customization, target demographic | Survey customer base & market analysis |

| Compare Material Options | Fiberglass vs. Carbon Variants | Analyze performance data & cost metrics |

| Analyze Racket Shapes | Sweet spot location, gameplay impact | Test samples & feedback collection |

| Review Customization Capabilities | Design printing, handle customization | Consult with supplier & request samples |

| Quality and Price Comparison | Durability, precision manufacturing, delivery timelines | Request trials and detailed quotes |

For B2B procurement managers, production efficiency is just as important as product performance. NEX Padel prides itself on streamlined production methods that reduce lead times without compromising on quality. The following aspects highlight how our processes contribute to a competitive edge:

- Rapid Prototyping3: Quickly validate product designs with fast and reliable sampling.

- Precision Production4: Advanced manufacturing techniques are employed to maintain consistent product dimensions and material distribution.

- Strict Quality Control5: Each batch undergoes rigorous testing to ensure that every product meets stringent quality standards.

- Efficient Supply Chain Management: On-time deliveries reduce inventory holding costs and maintain strong customer relationships.

Our comprehensive quality assurance protocol means you receive products that not only perform well but also maintain their integrity over extended periods of use. This consistency is essential for sustaining consumer trust and minimizing post-sale issues.

In the highly competitive sporting goods market, manufacturers like NEX Padel have achieved significant success by focusing on both innovation and customer-centric production. Here are some real-world examples of how our approach has added value:

-

Case Study: High-Performance Customization

- A leading sports brand required a lineup of padel rackets that could cater to both amateur and professional levels. By selecting a mix of fiberglass and advanced carbon fiber variants and offering a range of customization options, we enabled the brand to capture a broader market. The flexibility in choosing between Diamond, Round, and Teardrop shapes allowed players to select rackets that best complemented their playing styles, resulting in increased customer satisfaction and repeat business.

-

Case Study: Cost-Effective Production with Minimal Lead Times

- Time-to-market is critical in the sporting goods industry. We worked with a retail chain looking for quick turnaround times without sacrificing quality. Our streamlined production process, combined with effective quality control measures, ensured that the new padel rackets were delivered on schedule, significantly reducing inventory gaps and driving sales.

These examples illustrate that whether you require high customization, precision performance, or cost-effective production, choosing the right supplier like NEX Padel can elevate your product offering and drive business success.

When evaluating potential suppliers for padel rackets, consider how each option aligns with your customer needs and business goals. NEX Padel stands out by providing a robust mix of materials, diverse racket shapes, flexible customization options, and a commitment to precision production. The result is a product line that caters to various skill levels and playing styles, ensuring that you meet the evolving demands of your market.

Our rigorous approach—ranging from detailed material analysis to production quality assurance—positions us as a trusted partner in your procurement process. We encourage you to juxtapose your product requirements with our offerings and experience the difference that high-performance, precision-engineered padel rackets can make for your business.

Take action today by reaching out to our team for detailed product specifications, customized solutions, and competitive quotes. With NEX Padel, you are investing in quality, reliability, and innovation—a winning combination for the modern sports market.

-

How to choose the perfect racket?

Ideally, select a racket with a larger head size to offer a larger sweet spot. Rackets with larger sweet spots are especially useful for beginners as they allow a margin for error during technique development. -

How to find padel racket sweet spot?

Round blades typically have a lower balance that results in a broader surface area. This design provides a higher sweet spot centrally located on the racket, whereas diamond-shaped blades concentrate the sweet spot at the tip. -

What makes a padel racket better?

A racket’s shape significantly influences performance, from defining the sweet spot to impacting gameplay style. Choosing the right shape enhances control and power, leading to more effective shots and overall improved performance.

-

Customization: Reading the article will help you understand how tailoring products to specific market needs can enhance brand identity and meet customer expectations. ↩

-

Carbon Fiber: Click to learn more about the various grades and applications of carbon fiber in high-performance sporting goods. ↩

-

Rapid Prototyping: Explore techniques that enable quick product validation and help streamline the development cycle. ↩

-

Precision Production: Discover advanced manufacturing methods that ensure consistent quality and exact specifications in production. ↩

-

Strict Quality Control: Learn about comprehensive testing methods that help maintain product integrity and reduce post-sale issues. ↩