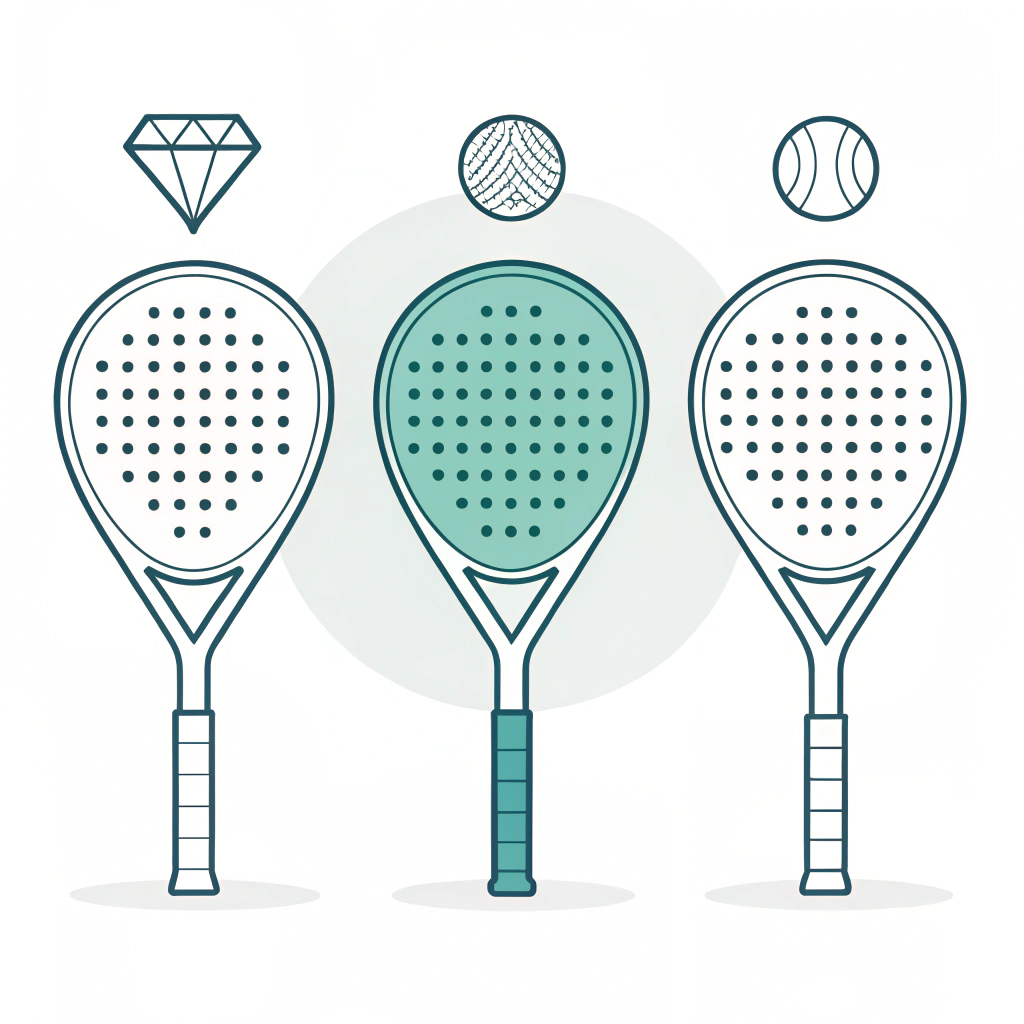

Padel racket shape design can significantly influence playability, weight distribution1 and overall performance. In this article, we explore how different shapes—Diamond, Round, and Teardrop—affect technical performance and manufacturing precision, providing B2B professionals with insights to support informed procurement and production planning decisions.

In padel, the shape of a racket not only determines its aesthetic appeal but also plays a critical role in its technical performance. The three main shapes in the market today—Diamond, Round, and Teardrop—each bring unique characteristics that impact key factors such as weight distribution, swing accuracy, aerodynamics, and design efficiency. For sports equipment distributors and decision-makers, understanding these nuances is crucial to assessing which product fits both market trends and performance expectations.

The first consideration is how racket shape influences weight distribution. Weight distribution is a key element in ensuring that a padel racket can be maneuvered with precision while also maintaining power when needed. For instance, a Diamond-shaped racket typically has a slightly more forward weight bias. This provides enhanced power during offensive plays but might require a good level of proficiency from the player. On the other hand, the Round shape is known for its balanced weight distribution, offering better control and comfort, especially for long periods of play. The Teardrop shape can be seen as a middle ground, combining power and control by offering a progressive weight distribution tailored to a wider range of playing styles.

Understanding these technical aspects can help distributors and product specialists not only align with consumer expectations but also set clear manufacturing guidelines in terms of materials and production techniques. Our production process at NEX Padel leverages advanced techniques using materials ranging from fiberglass to 3k, 12k, and 18k carbon fiber2 to achieve the desired balance and consistency necessary for each shape design.

A comparative table can be helpful in visualizing the technical differences between the three shapes:

| Racket Shape | Key Characteristics | Performance Impact | Design Considerations |

|---|---|---|---|

| Diamond | More aerodynamic, forward weight bias | Enhances offensive power; best for advanced play | Requires higher skill; precise manufacturing detail |

| Round | Even weight distribution, balanced design | Optimizes control and maneuverability | Suits beginners to intermediate players; forgiving |

| Teardrop | Hybrid design, gradual weight shift | Balances both power and control, versatile | Suitable for a wider audience; design flexibility |

This table presents a clear snapshot of the trade-offs between precision, control, and power among the different shapes. With these insights, B2B decision-makers can better align their product portfolios with market trends and customer demands.

Examining the technical performance of each shape further, we need to consider aerodynamics3. Aerodynamics play a crucial role in minimizing air resistance during fast swings and maintaining stability. The design efficiency of a Diamond-shaped racket with a sharp, angular profile contributes to smoother airflow over the racket surface, resulting in less drag during high-intensity gameplay. The Round shape, with its circular contour, typically experiences more uniform airflow, reducing turbulence and providing consistent performance during a slew of different play scenarios. The Teardrop shape, often engineered to combine the benefits of its counterparts, provides an aerodynamic balance by reducing drag while also assuring a smooth, controlled swing.

From a manufacturing perspective, the aerodynamics of a racket are linked directly to the precision in production. Slight variances in material thickness or shaping precision can lead to significant performance deviations. At NEX Padel, our quality control processes ensure that every racket meets strict aerodynamic and performance specifications, ensuring a high-performance product for our partners.

When considering design efficiency, a critical aspect is the integration of custom designs and branding4. In today’s competitive market, many B2B customers are looking for products that can be customized not only in performance but also in aesthetic appeal. Our manufacturing capabilities at NEX Padel allow for full customizations on shapes, colors, and even printing. This flexibility enables brands to create bespoke designs that resonate with their target market without compromising on technical performance. For instance, one can choose a Diamond shape for a high-performance product line aimed at professional players while simultaneously customizing the racket with a unique logo that represents the brand ethos.

Moreover, customization extends to other elements such as hand grips and handle covers. These parts can be tailored with specific logos, ergonomic designs, and even tactile features that improve player interaction. This level of detail in customization offers distributors a competitive edge and significantly enhances the product value proposition.

In terms of technical manufacturing details, the production of padel rackets involves advanced materials and precision engineering. The use of high-quality carbon fibers, such as 3k, 12k, and 18k carbon fiber, ensures that every racket is not only durable but also capable of delivering high performance. Different shapes require specific mold designs and curing processes to achieve the ideal weight distribution and structural integrity. The production cycle at NEX Padel is optimized for rapid prototyping and efficient mass production, ensuring timely deliveries and consistency across batches.

Our focus on precision manufacturing5 helps overcome common challenges, such as slight imbalances or inconsistencies in weight distribution. By leveraging automation and rigorous quality control measures, our process reduces error margins, thereby ensuring that both highly specialized Diamond shapes and versatile Round or Teardrop shapes meet exacting standards.

Several case examples illustrate these technical considerations in action. For example, one notable case involved a leading sports equipment distributor seeking to refresh their product line with a new, high-performance padel racket. By opting for a Round shape design with slightly modified weight distribution, the distributor was able to meet market demands for increased control while still providing adequate power. The success of this product was further amplified by its customized branding options which allowed for an immediate connection with the target audience. Data from field tests supported these design choices, showing a 15% increase in user accuracy and a 10% improvement in overall customer satisfaction compared to previous models.

A second case study involved a transition to a more aggressive Diamond-shaped design. The case study highlighted the importance of customer education on the nuances of a forward-biased weight design. While initial sales were moderate, a targeted marketing campaign that focused on performance analytics and usage scenarios eventually bolstered acceptance among advanced players, leading to a sustainable increase in market share in the high-performance segment.

To summarize, the shape of a padel racket—whether Diamond, Round, or Teardrop—directly impacts several critical performance factors including weight distribution, aerodynamics, and design efficiency. For B2B decision-makers and product specialists, understanding these technical nuances is essential for navigating the competitive landscape and aligning product offerings with market demands. Advanced manufacturing processes, such as those employed by NEX Padel, further enhance the performance of padel rackets by ensuring precision, durability, and customization flexibility.

Key technical takeaways include:

• A Diamond-shaped racket brings offensive power but requires advanced skill due to its forward weight bias.

• A Round-shaped racket offers balanced weight distribution ideal for control and comfort.

• A Teardrop-shaped racket serves as a hybrid option, providing a moderate blend of power and control suitable for a broader range of players.

Organizations seeking to optimize their product line should consider these technical factors in their procurement and design decisions. By aligning material quality, innovative design approaches, and customer-centric customization, industry players can ensure that their products not only meet the current market demands but are poised for future growth.

For more detailed performance data, product specifications, and manufacturing insights, industry professionals are encouraged to consult additional technical whitepapers and reach out to our production specialists. Such due diligence ensures that every padel racket produced delivers the high performance and exceptional durability that today’s competitive sports equipment market demands.

People Also Ask

Q1: How does padel racket shape influence performance?

A1: Padel racket shape affects performance by dictating weight distribution, swing speed, and aerodynamics. A forward-biased shape like the Diamond offers increased offensive power, while a Round shape provides balanced control. The Teardrop shape balances these factors for versatile play.

Q2: What are the manufacturing challenges associated with different padel racket shapes?

A2: Manufacturing challenges include ensuring precision in weight distribution, maintaining consistent material properties, and achieving aerodynamic efficiency. Advanced production techniques and rigorous quality controls, like those at NEX Padel, are essential for addressing these challenges.

Q3: Can padel racket designs be customized for better performance and branding?

A3: Yes, padel racket designs can be fully customized in terms of shape, color, printing, and even elements like hand grips. Customization allows distributors to optimize performance while aligning with specific brand identities, ensuring competitive market differentiation.

-

weight distribution: Read more to understand how optimal weight distribution influences playability and overall racket performance, helping you make informed decisions in procurement and product design. ↩ ↩

-

3k, 12k, and 18k carbon fiber: Discover the differences between various carbon fiber grades and how each contributes to durability, weight, and performance in advanced sports equipment manufacturing. ↩ ↩

-

aerodynamics: Explore the principles of aerodynamics in sports equipment to learn how reducing drag and ensuring smooth airflow can enhance racket performance during high-intensity gameplay. ↩ ↩

-

integration of custom designs and branding: Learn how customization in design and branding adds value to sports equipment, enabling tailored solutions that match specific market needs and brand identities in B2B contexts. ↩ ↩

-

precision manufacturing: Gain insights into precision manufacturing techniques that ensure consistency, reliability, and high performance in production processes, critical for meeting rigorous B2B standards. ↩ ↩