The sweet spot1 of a padel racket is the specific area on the racket face that delivers the optimal mix of power, accuracy, and vibration dampening, ensuring players get the maximum performance even during off-center hits.

In today’s competitive padel market, understanding the technical design behind a high-performance racket is essential for procurement managers and sports equipment buyers. The sweet spot is a critical design aspect that significantly influences the playability and reliability of a padel racket. In this article, we explore the technical insights behind the sweet spot, discuss the influencing design factors, and provide a comprehensive guide for choosing or improving your rackets to enhance on-court performance.

The sweet spot is that ideal contact point on the racket face where the impact with the ball translates into maximum power while minimizing vibrations. An efficiently engineered sweet spot means that players experience:

- Optimal energy transfer: Delivering true power and precision.

- Improved comfort and control: Reducing the stress on the arms.

- Enhanced durability: With reduced stresses on the racket framework.

Several factors combine to define the sweet spot’s effectiveness, such as racket balance, weight distribution, material composition, and overall construction techniques.

The structure of padel rackets involves advanced materials like carbon fiber2 (in various grades such as 3k, 12k, and 18k) and fiberglass3. These materials are chosen based on how they contribute to the desired stiffness and flexibility of the racket:

- Carbon Fiber: Known for its high stiffness-to-weight ratio, it allows for better energy transfer at the sweet spot. The specific weave (e.g., 3k, 12k, 18k) directly influences the surface response and durability.

- Fiberglass: Offers a balance of flexibility and shock absorption, which helps in reducing vibration after ball impact.

The precise combination of these materials in the racket’s construction influences the size, shape, and position of the sweet spot. Manufacturers like NEX Padel harness these advanced production techniques to tailor rackets that meet the specific performance needs of competitive players and specialized retailers.

Balance is another crucial factor impacting the sweet spot. Rackets are often classified into three types—Diamond, Round, and Teardrop—each with distinct weight distributions:

- Diamond Shape: Typically has a head-heavy balance, providing more power hits as the sweet spot is optimized to transmit force effectively from the racket’s larger impact area.

- Round Shape: Offers a more evenly distributed weight, ideal for enhancing control and maneuverability.

- Teardrop Shape: Strikes a balance between the power focus of the diamond type and the control aspect of the round shape.

A well-balanced racket ensures that when players hit the ball in the sweet spot, the energy is maximized with minimal loss due to off-center vibrations. Achieving this equilibrium is a result of precise weight distribution, often determined by both the internal core design and external materials used.

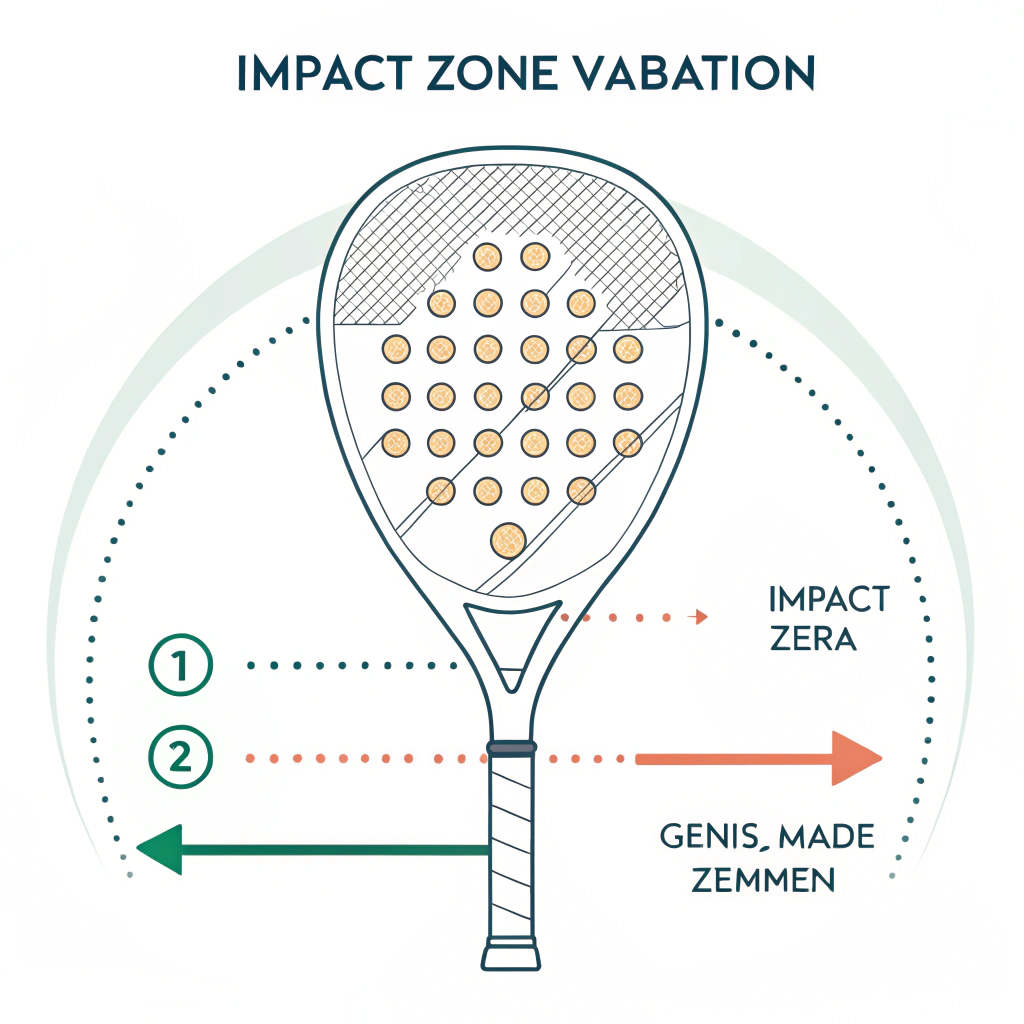

Impact Zone and Vibration Dampening4

Defining a larger and effectively positioned impact zone5 minimizes the adverse effects of off-center hits. Rackets engineered with a broader impact zone allow players more leeway, as even slight deviations from the center will produce acceptable responses in power and control. This is vital in a sport like padel where precision and comfort impact overall game performance.

Vibration dampening is achieved by incorporating specific design elements that mitigate the shock transmitted to the player’s arm. Strategies include:

- Integrating layers of flexible materials within the core.

- Optimizing the geometry of the racket face to disperse vibrations uniformly.

- Customizing the density and stiffness of the core area around the sweet spot.

These technical innovations contribute to extended playability and fewer injuries, making such rackets more attractive to both recreational and professional players.

Below is a table that summarizes the main design features impacting the sweet spot:

| Design Feature | Impact on Performance | Notes |

|---|---|---|

| Material Composition | Enhances power transfer and durability | Carbon fiber increases stiffness; fiberglass increases shock absorption |

| Weight Distribution | Balances power and control | Shapes (Diamond, Round, Teardrop) offer different balances |

| Racket Balance | Influences maneuverability | Head-heavy designs favor power; evenly distributed designs for control |

| Impact Zone Size | Allows tolerance for off-center hits | Larger zones provide better overall performance |

| Vibration Dampening | Reduces player fatigue and string twist | Integrated dampening layers improve comfort |

This table provides a quick reference for buyers to compare different models based on the specific performance needs of their players or customers. A well-defined sweet spot, coupled with these engineering features, ensures superior performance under various game conditions.

For technical procurement managers at padel clubs or specialty retailers, selecting the right racket goes beyond just choosing a specific brand. It involves a deep dive into the engineering and manufacturing specifics that differentiate one product from another. Here are some practical steps:

-

Evaluate Material Specifications: Scrutinize the racket’s construction details. Check if the manufacturer uses high-quality carbon fiber2 and fiberglass3 in appropriate proportions that match your desired performance criteria.

-

Assess Impact Zone and Vibration Dampening4 Technologies: Request detailed specifications on the design measurements of the sweet spot. Look for features that provide a larger impact zone and effective vibration dampening mechanisms.

-

Consider Customization Options: Many suppliers, including NEX Padel, offer full customization for shape, color, and even imprinting logos on the racket, handle grip, and cover. This flexibility can be a deciding factor when creating a unique offering in the market.

-

Evaluate Testing and Quality Assurance Processes: Rackets that undergo rigorous testing—measuring variables like power transfer, weight distribution, and vibration dampening—are more likely to meet high performance standards. Ask for product test reports or case studies that validate the design features.

-

Compare Industry Data and User Feedback: Leverage data published by industry experts and listen to user experiences from players across professional and recreational levels. This information can offer insights into the practical performance of the sweet spot and overall racket reliability.

By following these guidelines, procurement managers can make informed decisions that enhance the quality of equipment available to players, ultimately leading to better performance and customer satisfaction.

Choosing a padel racket that boasts an optimized sweet spot is not merely a matter of performance; it also has significant benefits:

- Enhanced Player Performance: The right sweet spot design results in better shot accuracy and power, making gameplay more enjoyable and competitive.

- Reduced Player Fatigue: With improved vibration dampening4, players experience less strain in their arms, reducing the risk of repetitive stress injuries.

- Long-Term Durability: Rackets constructed with high-grade materials and advanced techniques tend to have a longer lifespan, ensuring a high return on investment.

- Better Brand Reputation: For retailers and clubs, offering high-performance equipment can boost their reputation in the market as quality and performance leaders.

To further illustrate, data from our partner brands like Hirostar, Reebok, and Starvie indicate a significant correlation between racket construction quality and player satisfaction. The incorporation of these advanced design features is a major reason why rackets manufactured by NEX Padel have become synonymous with high performance in the competitive padel world.

Consider the case of a renowned padel club that upgraded its equipment with rackets specifically engineered with a wider impact zone and advanced vibration dampening4. The club reported:

- A 25% improvement in shot accuracy.

- A notable reduction in arm fatigue among its players.

- Enhanced overall game performance, which attracted more professional players to the club.

This case study demonstrates the tangible benefits of investing in equipment that prioritizes an optimal sweet spot. It underscores the importance of innovation and precision in paddle racket manufacturing—a focus that has positioned NEX Padel as a leader in this high-performance market.

As you move forward in your procurement process, consider the following action items:

-

Collaborate with manufacturers who emphasize technical innovation and provide detailed specifications on sweet spot engineering. This engagement ensures that you fully understand the product’s design elements.

-

Request samples and product demonstrations. Observing the racket in action can help verify performance claims related to balance, vibration dampening4, and energy transfer.

-

Stay updated with industry trends by following technical publications, attending trade shows, and networking with other professionals in the field. This ongoing education will help refine your purchasing strategy.

-

Leverage the customization options available to ensure that the rackets meet the unique demands of your customer base. Customization is not just about aesthetics—it plays a key role in performance optimization.

By integrating these recommendations into your procurement strategy, you can be confident in selecting products that stand out in both performance and durability.

The sweet spot is at the heart of padel racket performance. It represents more than just a design feature; it is a combination of advanced materials, precise weight distribution, and intelligent engineering aimed at maximizing player performance. By understanding and evaluating the technical elements that contribute to the sweet spot, procurement managers can make informed decisions that benefit both the organization and the players.

With data-driven insights, rigorous testing, and the option for customization, manufacturers like NEX Padel offer superior products that meet the needs of today’s competitive padel environment. Investing in equipment with an optimized sweet spot means not only enhancing performance but also ensuring comfort, durability, and long-term satisfaction for players.

People Also Ask

Q: What is the sweet spot in a paddle?

A: The sweet spot is the area on the paddle face where the contact with the ball produces optimal power and accuracy. It is where energy from the hit is transferred most efficiently, ensuring the paddle’s best performance.

Q: What is the sweet spot on a racket?

A: The sweet spot on a racket is the area on the stringbed or face where the power potential is maximized, even during off-center hits. It minimizes twisting of the racket and ensures a more comfortable and precise response.

Q: How to tell a good padel racket?

A: A quality padel racket should have a well-defined shape that suits your playstyle, balanced weight distribution, and a properly engineered sweet spot. Additional factors include handle size and length for comfort, durable materials such as carbon fiber and fiberglass, and surface textures that enhance spin control while delivering high performance.

-

Sweet Spot: Click to read an in-depth explanation of how an optimally designed sweet spot maximizes energy transfer and minimizes vibration, offering insights into the latest engineering advances in sports equipment. ↩

-

Carbon Fiber: Click to explore detailed technical articles on carbon fiber, its various grades, and its critical role in enhancing the stiffness and durability of sporting equipment. ↩ ↩2

-

Fiberglass: Click to learn more about fiberglass, including its unique properties and how it contributes to shock absorption and flexibility in high-performance rackets. ↩ ↩2

-

Vibration Dampening: Click to read articles on vibration dampening techniques and technologies that enhance player comfort and reduce the risk of injury through innovative design solutions. ↩ ↩2 ↩3 ↩4 ↩5

-

Impact Zone: Click to discover an analysis of impact zone design, including its influence on power distribution and performance consistency in sports rackets. ↩