Selecting the right OEM/ODM manufacturer1 for high-performance padel rackets is crucial. For procurement managers and business owners, partnering with a supplier like NEX Padel can make all the difference—thanks to our advanced production techniques2, diverse material options (including carbon fiber3 in 3k, 12k, and 18k grades), and highly customizable designs that meet international market demands.

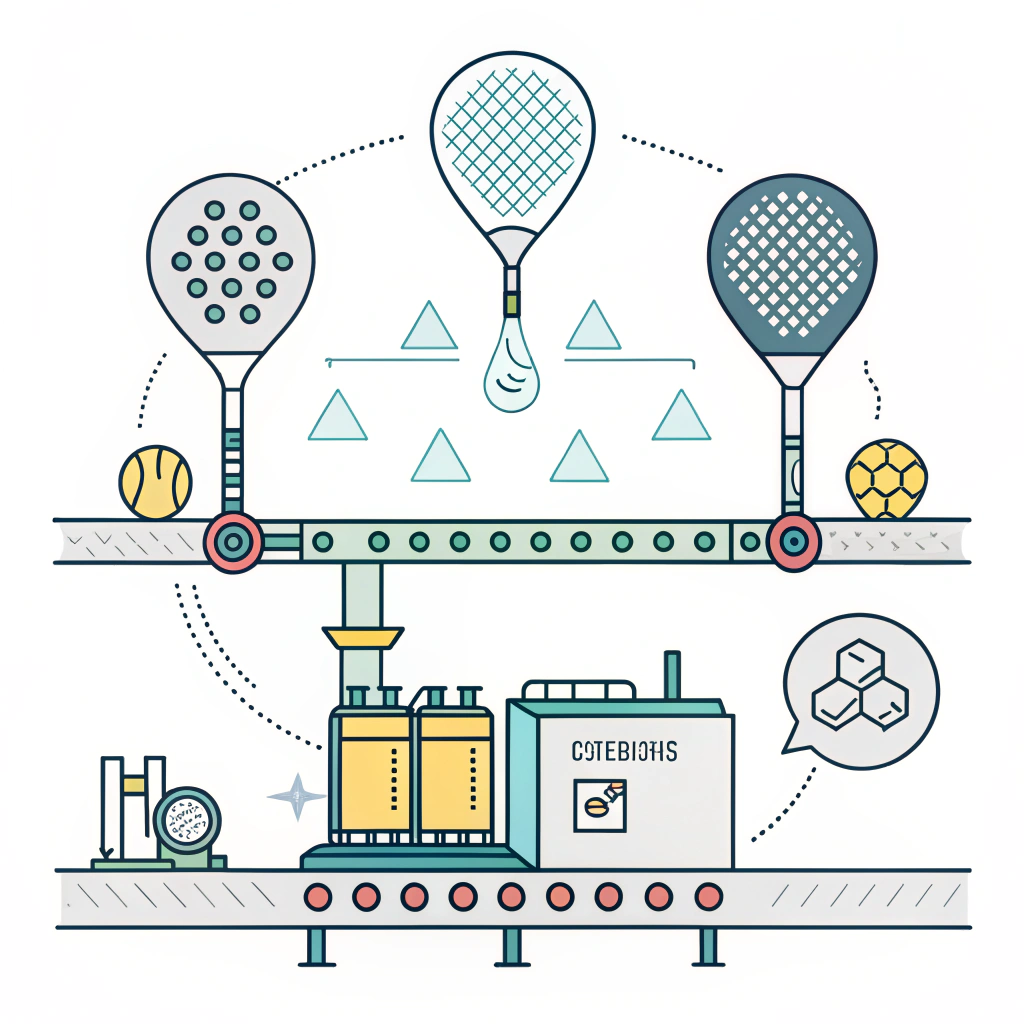

In today’s highly competitive sports equipment market, sourcing quality OEM padel paddles requires an in-depth evaluation of manufacturing capabilities, customization options, and production turnaround. Many companies face challenges such as unpredictable lead times, inconsistent product quality, and limited customization, which ultimately affect end-user satisfaction. When comparing options, the following factors are critical:

- Advanced production techniques ensuring precision and durability.

- Material diversity—from fiberglass to various grades of carbon fiber.

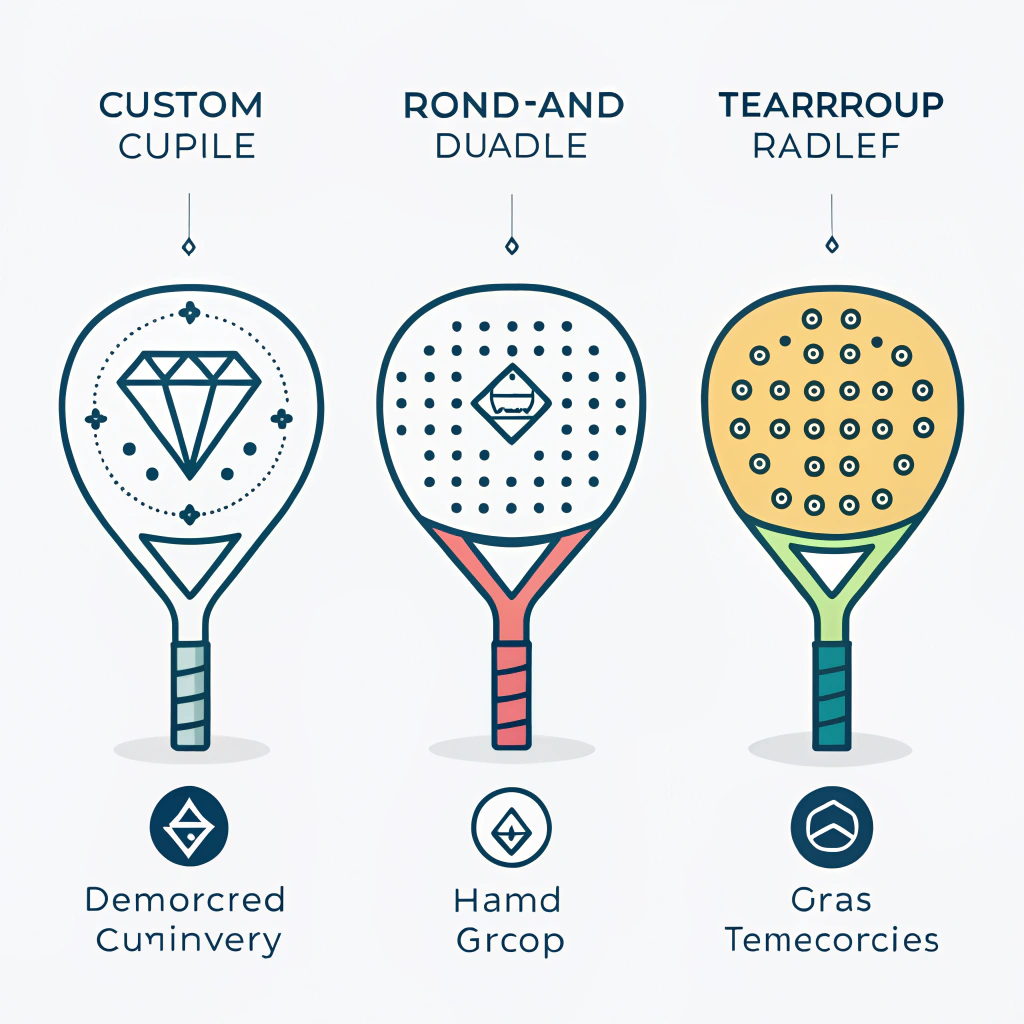

- Customization capabilities, such as unique shapes (Diamond, Round, Teardrop), custom prints, and accessory options like bespoke hand grips.

- Fast production cycles and on-time delivery even for small or large orders.

NEX Padel has consistently addressed these concerns by implementing rigorous quality control and using state-of-the-art manufacturing processes that adhere to international standards.

When evaluating padel paddle manufacturers, consider the following core criteria. A quick, side-by-side comparison helps to clarify the unique advantages offered by experienced OEM partners:

| Criteria | NEX Padel | Other Manufacturers |

|---|---|---|

| Material Options | Fiberglass; 3k/12k/18k carbon fiber | Limited to basic materials; minimal carbon variant options |

| Customization Flexibility | Fully customizable shapes, prints, logos on hand grips and frame covers | Standardized models with limited branding options |

| Production Techniques | Advanced production methods ensuring precision engineering; strict quality controls | Traditional processes with less stringent quality checks |

| Turnaround Time | Fast sampling and on-time delivery regardless of order size | Often longer lead times and inflexible production scheduling |

| Scale & Reliability | Trusted by international brands (e.g., Hirostar, Reebok) with robust quality assurance systems | Mixed reputations with occasional quality or timing issues |

| After-Sales and Support | Dedicated technical support and post-production consultation | Limited support post-production |

This table clearly demonstrates that suppliers like NEX Padel, with their focused expertise in high-performance padel rackets, excel in areas critical to modern procurement managers.

For many companies, the ability to offer unique, premium products is a significant market differentiator. With NEX Padel, the emphasis on customized sports equipment4 goes beyond aesthetics; it extends to performance enhancements and usability. Key customization features include:

- Custom Shapes: Whether you are targeting a traditional feel with a Round design, prefer the innovation of a Teardrop shape, or opt for the performance-oriented Diamond design, custom shape options provide a tailored experience for your customers.

- Material Variety: Advanced players and premium brands often require padel paddles composed of specialized materials like 3k, 12k, and 18k carbon fiber. These materials not only elevate performance but also enhance racket durability.

- Branded Accessories: In addition to paddle customization, options such as custom hand grips and handle covers elevate the overall brand experience, enabling companies to stand out in a crowded market.

The importance of customization becomes even more apparent when considering competitive pricing and fast turnaround times. With efficient sampling and manufacturing processes, many OEM partners—especially those with a strong technical background like NEX Padel—can adapt quickly to market trends and consumer demands without sacrificing quality or innovation.

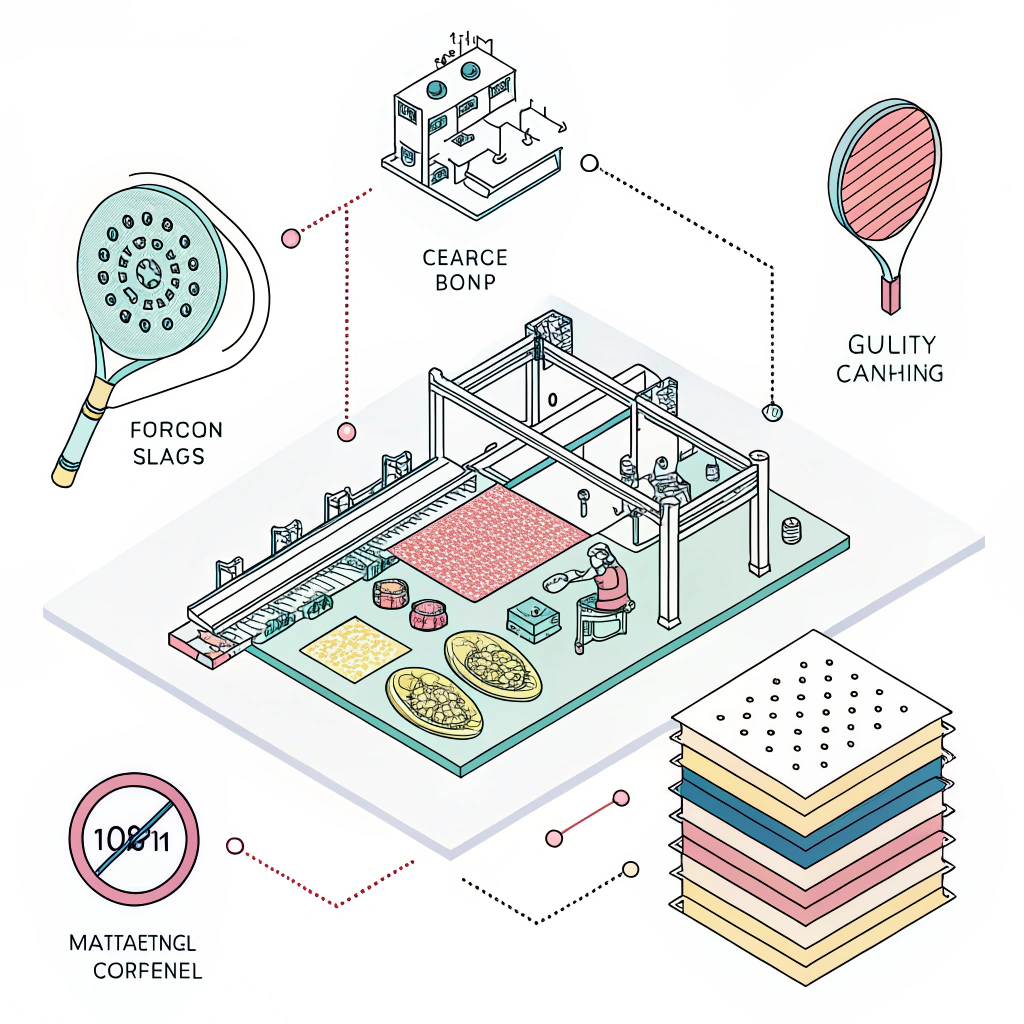

A high-performance padel paddle must combine lightweight design, power generation, and precise control. Achieving this balance involves a series of complex production steps, including material selection, molding, layering, and finishing. Below are several critical points that underscore the production superiority at NEX Padel:

- Material Integrity: The use of fiberglass for general durability, along with various grades of carbon fiber (3k for flexibility, 12k for balanced performance, and 18k for stiffness and power), ensures that each paddle is engineered to meet specific performance requirements. The careful selection of these materials is crucial in creating paddles that are both hard-hitting and forgiving.

- Advanced Engineering: Precision engineering, leveraging both modern CAD tools and traditional manufacturing expertise, allows NEX Padel to produce rackets that exhibit minimal variance and optimal structural integrity. This level of craftsmanship reduces the risk of defects and ensures consistent performance across large batches.

- Quality Control: With rigorous quality checks at every stage of production—from raw material inspection to final assembly—NEX Padel meets and often exceeds industry standards. This commitment to quality is a major differentiator for companies seeking reliable supply chains that offer consistent excellence.

- Rapid Prototyping and Turnaround: Fast sampling and iterative design are critical, especially when market conditions shift. NEX Padel’s ability to quickly adapt designs and produce samples allows clients to innovate rapidly, accelerate time-to-market, and respond to emerging trends without long delays.

These production techniques not only foster high-quality end products but also offer a significant competitive advantage in the rapidly evolving sports equipment market.

For busy procurement managers, production delays and hidden costs can disrupt entire product rollout plans. NEX Padel stands out in terms of operational efficiency due to:

- Streamlined Processes: Our production facilities in Jiaxing, Zhejiang, utilize lean manufacturing methods5 and continuous process improvements. This approach minimizes waste and errors, ensuring that every batch of paddle rackets is delivered on schedule.

- Flexible Order Quantities: Whether you require a small batch for a niche market test or a full-scale production run, NEX Padel’s flexible manufacturing allows us to meet varying order sizes without compromising quality or efficiency.

- Cost-Effective Solutions: By optimizing our production supply chain and maintaining long-term relationships with high-quality material suppliers, we are able to offer competitive pricing. This is crucial for companies that must balance premium quality with budget constraints.

- Integrated After-Sales Support: In addition to manufacturing, NEX Padel provides ongoing support to ensure that any issues are promptly addressed. This level of service reduces downtime and enhances client satisfaction over the long term.

A streamlined production process not only minimizes delays but also reduces overall costs, providing significant advantages when establishing long-term procurement partnerships.

Several international brands have entrusted NEX Padel with their OEM production, validating our capabilities through real-world success stories. Consider the following data points and examples:

- Case Study 1: A renowned sports brand seeking to launch its unique line of padel paddles required a manufacturer capable of rapid prototyping and high-volume production. NEX Padel delivered a complete solution—customizing the paddle shapes and integrating advanced carbon fiber layers—all within the tight deadlines dictated by the market launch schedule.

- Case Study 2: Another client prioritized consistent quality for its premium product line. Through rigorous testing protocols and enhanced quality control, NEX Padel ensured that the manufactured paddles performed reliably under competitive conditions and met international standards, resulting in increased customer satisfaction and repeat orders.

Such case studies underline the tangible results produced by a manufacturer that consistently delivers on promise, bolstered by data and client testimonials. Using advanced production systems and comprehensive quality controls, NEX Padel has cemented its reputation as a top choice for businesses worldwide looking to source high-performance padel paddles.

After reviewing the technical details and real-world examples, procurement managers should consider the following action steps when deciding on an OEM padel paddle partner:

- Conduct a detailed technical evaluation comparing service providers on criteria such as material options, production techniques, available customizations, and delivery times.

- Request sample products and detailed case studies that demonstrate a manufacturer’s ability to meet your specific quality and performance requirements.

- Evaluate each potential partner’s capacity for both small batch and large-scale operations to ensure flexibility under different market conditions.

- Prioritize manufacturers with a proven track record of working with international brands, as this typically demonstrates adherence to high-quality standards and reliable delivery.

- Initiate direct discussions with technical and logistics experts from your shortlisted manufacturers to gain deeper insights into their production and quality assurance processes.

A thoughtful, data-driven approach to selecting an OEM partner ensures that your sourcing decisions lead to successful product rollouts, satisfied end-users, and a strong competitive edge in the sports equipment market.

In conclusion, the combination of advanced materials, technical expertise, and flexible production processes makes NEX Padel the ideal partner for companies seeking high-performance padel paddles. With strong credentials in customization, on-time delivery, and cost efficiency, NEX Padel is well-positioned to meet the evolving demands of global sports equipment brands. If your organization is ready to invest in quality and innovation, consider partnering with a manufacturer that puts precision engineering and customer requirements at the forefront of every project.

People Also Ask

Q: How does NEX Padel ensure high quality in OEM padel paddles?

A: NEX Padel uses advanced production techniques, rigorous quality control processes, and premium materials such as various grades of carbon fiber to ensure every paddle meets international performance and durability standards.

Q: What materials are commonly used in padel paddle production and what benefits do they offer?

A: High-performance padel paddles are typically made from fiberglass and different grades of carbon fiber (3k, 12k, 18k), which provide a balance between flexibility, strength, and power generation while ensuring overall durability.

Q: How does customization affect production turnaround times?

A: Customization at NEX Padel is supported by agile prototyping and streamlined processes, ensuring that even with bespoke designs, production remains efficient and turnaround times are minimized without compromising quality.

-

OEM/ODM manufacturer: Read the article to understand different manufacturing models where Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) strategies help streamline supply chains and product customization. ↩ ↩

-

advanced production techniques: Click to explore detailed methodologies and technologies that drive efficiency and precision in modern manufacturing, enhancing both quality and output. ↩ ↩

-

carbon fiber: Read the article to learn about the various grades and properties of carbon fiber and how they impact performance and durability in high-performance sports equipment. ↩ ↩

-

customized sports equipment: Discover how tailored design and personalization in sports gear can create competitive advantages and cater to niche market demands. ↩ ↩

-

lean manufacturing methods: Understand how lean principles reduce waste and improve production timelines while maintaining quality across manufacturing processes. ↩ ↩