Low carbon packaging offers a strategic solution for padel equipment brands looking to reduce environmental impact while maintaining cost efficiency and product quality. This article compares traditional versus low carbon packaging solutions, outlining key factors for procurement managers evaluating sustainable packaging technologies for padel rackets and accessories.

As the padel industry grows, manufacturers and brands face increasing pressure to improve sustainability. Traditional packaging methods often rely on materials that contribute to high carbon emissions1 and environmental waste. In contrast, low carbon packaging leverages eco-friendly materials2 and innovative design practices to reduce the overall carbon footprint3. For procurement managers and sustainable packaging specialists, adopting low carbon packaging means balancing cost, performance, and environmental impact while upholding brand reputation.

In today’s market, brands must navigate between conventional methods and greener alternatives. Below is a table comparing the core differences between traditional and low carbon packaging systems:

| Feature | Traditional Packaging | Low Carbon Packaging |

|---|---|---|

| Material Composition | Often relies on plastics and non-renewable fibers | Uses eco-friendly materials such as recycled paper, bio-plastics, and upcycled materials |

| Carbon Footprint | High due to fossil fuel-based production | Lower carbon emissions through sustainable practices |

| Cost | Generally lower upfront cost but with hidden environmental costs | Moderately priced with potential long-term savings through carbon credits and reduced waste disposal fees |

| Durability and Protection | Adequate for basic protection | Advanced materials ensuring protection while reducing weight |

| Customization | Limited design flexibility | High customization options in printing, shape, and functionality to reinforce brand identity |

| End-of-Life Disposition | Less recyclable, high landfill waste | Designed for recyclability and potential biodegradability |

This table highlights the key benefits of low carbon packaging innovation that align with the current global trend toward green manufacturing4.

The push for sustainable packaging solutions in the padel market is driven by several factors:

-

Environmental Regulations: Governments around the world are implementing stricter environmental policies. Brands that decide to upgrade to low carbon packaging not only comply with these regulations but also position themselves as industry leaders in sustainability.

-

Consumer Demand: Modern consumers are increasingly environmentally conscious. Eco-friendly packaging enhances brand perception and can be a decisive factor for customers seeking sustainable options.

-

Cost-Benefit Considerations: While the initial investment in low carbon packaging might be higher compared to traditional methods, cost savings over time through reduced waste and potential tax incentives offer a strong case for the transition.

-

Brand Reputation and Differentiation: Implementing green packaging technologies differentiates a brand in a highly competitive market. It reinforces a commitment to sustainability and can lead to stronger customer loyalty over time.

When considering low carbon packaging upgrades, procurement managers need to evaluate several critical factors:

The choice of material is paramount. Eco-friendly materials must not only reduce carbon emissions but also offer durability and excellent protective properties for padel equipment. Manufacturers often explore options like recycled plastics, bio-composites, and even natural fibers that ensure the packaging remains robust through transportation and handling.

In comparing traditional and low carbon packaging, a thorough cost analysis is essential. This analysis should account for:

- The initial investment in new materials and design.

- Long-term savings due to lower waste management costs and potential government incentives.

- The impact on overall brand value through improved consumer perception.

For padel brands like those partnered with NEX Padel, packaging is not just functional—it is also an extension of brand identity. Low carbon packaging solutions offer extensive customization options. From vibrant prints to tailored shapes that accommodate specific products (such as padel rackets, hand grips, and ball packages), these options allow brands to maintain their distinct identity even while shifting to sustainable materials.

Adopting low carbon packaging should include an evaluation of potential challenges:

- Supply Chain Integration5: How seamlessly can new materials be integrated with current production processes?

- Manufacturing Transition: What adjustments in machinery or workflow might be necessary to handle eco-friendly materials?

- Scalability: Can the new packaging solution be scaled to match growing demands as the brand’s portfolio expands?

Addressing these challenges with a clear plan is crucial for a smooth transition and long-term success in sustainable packaging.

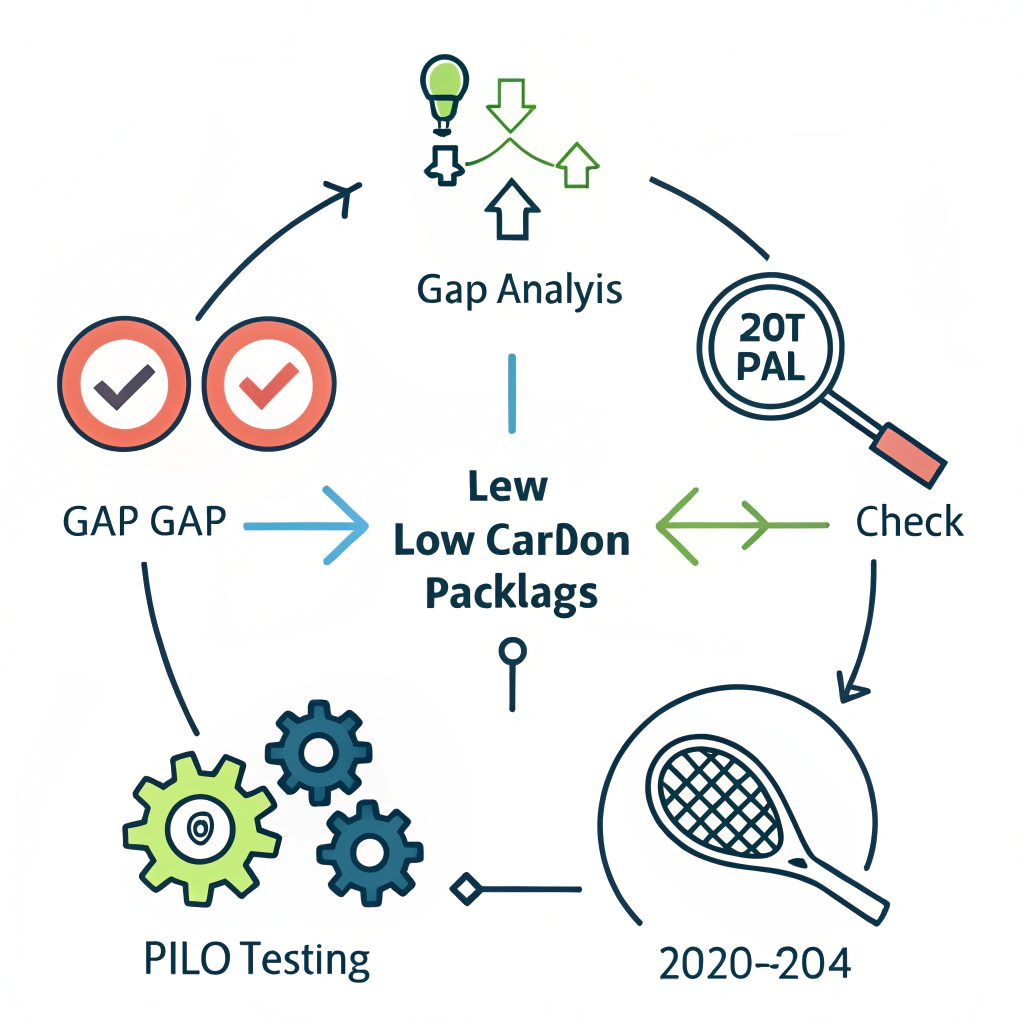

Companies transitioning to low carbon packaging should follow a structured approach:

Conduct an audit of existing packaging processes, identifying key areas where carbon emissions are highest. Analyze the material usage, waste production, and energy consumption patterns during production and disposal.

Partners like NEX Padel have hands-on experience with eco-friendly packaging innovations in the padel industry. Leveraging our manufacturing expertise can help tailor sustainable packaging solutions that meet both environmental and performance standards.

Before full-scale implementation, run pilot programs with selected packaging upgrades. Test for:

- Material Durability: Ensure the new design withstands distribution and handling.

- Consumer Acceptance: Collect feedback from retailers and customers regarding packaging aesthetics and functionality.

After implementation, track key performance indicators (KPIs) such as:

- Reduction in carbon footprint.

- Cost savings from decreased waste disposal and improved operational efficiency.

- Customer feedback and overall market response to the new packaging aesthetics.

Implementing these steps systematically can help mitigate risks and improve the overall transition process.

Consider a scenario where a leading padel equipment brand partnered with NEX Padel to shift from traditional packaging to a low carbon packaging solution. Initially, the company faced resistance due to perceived higher costs. However, by conducting a detailed cost-benefit analysis, they discovered that:

- Material Upcycling: Utilizing recycled carbon fiber and eco-friendly alternatives reduced costs over time.

- Brand Differentiation: Customizable packaging options improved customer engagement and loyalty.

- Environmental Impact: The shift led to a measurable decrease in carbon emissions throughout the supply chain.

The case study revealed that not only did the new packaging align with sustainability goals, but it also enhanced the overall perception of the brand as a leader in eco-friendly innovations.

When adopting low carbon packaging solutions, several best practices must be followed:

Quality control is critical in ensuring that eco-friendly materials perform at par with traditional packaging. Regular check-ups during production and post-production assessments guarantee that packaging remains durable and reliable.

Successful implementation often requires close collaboration between different teams such as procurement, manufacturing, and design. Working together ensures that all aspects—from material selection to final design—are optimized for both performance and sustainability.

Sustainable packaging is an evolving field. Brands must stay informed about the latest industry trends and technological advancements to continuously refine packaging solutions. Regular training sessions and workshops can help keep the team updated on best practices and new innovations.

Acquiring relevant environmental certifications can further validate the effectiveness of low carbon packaging solutions. Certifications act as a signal to consumers and industry stakeholders that the brand is committed to sustainable practices.

Transitioning to low carbon packaging in padel equipment manufacturing is not just an environmental imperative—it is a strategic move that can yield significant operational and market benefits. By understanding the differences between traditional and low carbon packaging, procurement managers can make informed decisions that balance quality, cost, and environmental impact.

Key actionable insights include:

- Conduct a comprehensive analysis of current packaging processes.

- Collaborate with experienced manufacturers like NEX Padel to leverage industry expertise.

- Undertake pilot projects to validate performance before committing to a full-scale roll-out.

- Invest in continuous monitoring and quality control to ensure sustainable practices are maintained.

Adopting low carbon packaging solutions is a forward-thinking strategy that aligns with global trends in environmental stewardship. Brands that successfully implement these innovations not only contribute to a greener future but also set themselves apart in a competitive market.

Q: What is the eco friendly padel racket?

A: Eco-friendly padel rackets are designed using sustainable materials, such as natural fibers and recycled components. For example, some manufacturers use a 100% natural flax fiber surface combined with advanced structural designs to improve durability and performance, making these rackets ideal for environmentally conscious players.

Q: Which is better carbon fiber or fibreglass padel racket?

A: Fibreglass padel rackets are recommended for beginners or those seeking a versatile, easy-to-handle option. On the other hand, carbon fiber rackets offer high performance with greater precision and power, making them suitable for advanced players who demand top-tier quality.

Q: Do carbon fiber paddles wear out?

A: With proper care, carbon fiber paddles can last over three years. Their lightweight, stiff, and powerful nature provides excellent feedback during play, but regular maintenance is important to sustain their performance over time.

-

carbon emissions: Reading this article will help you understand the key sources of CO2 produced in traditional manufacturing methods and their impact on the environment. ↩ ↩

-

eco-friendly materials: Reading this article will provide insights into sustainable material alternatives that reduce environmental impact while meeting performance standards. ↩ ↩

-

carbon footprint: Reading this article will explain how the total greenhouse gas emissions associated with products are measured and managed in a sustainable supply chain. ↩ ↩

-

green manufacturing: Reading this article offers an overview of eco-efficient production practices aimed at minimizing environmental waste and reducing resource consumption. ↩ ↩

-

Supply Chain Integration: Reading this article will detail strategies to align suppliers and production processes, ensuring a smooth transition to sustainable operations and improved overall efficiency. ↩ ↩