Selecting a reliable manufacturing partner such as NEX Padel can accelerate the scaling of your padel brand by ensuring high-performance production, product customization, and streamlined supply chain efficiency. In today’s competitive sports equipment market, a trusted manufacturing partner not only meets quality standards but also provides innovative solutions to help your brand stand out.

As the padel industry continues to expand rapidly, mid-level decision makers and brand managers are confronted with several challenges:

• Supply Chain Complexity: Balancing cost, quality, and timely delivery can be daunting when managing a growing padel product line.

• Customization Demands: Modern consumers expect unique designs with personalized touches, from custom prints to logos on hand grips and racket panels.

• Quality Assurance: Maintaining consistent high-quality products, ranging from glass fiber to advanced **12k or 18k carbon fiber1 materials, is essential to retain customer trust and meet performance expectations.

• Competitive Pressure: With major brands dominating the shelf space, breaking into the market and gaining recognition require strategic partnerships with proven manufacturers.

These challenges highlight why choosing a dedicated manufacturer like NEX Padel is a vital step in ensuring your brand’s scalability and competitive advantage.

When evaluating potential manufacturing partners, consider the following attributes:

• Quality Control and Consistency: A partner must have robust testing and quality assurance measures to produce rackets that meet performance standards consistently.

• Customization Capabilities2: The ability to offer full-scale customization—from racket shapes (Diamond, Round, Teardrop) to adjustments on hand grips and logos—enables your brand to deliver unique products.

• Advanced Production Techniques: Utilizing modern production techniques (such as precision molding3 and high-performance material integration) ensures durability and improved performance.

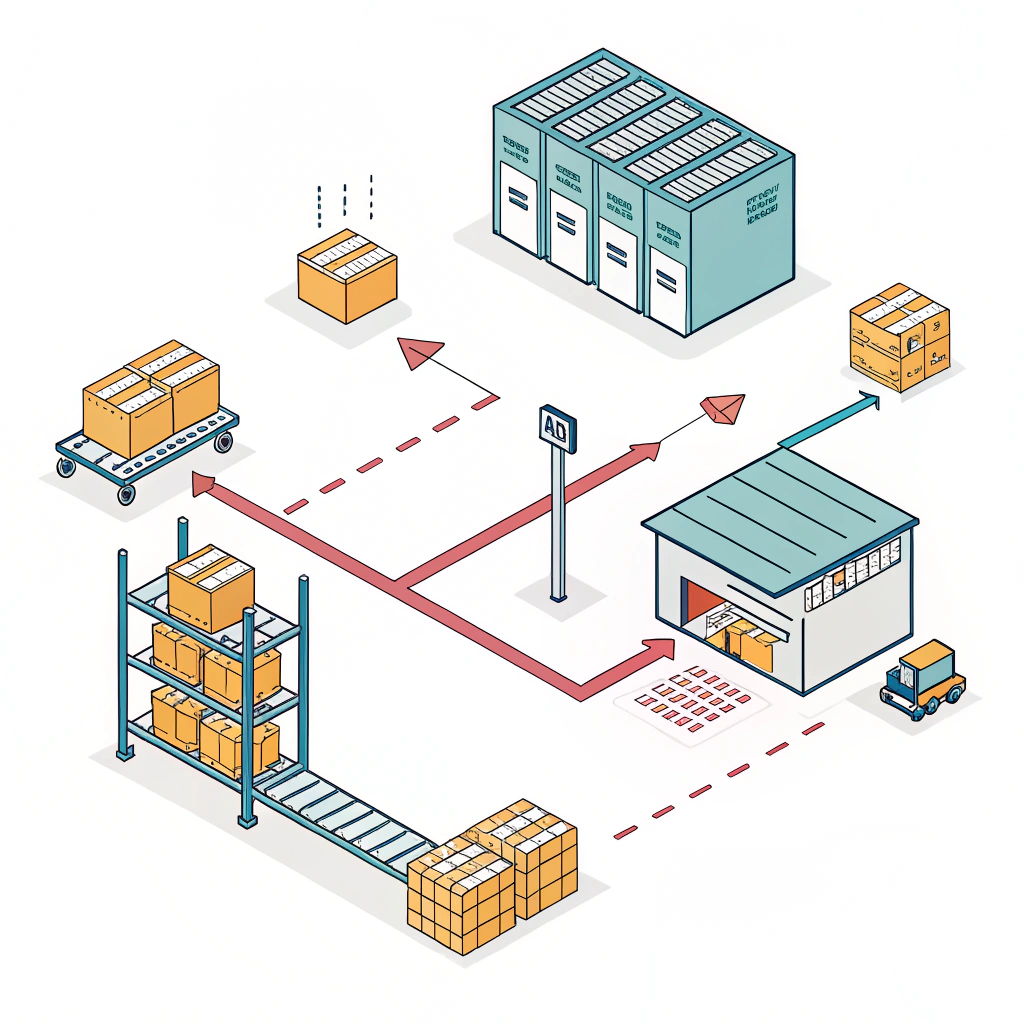

• Supply Chain Optimization4: Streamlined production and timely delivery minimize delays and reduce inventory costs, which is crucial for scaling your operations.

• Industry Experience and Reputation: A manufacturer with a track record of successful collaborations with global brands and deep industry insights can offer reliable support.

At NEX Padel, our offerings are tailored to meet the dynamic needs of padel brands seeking to expand their market presence. Our key capabilities include:

• Diverse Material Options: We work with materials ranging from glass fiber to premium 3k, 12k, and 18k carbon fibers to suit every performance requirement and price point.

• Rapid Prototyping5 and Fast Turnaround: Our design-to-production process is streamlined to allow quick sampling and fast delivery, ensuring you can react swiftly to market trends.

• Customization at Scale: We offer complete customization. Whether it’s the racket’s shape (Diamond, Round, or Teardrop), color schemes, print customization, or personalized hand grip designs, our production process is adaptable to your unique brand identity.

• Integrated Product Lines: Beyond rackets, we provide padel balls packaged in pressurized tubes, guaranteeing that the ball’s performance remains consistent with each use.

Effective supply chain management is essential for any brand looking to scale. Here’s how partnering with NEX Padel can optimize your operations:

- Simplified Inventory Management: Our advanced production planning reduces the need for excessive inventory, cutting storage costs and minimizing waste.

- Timely Production Cycles: With high efficiency in all manufacturing stages, we reliably meet production deadlines, allowing your brand to capitalize on seasonal demand peaks and market opportunities.

- Cost Efficiency: Leverage our established production processes and economies of scale to reduce per-unit costs without compromising quality.

- Transparent Communication: Continuous updates and a dedicated project manager keep you informed at every stage, ensuring alignment between your brand goals and production outcomes.

Below is a table that outlines specific benefits against common supply chain challenges:

| Challenge | How NEX Padel Addresses It | Benefit to Your Brand |

|---|---|---|

| Inconsistent quality | Rigorous quality control protocols | Builds consumer trust and brand reputation |

| Production delays | Efficient production planning | Ensures timely market supply |

| Limited customization options | Advanced flexible manufacturing processes | Offers unique product differentiation |

| High inventory costs | Optimized production cycles | Reduces overheads and improves cash flow |

Beyond manufacturing excellence, a successful padel brand also relies on a well-rounded approach to business strategy. Consider these action points:

• Market Segmentation and Positioning: Identify target segments (e.g., premium competitive players vs. recreational players) and adapt product specifications to meet their preferences.

• Collaborative Product Innovation: Engage in continuous dialogue with your manufacturing partner to explore material innovations, technological upgrades, and design enhancements that keep your brand ahead of market trends.

• Integrated Branding and Packaging: Enhance your product’s appeal using customized packaging that resonates with your brand ethos. Our ability to customize not only the racket but also associated components like hand grip and cover labels ensures a cohesive brand experience.

• Data-Driven Decision Making: Utilize market research and performance analytics provided by your manufacturing partner to adjust production volumes, refine design elements, and make proactive decisions based on real-time trends.

Many of our partners have experienced significant improvements in market share and brand influence through collaborations with NEX Padel. For example:

• Brand A – Expanding Product Lines: By partnering with us, Brand A was able to swiftly introduce a new line of high-performance rackets with bespoke design features, resulting in increased consumer engagement and a notable boost in sales.

• Brand B – Improved Time-to-Market: Streamlining production cycles and leveraging our rapid prototyping capabilities allowed Brand B to reduce time-to-market by over 30%, providing a competitive edge during peak seasons.

• Brand C – Cost Optimized Production: Through supply chain optimization and consistent quality control, Brand C achieved significant reductions in per-unit manufacturing costs while maintaining superior performance.

These examples showcase the transformative impact of aligning with a manufacturer that not only understands the technical aspects of padel racket production but also keeps pace with industry trends and consumer demands.

Even with a reliable partner, challenges may arise in scaling your padel brand. Here are common obstacles and strategies to address them:

• Fluctuating Demand: Implement flexible production schedules and maintain open communication channels to adjust production volumes as needed.

• Quality Consistency: Regularly conduct quality audits and work closely with your manufacturing partner to fine-tune quality control measures.

• Technological Adaptability: Invest in continuous R&D and encourage collaborations for technology integration, such as improved carbon fiber production techniques.

• Market Volatility: Rely on industry data and trend analysis to forecast demand accurately, ensuring that production aligns with consumer behavior and seasonality.

By anticipating these obstacles, you can work proactively with your manufacturing partner to ensure smooth operations and maintain customer satisfaction.

In summary, selecting a dependable manufacturing partner like NEX Padel is crucial for successfully scaling your padel brand. From innovative production techniques to a diverse range of customizable products, a reliable partner provides the foundation for competitive differentiation and operational efficiency. Emphasizing quality, customization, and supply chain excellence not only enhances product offerings but also positions your brand for long-term success in a rapidly growing market.

Take the next step today by evaluating your current manufacturing strategy and considering how a strategic partnership can drive growth, innovation, and improved profitability.

• What brand makes the best padel rackets?

Several top brands in the padel racket market focus on performance, design, and innovative materials. While numerous leading brands exist, the emphasis should be on finding a manufacturing partner that can deliver customized, high-quality products that elevate your brand’s reputation.

• Do expensive padel rackets make a difference?

Not necessarily. More expensive padel rackets often feature smaller sweet spots and firmer materials, which might be less suitable for beginners or intermediate players. The key is to match the equipment’s design and performance attributes with the target player’s skill level and preferences.

• Is the business of padel a good one?

Absolutely. Padel is one of the fastest-growing sports worldwide, with millions of enthusiasts. This rapid growth offers significant opportunities for businesses looking to expand their product lines and enter new markets within the sports equipment industry.

-

carbon fiber: Click to read an article explaining the benefits and applications of carbon fiber in high-performance manufacturing, including its strength-to-weight ratio and durability. ↩ ↩

-

Customization Capabilities: Click to understand how advanced customization capabilities can help tailor products to specific market needs and drive brand differentiation. ↩ ↩

-

precision molding: Click to learn more about precision molding techniques that ensure high tolerances and uniform quality in modern manufacturing processes. ↩ ↩

-

Supply Chain Optimization: Click to explore strategies and best practices for optimizing supply chain management to reduce delays and cut operational costs. ↩ ↩

-

Rapid Prototyping: Click to discover how rapid prototyping accelerates product development by allowing quick iterations and fast turnaround times. ↩ ↩