Quick answer: Choose a padel handle by balancing grip size (circumference and length), handle core density (vibration damping vs feedback), and grip material (EVA, PU, leather, perforated or tacky synthetics). For OEM specs, request exact circumference (mm), length (mm), tolerances (±0.5 mm), core Shore A hardness1, overgrip type and adhesive method. Ask the supplier for three prototypes (small/medium/large), run defined slip and durability tests, and finalize based on play-style targets (control vs power) and manufacturing constraints such as tooling and MOQ2.

Why this matters for procurement

- A wrong handle choice reduces player comfort, increases injury risk (epicondylitis), and harms perceived quality.

- For brands and OEMs, handle specs drive tooling cost, assembly steps (overgrip, shrink-wrap, butt cap fit), and return rates.

- You need clear, measurable specs to compare suppliers and to validate samples—subjective descriptions (“more tacky”, “softer”) are not enough.

Key variables to specify (the procurement checklist)

- Handle circumference — the grip perimeter around the handle (mm). Primary determinant of fit.

- Handle length — distance from end of butt cap to throat (mm). Affects two-handed backhands and leverage.

- Handle core density / Shore A hardness — defines damping vs control.

- Grip material — EVA, PU, leather, perforated, or specialized tacky synthetic.

- Surface finish & perforation — affects sweat wicking and tack.

- Butt cap design — shape, logo, locking method (snap vs adhesive).

- Assembly & packaging — overgrip type, shrink-wrapping, tube packing for rackets.

- Tolerances & tests — dimensional tolerances, slip resistance, peel adhesion, aging.

Core recommendation summary (one-line)

- For control-oriented players: smaller circumference (100–105 mm), shorter to medium length (100–105 mm), core Shore A 50–65, medium tack PU or thin leather overgrip.

- For power-oriented players: slightly larger circumference (105–110 mm), standard length (105–110 mm), firmer core Shore A 60–70, thicker overgrip for stability.

- For players with wrist/elbow issues: softer core Shore A 30–45, perforated EVA overgrip for sweat control.

Detailed comparison: material and performance

| Material | Tack / Grip Feel | Vibration Damping | Durability | Cost | Best for |

|---|---|---|---|---|---|

| EVA (soft foam) | Low–Medium (depends on cover) | High (good damping) | Medium | Low | Players needing shock absorption; budget lines |

| PU (synthetic) | Medium–High (good tack) | Medium | High | Medium | Most OEMs—balanced feel for control & durability |

| Leather (real) | Medium (slicker, breaks in) | Low | High (if maintained) | High | Premium lines, classic feel |

| Tacky synthetic (polymer blends) | High | Medium–Low | Medium | Medium–High | Tournament players prioritizing grip |

| Perforated variants | Improved sweat wicking | Depends on core | Similar to base material | +Small cost | Hot climates, sweaty players |

Notes:

- Perforation improves sweat transfer and reduces slippage in humid conditions.

- Overgrip thickness adds about 1–2 mm to circumference—specify whether measurement is with or without overgrip.

Handle geometry: length, circumference and shape

- Circumference (perimeter) vs diameter: suppliers sometimes specify diameter—ask for perimeter in mm or equivalent grip size (e.g., tennis L1-L5). Use perimeter for clarity.

- Typical padel handle lengths: 100 mm, 105 mm, 110 mm are common. Longer handles give more leverage; shorter handles improve wrist action. Specify exact mm.

- Shape: round vs slightly oval/ergonomic—oval options orient the racket in hand and help for repeatable grips but require consistent manufacturing tolerances to prevent rotation.

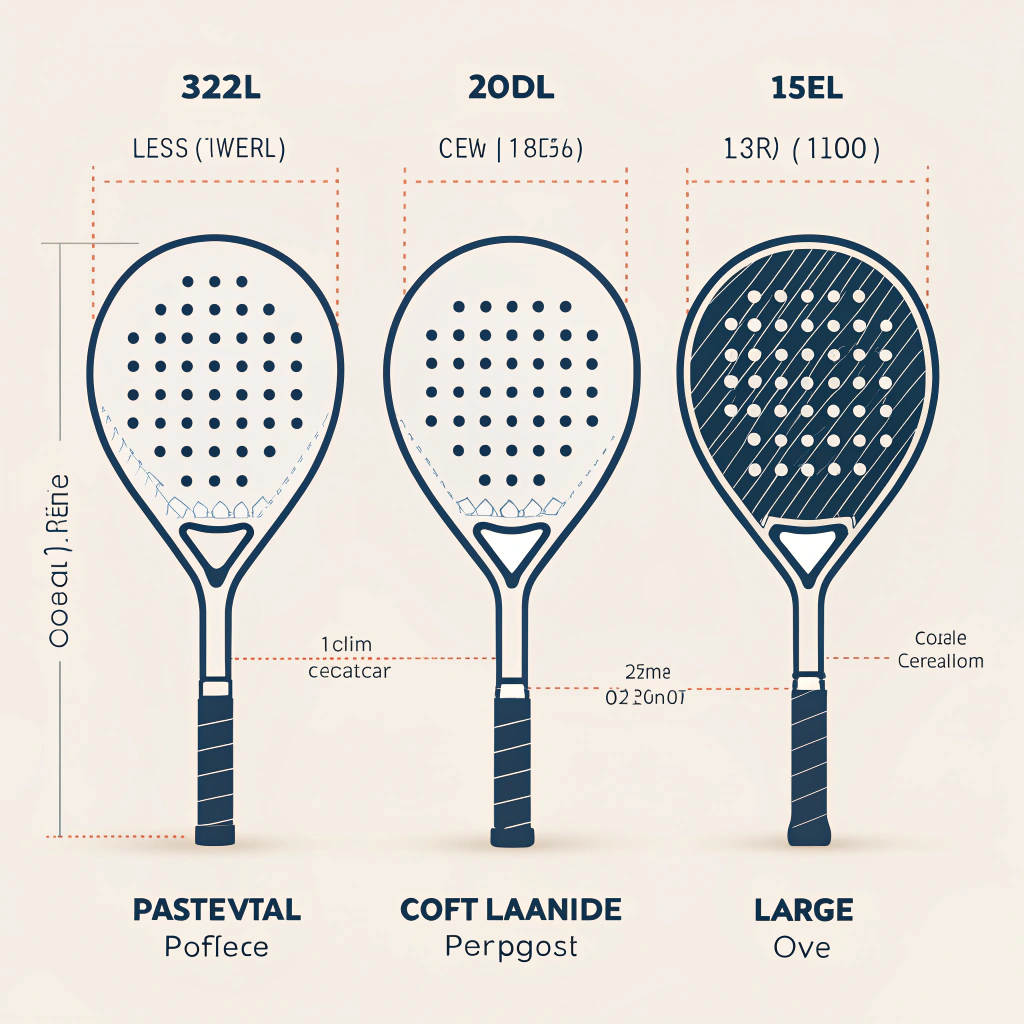

Recommended dimension table (for OEM decision)

| Player hand size (measure from base of palm to tip of middle finger) | Circumference (mm) | Handle length (mm) | Overgrip allowance |

|---|---|---|---|

| Small (<180 mm) | 98–102 | 100 | +1–2 mm |

| Medium (180–200 mm) | 103–108 | 105 (standard) | +1–2 mm |

| Large (>200 mm) | 109–114 | 105–110 | +1–2 mm |

Tolerances: specify manufacturing tolerance for circumference ±0.5 mm, length ±1 mm; ovality/eccentricity <0.5 mm.

Core density and vibration damping: measurable specs

- Ask for Shore A hardness for the handle core or core EVA (typical ranges 25–70). Example guidance:

- Softer core (Shore A 25–40): better vibration damping, less feedback—suits recreational players or those with elbow issues.

- Medium (Shore A 40–55): balanced feel—most OEM target.

- Firm (Shore A 55–70): more direct feedback, more durable—used in power models.

- Tolerance: ±2 Shore A units.

- Supplier test: request DMA (dynamic mechanical analysis)3 or simple impact-vibration test (accelerometers) where the handle attenuates measured vibration amplitude by X% compared to a reference handle.

Manufacturing & assembly constraints (what affects cost & lead time)

- Custom butt caps and molded cores increase tooling cost (aluminum molds). Typical tooling lead time: 2–4 weeks; tooling cost depends on complexity.

- Custom core densities might need new mixing runs; MOQ2 may apply (ask supplier).

- Overgrip customization (color/print/perforation) adds lead time but low cost. Shrink-wrapping and pre-wrapping increase labor but improve retail readiness.

- Tolerances tighter than ±0.5 mm add inspection time and reject rates. Confirm acceptable reject rate and rework policy.

Testing protocols you should require for sample validation

- Dimensional check: circumference (mm), length (mm), ovality. Use vernier calipers, circumference tape. Acceptance ±0.5 mm.

- Slip resistance test: measure static friction coefficient using ASTM D18944-style rig or handheld force gauge. Target: static friction ≥ 0.6 for tacky grips when dry; ≥0.4 when simulated-sweat.

- Tack retention after cycles: perform 1,000 wrap/unwrapping cycles and measure tackiness reduction (%).

- Sweat and abrasion test: 24-hour synthetic sweat exposure + 5,000 abrasion cycles using standard rub tester—look for material degradation, color bleed, or tack loss.

- Peel adhesion for overgrip and taped joints: 90° peel test per ASTM D33305—ensure adhesive force meets spec.

- Vibration test: impact to racket head while measuring acceleration at handle; compare attenuation to baseline handle.

- Durability/climate aging: 72-hour heat and humidity chamber followed by functional checks.

- Play test: 20 players across skill levels record comfort, slippage, and preferred feel. Use structured survey (Likert scale) and capture hand size.

Require test reports with each prototype batch. Specify acceptance criteria numerically.

Cost & timeline guidance (example for RFQ)

- Prototype samples (3 variations: small/medium/large): typical cost USD 50–150 per sample depending on customization. Lead time: 7–14 days if molds exist; 14–28 days for new parts.

- Tooling: custom butt cap or core mold USD 500–2,500 depending on complexity.

- MOQ: 500–2,000 units common for custom colored grips; 1,000+ for full custom racket assemblies (depends on supplier). NEX Padel offers flexible sampling and supports full customization—ask about batch discounts and bundling grips with rackets to reduce per-unit cost.

- Quality inspection: budget 0.5–1% of order value for third-party inspection.

Actionable RFQ checklist to send to suppliers (copy-paste)

- Product: Padel racket handle + overgrip specification

- Circumference: ___ mm (state with/without overgrip) ±0.5 mm

- Length: ___ mm ±1 mm

- Core material & Shore A hardness: material = EVA/PU, hardness = __ (±2)

- Grip material: PU / EVA / leather / perforated / tacky-synthetic (specify color & finish)

- Butt cap: model drawing + logo vector + attachment method

- Surface finish: matte / glossy / anti-slip coating / perforation pattern (specify)

- Assembly: overgrip type, shrink-wrapping, packaging per unit

- Tests required: dimensional, slip coefficient, tack retention, peel adhesion, durability, vibration attenuation (specify standards and acceptance limits)

- Samples: request 3 prototypes (small/medium/large) and lead times

- MOQ & FOB price tiers, tooling costs, sample costs, payment terms

Practical buyer tips & trade-offs

- If you need fast time-to-market, standard cores and existing butt cap molds reduce lead time and upfront cost.

- Prioritize user comfort and slip resistance for consumer brands; prioritize durability for rental/club equipment.

- When in doubt, order three prototypes covering the small/medium/large spectrum and run the same test protocol across them. Make go/no-go decisions based on measured slip and tack retention, not just player feel.

Conclusion — an operational plan (next steps)

- Finalize target player profile (control/power/recreational) and intended retail price.

- Prepare RFQ using the checklist above and send to 2–3 vetted suppliers (include NEX Padel).

- Request three prototypes with full test reports and defined acceptance criteria.

- Run lab and field tests in parallel (mechanical and 20-player play tests).

- Approve production when prototypes meet dimensional, slip and durability thresholds, and after negotiating tooling & MOQ.

People Also Ask

Q: What is the 40-40 rule in padel?

A: The 40-40 rule (deuce) in padel is decided by a single point called the golden point: when the score reaches 40-40, the next rally determines the game winner instead of playing advantage points. This keeps matches faster and creates decisive moments.

Q: How to improve grip on a padel racket?

A: Improve grip by keeping grips clean and replacing overgrips regularly. Choose an overgrip material suited to sweat conditions (perforated for high sweat), use tack-enhancing materials like PU or tacky synthetics, and ensure the handle circumference matches the player. For immediate improvement, change to a tackier overgrip and clean the handle surface before play.

Q: How hard should you grip a padel racket?

A: Default grip tension should be relaxed—enough to feel control while allowing wrist movement. Tighten grip briefly for blocking shots and loosen for touch shots. For testing and ergonomics, observe grip force ranges: light hold for volleys and drop shots; increased force for defensive blocks and power smashes.

-

Shore A hardness: Reading about Shore A hardness helps you translate subjective feel into a measurable spec—how soft vs. firm the core is, typical ranges used in rackets, and acceptable tolerances. This lets procurement set numeric targets (e.g., Shore A 50–65) and compare supplier data sheets and test reports rather than relying on vague terms like “soft” or “firm.” ↩ ↩

-

MOQ: Understanding Minimum Order Quantity (MOQ) clarifies price breaks, inventory planning, tooling amortization, and sampling strategy. A supplier’s MOQ drives RFQ decisions (e.g., whether to accept color variants or request pooled runs) and affects unit cost and lead time—critical for buyer negotiations. ↩ ↩ ↩2

-

DMA (dynamic mechanical analysis): DMA is a lab method that quantifies viscoelastic behavior (storage/loss modulus, damping) across frequency/temperature ranges. Reading up on DMA explains why it’s a superior, repeatable way to specify handle damping and to validate supplier claims about vibration attenuation. Ask for DMA plots or equivalent metrics when comparing cores. ↩ ↩

-

ASTM D1894: This standard method for measuring coefficient of friction shows how to produce repeatable slip-resistance data (dry and simulated-sweat). Specifying ASTM D1894-style tests in RFQs ensures suppliers deliver comparable friction numbers you can use as pass/fail criteria for grip tackiness. ↩ ↩

-

ASTM D3330: ASTM D3330 defines 90° peel adhesion testing for tapes and adhesives. Referencing this standard helps you set numeric peel-strength acceptance limits for overgrips and taped joints, ensuring durability of assembled handles and consistent supplier test reports. ↩ ↩