In brief, sourcing high-performance padel rackets from China provides procurement managers1 with cost-effective, customizable, and meticulously engineered solutions. Chinese manufacturers such as NEX Padel offer rapid prototyping2, advanced carbon fiber3 options, and rigorous quality controls4 designed to meet the specific demands of global sports equipment distributors.

Procurement managers and sourcing specialists in the sports equipment industry are continually pressed to balance quality, price, and delivery timelines when selecting suppliers. In today’s competitive market, particularly in high-performance padel equipment manufacturing, suppliers must offer not only innovative materials and design flexibility but also proven reliability and consistent product quality. This guide delves into the key aspects of sourcing padel rackets from China and explains how partnering with established manufacturers like NEX Padel can fulfill these requirements.

One of the most common challenges in sourcing padel rackets involves finding a supplier that meets stringent quality standards while offering competitive pricing. Procurement managers often face issues such as:

• Inconsistent product quality due to varying production standards

• Limited customization options with some suppliers

• Inadequate communication and delivery delays

• Complex supply chain logistics5 and after-sales support

These concerns necessitate thorough due diligence and a clear understanding of the production process. Assessing the manufacturing capabilities, material choices, and quality control strategies is essential in overcoming these challenges and ensuring that the final product meets both performance and aesthetic expectations.

China has long been recognized as a global production hub, especially for sports equipment. Several factors contribute to its competitive advantage when it comes to high-performance padel rackets:

- Advanced Production Techniques: Modern factories leverage state-of-the-art machinery and refined production processes to achieve precision and consistency.

- Diverse Material Options: From traditional fiberglass to multiple grades of carbon fiber—3K, 12K, and 18K—manufacturers like NEX Padel offer materials to suit every performance requirement.

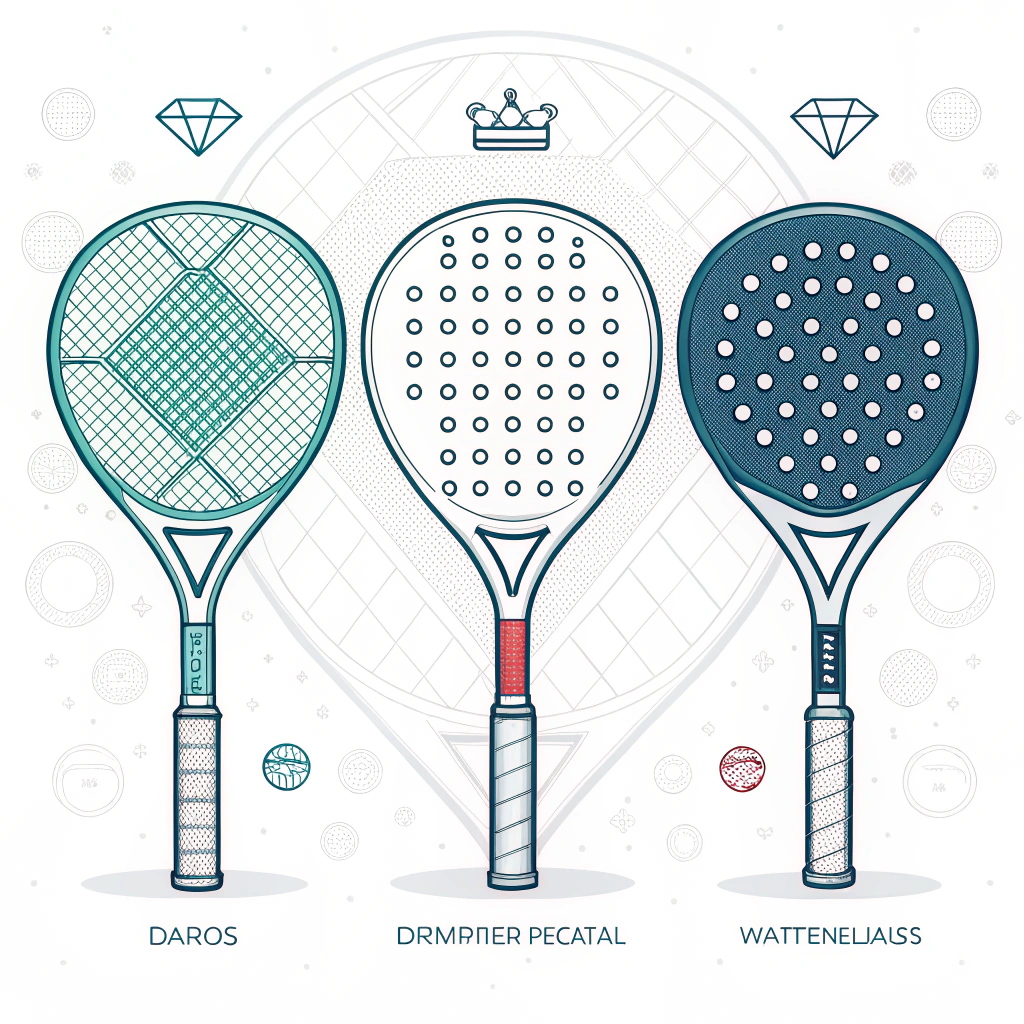

- Customization Capability: Their ability to produce custom shapes (Diamond, Round, and Teardrop) and offer tailored design solutions, including custom colors and printing, ensures that the product stands out in the market.

- Rapid Prototyping & Quick Turnaround: Fast sample production and short lead times help procurement managers meet market demands swiftly.

- Cost Efficiency: Leveraging economies of scale, Chinese manufacturers can offer competitive pricing without compromising the production quality.

Successfully sourcing padel rackets involves a step-by-step analysis of your supplier options. Below is a detailed breakdown of the sourcing process based on real-world supply chain experience:

When evaluating a supplier, procurement managers should consider the following:

| Evaluation Criteria | Key Considerations |

|---|---|

| Production Capacity | Can the supplier handle high-volume orders without compromising quality? |

| Material Quality | Does the factory use premium-grade materials such as 3K, 12K, or 18K carbon fiber? |

| Customization & Design | Are the customization options extensive, including shapes, color prints, and logo incorporation? |

| Quality Control Measures | What rigorous testing and quality protocols are in place before shipment? |

| Lead Times & Delivery | How quickly can they deliver orders and manage potential supply chain disruptions? |

| Pricing & Cost Transparency | Is the pricing competitive and reflective of the quality and customization offered? |

For high-performance padel rackets, material selection is crucial. The options range from flexible fiberglass to advanced, rigid carbon fiber variants. Understanding these material differences can significantly impact the racket’s performance:

• Fiberglass: Offers flexibility and is suitable for entry-level products.

• Carbon Fiber (3K, 12K, 18K): Provides superior strength-to-weight ratios, improved durability, and enhanced control on the court. Greater fiber count (e.g., 18K) typically delivers increased strength and stiffness, benefiting competitive players who demand precision.

Procurement managers should align the material selection with the intended market segment to ensure both functionality and cost considerations are met.

Customization is a key factor that distinguishes successful suppliers in the padel racket market. Beyond simply adjusting the racket’s shape, customization includes:

• Shape Customization: Available shapes include Diamond, Round, and Teardrop, each offering unique balance and performance attributes.

• Color and Print Options: Custom printing allows brands to reflect their corporate identity, enhancing brand visibility in a competitive market.

• Additional Accessories: Elements such as hand grips and handle covers can be customized to incorporate logos or specific design features, further tailoring the product to customer needs.

Such flexible manufacturing capabilities allow procurement managers to cater effectively to diverse market segments, ensuring that the final product resonates with various buyer demographics.

Maintaining high standards throughout the production process is vital. Chinese suppliers like NEX Padel invest heavily in quality control systems to monitor every stage—from material selection to final assembly. Key quality assurance strategies include:

• Regular Inspections: Routine checks at multiple production stages help identify and address potential defects early.

• Advanced Testing Methods: Utilizing state-of-the-art testing equipment and methodologies ensures that each racket meets performance standards.

• Supplier Audits: Regular internal and third-party audits verify the consistent application of quality practices and compliance with international standards.

• Traceability: Integrating data tracing systems through production phases enables quick identification and resolution of any issues that occur during manufacturing.

For procurement managers, these measures translate into reduced risk and assurance that the delivered products will perform consistently in the field.

NEX Padel has emerged as a leading manufacturer, trusted not only for its high-quality padel rackets but also for its tailored approach to meeting customized requirements, rapid turnaround times, and strong client relationships. Consider the following case study:

A major sports equipment distributor sought to expand its padel racket portfolio with products that were not only durable but also offered exceptional design flexibility. After evaluating multiple suppliers, they partnered with NEX Padel. Key outcomes included:

• A detailed initial consultation ensured that the distributor’s performance expectations and design ideas were clearly understood.

• Rapid prototyping of customized Diamond, Round, and Teardrop shape rackets, utilizing advanced carbon fiber technology.

• Strict quality control protocols resulted in a product that adhered to internationally recognized standards, with no returns or defects reported during the critical launch phase.

• The distributor benefited from a transparent pricing strategy and reliable delivery timelines, enhancing their market competitiveness.

This case clearly illustrates how thorough supplier assessment, combined with advanced production techniques and strong quality management, can culminate in a successful sourcing outcome that bolsters brand trust and customer satisfaction.

To ensure a successful sourcing experience when selecting a padel racket manufacturer, consider the following steps:

- Conduct Comprehensive Research: Initiate detailed market research to shortlist potential suppliers. Focus on manufacturers with a solid track record in high-performance sports equipment.

- Request Samples and Prototypes: Evaluate sample products to verify material quality, design accuracy, and performance standards before committing to large orders.

- Assess Customization Options: Verify that the supplier can meet specific customization needs, including specialized shapes, colors, and accessory customization.

- Review Quality Assurance Protocols: Confirm that the manufacturer employs robust quality controls and possesses relevant certifications or third-party audit records.

- Negotiate Terms Clearly: Discuss pricing, delivery timelines, and after-sales support in detail to avoid unexpected challenges later in the supply chain.

- Factor in Communication and Support: Ensure that there is a dedicated team for addressing inquiries and managing the order process, which significantly reduces the risks associated with international sourcing.

Following these recommendations will reduce procurement risks and ensure that the final product meets both market demands and quality expectations.

Sourcing high-performance padel rackets from China, particularly when working with established manufacturers like NEX Padel, offers a strategic advantage in terms of production quality, cost efficiency, and customization capabilities. This guide has explored the critical steps—from supplier evaluation and technical material analysis to quality control measures and case study insights—providing procurement managers with a comprehensive framework for informed decision-making. With robust production capabilities and tailored manufacturing solutions, Chinese suppliers can be trusted partners in fulfilling the growing demand for advanced sports equipment.

By leveraging these insights, procurement managers can confidently navigate the sourcing process, ensuring that the padel rackets align with both performance standards and market expectations. Now is an opportune time to invest in reliable, high-performance manufacturing partnerships that guarantee both quality and efficiency.

Q1: How do I evaluate high-performance padel racket suppliers in China?

A1: Evaluate suppliers based on their production capacity, material quality (such as carbon fiber variants), customization options, quality control measures, lead times, and transparent pricing.

Q2: What material options should be considered for padel rackets?

A2: The primary materials include fiberglass for entry-level products and advanced carbon fiber variants (3K, 12K, and 18K) for high-performance rackets. Carbon fiber offers better strength-to-weight ratios, durability, and control.

Q3: How can customization enhance the market appeal of padel rackets?

A3: Customization options, including different shapes (Diamond, Round, and Teardrop), color prints, and accessory options like custom hand grips, allow brands to differentiate their products, align with market demands, and boost overall brand visibility.

-

[procurement managers]: Click to learn more about the role of procurement managers in sourcing strategies, their responsibilities, and how they contribute to efficient supply chain operations. ↩ ↩

-

[rapid prototyping]: Click to explore the concept of rapid prototyping, its importance in reducing product development time, and its impact on manufacturing innovation. ↩ ↩

-

[carbon fiber]: Click to understand the properties of carbon fiber, including the differences between 3K, 12K, and 18K variants, and their applications in high-performance sports equipment design. ↩ ↩

-

[quality controls]: Click to read about the various quality control measures implemented in manufacturing processes to ensure product consistency, compliance, and reliability. ↩ ↩

-

[supply chain logistics]: Click to gain insights into supply chain logistics, including planning, coordination, and optimization techniques essential for managing global manufacturing and distribution networks. ↩ ↩