In short, this guide compares the three primary padel racket shapes—Round, Teardrop, and Diamond—by examining how each design influences performance, material selection, and customization options. This summary enables procurement managers and product developers to quickly assess which shape fits their market needs and technical requirements.

In today’s competitive sports equipment market, particularly in the padel industry, the shape of the racket plays a crucial role in defining player performance and influencing manufacturing considerations. As a procurement or product development manager, you need to decide between three top designs: Round, Teardrop, and Diamond. Each offers unique benefits and trade-offs that affect balance, power, control, and customization ease.

At NEX Padel, we recognize these nuances because our manufacturing expertise spans multiple carbon fiber variants1 and customization options2. From 3k, 12k, to 18k carbon fibers, our production techniques ensure that each product meets high-performance standards while remaining tailored to our clients’ technical and market demands.

Before diving deep, here is a concise overview of the three padel racket shapes:

- Round Shape: Emphasizes control and maneuverability, typically appealing to players seeking a balanced performance.

- Teardrop Shape: Offers a balance of power and control, providing a compromise solution that appeals to both technical and power players.

- Diamond Shape: Prioritizes power and aggressive play, usually preferred by players aiming for a more offensive style.

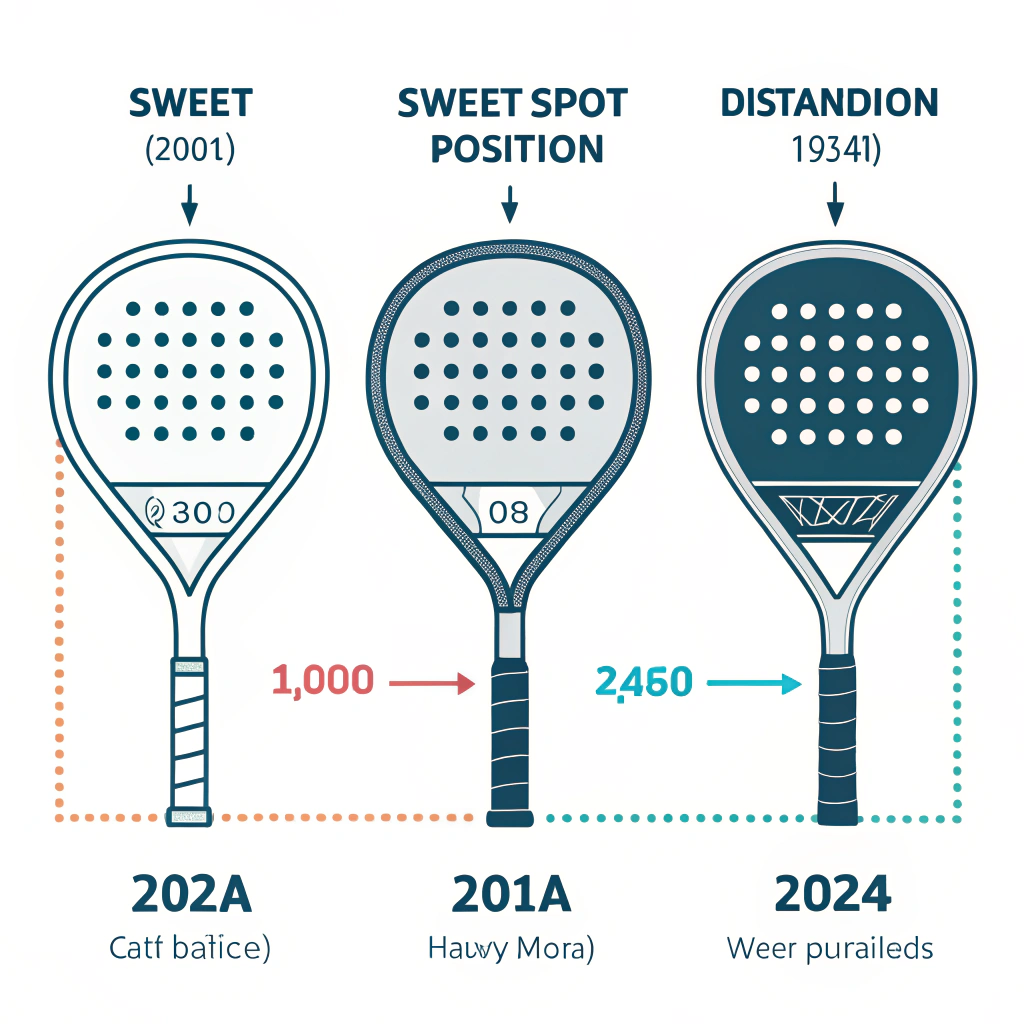

Each design inherently affects the racket’s balance point, sweet spot location, and even the manufacturing techniques required. These factors influence how the racket performs on the court and how easily it can be customized.

Round-shaped rackets are traditionally the most popular choice among players who value control. Their design features a wider head with a lower center of gravity, which shifts the playing weight towards the handle. This distribution provides benefits such as:

- Enhanced Control: Ideal for players who rely on precise ball placement.

- Maneuverability: The balanced weight distribution means easier handling, which is crucial during rapid exchanges.

- Ease of Manufacturing: The symmetric design allows for a simple manufacturing process, which can reduce production costs without sacrificing quality.

However, this design typically results in a smaller sweet spot. This means that while precision is maximized, there might be a slight compromise on power output. Despite this, many top padel brands favor the round design for its consistency and the well-known performance that it offers.

Teardrop-shaped rackets blend the characteristics of round and diamond shapes, making them popular among a broader player base. They are engineered to provide a harmonious mix of control and power:

- Balanced Performance: The overall design shifts the sweet spot slightly upward, yielding additional power without losing much control.

- Improved Stability: The asymmetrical design can sometimes better support off-center hits.

- Manufacturing Considerations: While this shape requires more refined engineering than the round shape, advanced CNC3 and molding techniques have made production both routine and economical.

This design is especially beneficial when players require flexibility in their game, offering a middle-ground solution that works for both defensive and offensive play styles.

Diamond-shaped rackets are typically designed to maximize power output, catering to a niche market of aggressive and power-driven players:

- Enhanced Power: The design naturally shifts the balance point further away from the handle, increasing racket swing speed and impact power.

- Offensive Play: Players employing an aggressive style prefer the diamond shape due to its power-centric construction.

- Customization Challenges: The non-traditional shape requires more sophisticated manufacturing techniques, which may lead to higher production costs. Special attention must be given to material distribution, especially when using high-grade carbon fibers such as 12k and 18k.

While the diamond shape offers tremendous offensive potential, it tends to reduce control, making it ideal solely for players who can compensate with excellent technique and physical strength.

The following table provides a side-by-side comparison of key performance and manufacturing factors for each racket shape:

| Attribute | Round Shape | Teardrop Shape | Diamond Shape |

|---|---|---|---|

| Performance Focus | Balance, Control | Balance of Power & Control | Power, Offensive Play |

| Sweet Spot Location | Centered, Lower | Slightly Above Center | Higher, more forward |

| Weight Distribution | Uniform, favoring control | Mixed, balanced distribution | Head-heavy, power-oriented |

| Manufacturing Complexity | Low (symmetric design) | Medium (asymmetrical design) | High (requires precision) |

| Cost Considerations | Economical production | Moderate costs | Higher production costs |

| Target Audience | Beginners/Intermediate players | Versatile, all-around players | Advanced/aggressive players |

| Customization Options | Standard and extensive | Highly customizable | Fully customizable, premium |

This table is meant to guide procurement managers in quickly assessing which racket shape aligns with their product strategy and target market. It emphasizes the trade-offs between control and power, manufacturing ease, and cost efficiency.

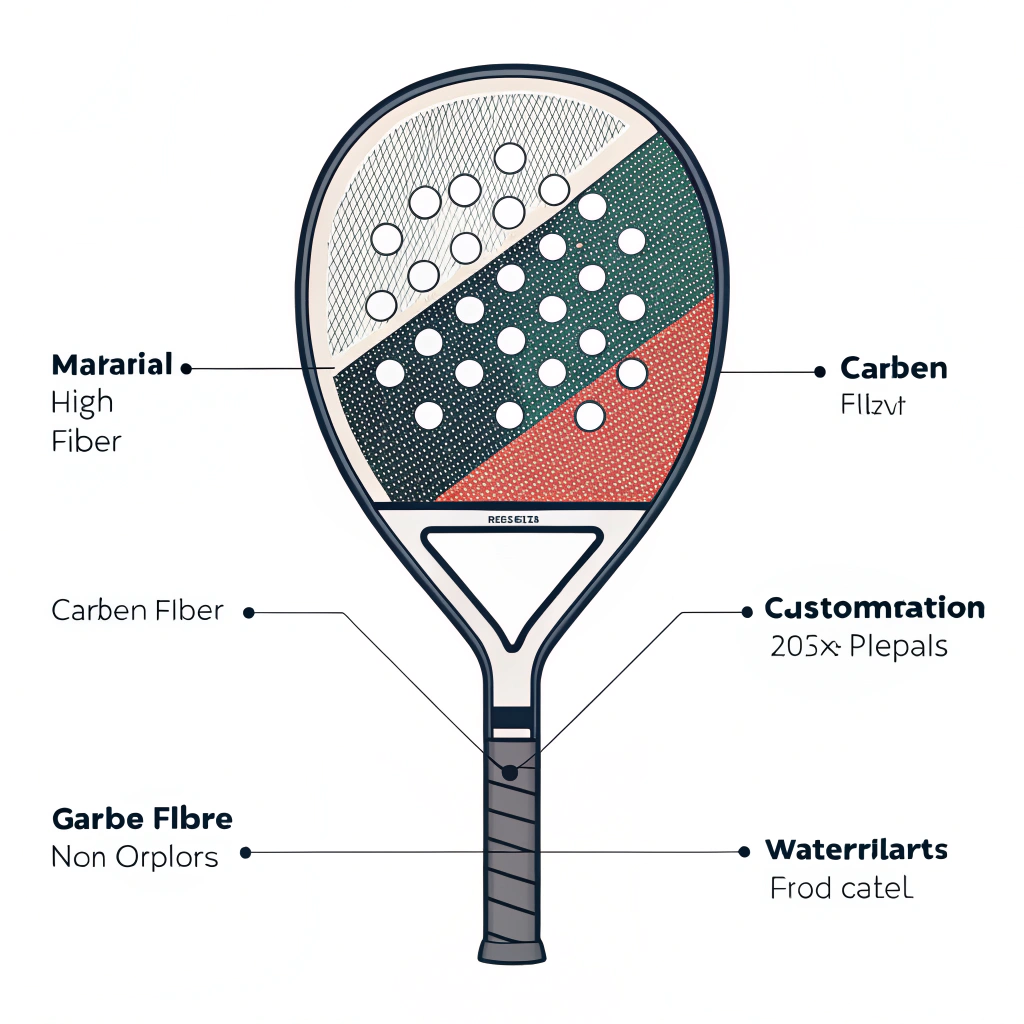

At NEX Padel, our expertise transcends shape design to include advanced selection of materials and robust customization options. When choosing a shape, the material compatibility is critical:

- Material Options: Our rackets are produced using high-quality glass fiber alongside advanced carbon fiber variants—3k, 12k, and 18k. Each material offers different properties, such as flexibility, impact resistance, and durability. For example, while 3k carbon fiber provides an excellent balance between strength and weight, 18k carbon fiber is ideal for high-performance applications where maximum rigidity is desired.

- Customization Options: In addition to selecting the shape and material, padel rackets can be further personalized through custom printing and color schemes, as well as tailored hand grip and handle cover designs that can incorporate your company logo. This degree of customization is particularly valuable for brands that want to differentiate themselves in a competitive market.

When considering customization and production timelines, detailed technical specifications, and available manufacturing techniques become powerful decision-making tools. Understanding the interplay between shape design and materials ensures that the end product not only meets but exceeds performance expectations.

Efficient manufacturing is central to achieving high performance and consistent quality. Here are some specific points that are particularly relevant to padel racket production:

- Advanced Molding Techniques: With shapes like teardrop and diamond, precision dies and CNC3 (Computer Numerical Control) machines are often necessary to maintain consistent quality. Precision engineering is critical when working with advanced carbon fiber materials.

- Quality Assurance Processes4: Given the importance of durability in padel rackets, every unit undergoes rigorous quality checks. Parameters such as balance point, vibration dampening, and impact resistance must be consistently verified.

- Quick Prototyping and Scale Production: At NEX Padel, rapid prototyping5 allows us to quickly iterate on design changes. This speed is advantageous not just for meeting demands, but also for adapting to new performance requirements emerging from market feedback.

- Collaborative Manufacturing: We proudly serve industry giants like Hirostar, Reebok, and Starvie. Such collaborations demand adherence to strict technical and quality standards, ensuring that each batch of rackets is production-ready for global sports markets.

Understanding these manufacturing facets adds a layer of confidence when choosing your next production partner. The combination of shape design, material choice, and advanced fabrication technology inches you closer to a product that will resonate with both professional players and recreational enthusiasts.

To summarize, choosing the appropriate padel racket shape depends on your specific target market and performance requirements:

- Round Shape: Ideal for brands catering to beginners and intermediate players who value control and consistency. It is also an economical choice with simpler manufacturing processes.

- Teardrop Shape: Offers a versatile solution for all-around players. This shape is a strong recommendation if your product strategy targets a broad audience that demands a balance of power and control.

- Diamond Shape: Best suited for aggressive, advanced players. It fits brands that want to focus on high-performance, offensive play, even if it means facing higher production costs and complex manufacturing challenges.

For procurement managers evaluating potential manufacturing partners, it’s essential to balance the technical performance characteristics with overall production feasibility. We suggest initiating small-scale runs for each shape, closely monitoring player feedback, and using these insights to iterate on design enhancements.

Given the complexity of technical specifications, investing in pilot studies and quality assurance metrics may yield better insights that can steer long-term procurement decisions. By establishing clear criteria regarding performance, customization potential, and manufacturing efficiency, the path to selecting the right racket shape becomes more straightforward and data-driven.

In conclusion, the decision between round, teardrop, and diamond padel racket shapes involves detailed analysis of performance priorities, manufacturing capabilities, and market positioning. For procurement managers and product developers, the key is to match the racket’s technical characteristics with consumer preferences and production strategies.

We recommend:

• Conducting targeted pilot studies to gather end-user performance data.

• Evaluating cost versus performance trade-offs using detailed comparative tables.

• Partnering with manufacturers like NEX Padel who bring advanced techniques, extensive material options, and robust customization capabilities to the table.

By synthesizing design, material, and manufacturing insights, you can confidently drive your product development strategy and secure a competitive advantage in today’s dynamic sports equipment market.

People Also Ask

-

How do padel racket shapes affect performance?

Each racket shape influences the distribution of weight and the location of the sweet spot, thereby affecting control, power, and maneuverability. Round shapes typically enhance control, teardrop shapes balance both control and power, while diamond shapes maximize power. -

What are the customization options for padel rackets?

Customization options include choices of material (such as different carbon fiber grades), custom shapes, color schemes, printing of logos on the frame or hand grip, and tailored handle covers. These allow brands to align the product with their unique identity and performance specifications. -

Which material options are best for padel rackets?

Material choices such as glass fiber and various grades of carbon fiber (3k, 12k, 18k) offer different balances of durability, weight, and performance. The optimal choice depends on desired racket characteristics, with high-performance applications typically favoring advanced carbon fiber variants.

-

carbon fiber variants: Click to learn about the different types of carbon fibers used in manufacturing, their properties, and how they impact the performance and durability of sports equipment. ↩ ↩

-

customization options: Click to explore how bespoke customization can help brands differentiate their products, optimize performance, and align with market demands. ↩ ↩

-

CNC: Click to understand Computer Numerical Control (CNC) technology, its role in precise manufacturing, and its impact on production efficiency in advanced industries. ↩ ↩ ↩2

-

Quality Assurance Processes: Click to read about quality assurance methodologies, standard protocols, and how rigorous QA processes drive consistent product performance and safety. ↩ ↩

-

rapid prototyping: Click to learn how rapid prototyping accelerates product development, enabling businesses to iterate designs quickly and reduce time-to-market. ↩ ↩