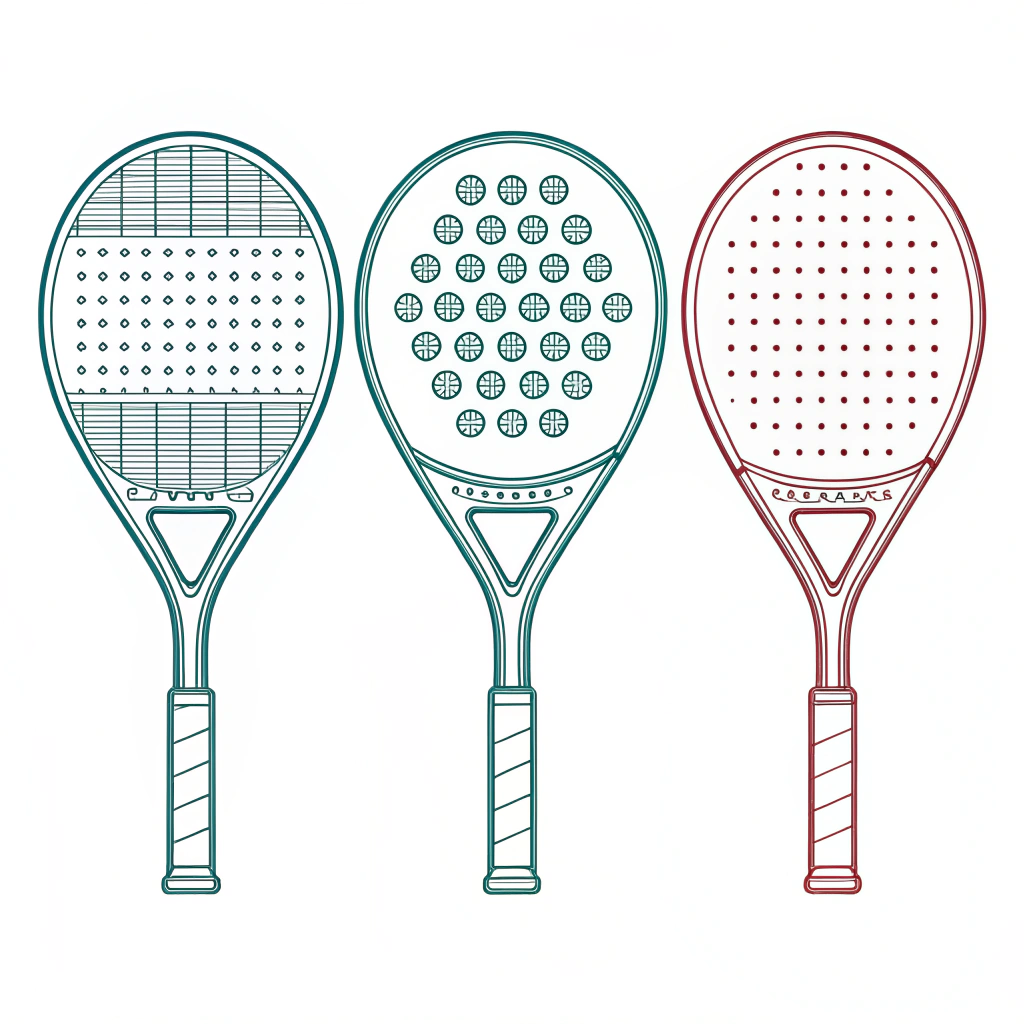

Padel rackets with a classic design continue to offer a balanced mix of proven performance and reliability, making them a solid choice for buyers evaluating long-term partnerships and quality consistency in the highly competitive B2B sporting goods market.

In today’s rapidly evolving padel market, procurement managers and sports equipment distributors face a critical decision: choosing between the timeless appeal of a classic padel racket design and the innovative features of modern alternatives. With changing consumer trends and advanced manufacturing techniques advanced manufacturing techniques1, understanding the core differences—and the specific benefits of each option—is key. This article provides a detailed comparison, focusing on high-performance manufacturing, material selection, customization capabilities, and supplier reliability.

The classic design of a padel racket has long stood for balanced performance, durability, and ease of use. In contrast, modern alternatives are evolving to deliver specialized performance enhancements by leveraging advanced materials and innovative shapes such as Diamond, Round, and Teardrop. Our company, NEX Padel, capitalizes on advanced manufacturing techniques to offer high-performance products built from materials like fiberglass and different grades of carbon fiber2 (3k, 12k, 18k). These materials cater to various performance needs from durability to a softer game-feel.

The materials used in padel racket production play a vital role in performance, weight distribution, and overall durability. Manufacturers need to offer options that meet both traditional and high-tech expectations. Here’s a closer look at the primary materials used:

- Fiberglass: Known for its flexibility and lower cost, fiberglass is a prevalent material in classic designs. It delivers good control and comfort, making it ideal for players who value consistency.

- Carbon Fiber: Offered in 3k, 12k, and 18k variants, carbon fiber is used to enhance stiffness, weight reduction, and overall performance.

- 3K Carbon: Typically delivers a stable yet somewhat rigid feel.

- 12K Carbon: Provides added flexibility for a softer hit, enhancing ball control.

- 18K Carbon: Combines durability with an optimal balance between toughness and elasticity.

These materials offer a spectrum of performance characteristics, enabling procurement managers to match product specifications with market demands.

| Material | Characteristics | Ideal For |

|---|---|---|

| Fiberglass | Lightweight, flexible, cost-effective | Balanced control and ease |

| 3K Carbon Fiber | Stable, rigid feel | Power delivery and durability |

| 12K Carbon Fiber | Increased flexibility, softer feel | Enhanced ball release |

| 18K Carbon Fiber | High durability, balanced performance | High-performance and longevity |

Different racket shapes cater to various playing styles and preferences. Below we compare the classic design with modern alterations in shape:

- Shape: Often follows a traditional outline emphasizing symmetry.

- Performance: Offers a balance between control and power.

- Customization: We support complete customization, including bespoke shapes and personalized designs like logo printing on the hand grip and handle flap.

- Market Position: Favored by buyers who prioritize proven performance and reliability.

- Shape: Tapers towards the top, enhancing power and precision in offensive play.

- Performance: Designed for aggressive shots; provides added force during spikes.

- Best For: Players looking to maximize shot strength, although it may sacrifice a bit of control for added power.

- Shape: Features a softer, more rounded profile offering increased maneuverability.

- Performance: Allows for excellent control and comfort, making it ideal for players emphasizing ball control.

- Best For: Those who require a blend of precision and comfort with a classic twist.

- Shape: Combines the benefits of both round and diamond shapes.

- Performance: Delivers balanced performance with a moderate power boost while maintaining high control.

- Best For: Versatile players who require a multipurpose racket for both offense and defense.

As a leading manufacturer, NEX Padel emphasizes production efficiency and high customization capabilities. Our advanced manufacturing techniques allow us to support both classic and innovative designs, ensuring that each product meets rigorous quality standards. The key production aspects include:

- Rapid Prototyping3: With our efficient sampling process, we can quickly translate design requirements into prototypes. This is critical for B2B buyers who need to test and validate products before mass deployment.

-

- Customization Capabilities4: Whether it's the racket shape—be it Diamond, Round, or Teardrop—or detailed elements such as hand grip logos, custom printed patterns, or personalized color schemes, our production team ensures that every specification is met.

- Quality Assurance: Every padel racket is subject to strict quality control procedures. From carbon fiber layering to final cosmetic details, we ensure that performance is not compromised.

- Supplier Reliability5: For long-term B2B partnerships, supplier reliability is crucial. Our proven track record with top brands like Hirostar, Reebok, and Starvie underlines our commitment to high standards and timely production.

Additionally, our padel balls, available in both 45% wool and 57% wool with Pressurized tube packaging, complement the racket offerings. This integrated approach demonstrates our capacity to deliver a complete sporting goods package to our partners.

Below is a more detailed comparison focusing on key factors that affect procurement decisions:

| Factor | Classic Design | Modern Alternatives |

|---|---|---|

| Performance Balance | High, with proven track record | Varies; specialized shapes for targeted performance (power, control, versatility) |

| Material Options | Fiberglass, basic carbon fiber | Advanced carbon fiber variants for enhanced performance (e.g., 12K, 18K) |

| Customization Capability | High; traditional yet flexible | High; supports innovative shapes and detailed personalized options |

| Production Lead Time | Optimized with proven methods | Similar efficiency; may require additional customization time |

| Market Adoption | Widely accepted among traditional players | Gaining popularity among performance-oriented players |

| Supplier Reliability | Consistent quality and historical reliability | Emerging trends with robust quality control processes |

This side-by-side comparison helps procurement managers decide whether the consistency and trust of a classic model align better with their market strategy than the innovative but varied performance profiles of modern alternatives.

Procurement professionals need to consider quality as a non-negotiable element. With our advanced production techniques, every padel racket undergoes thorough testing. This guarantees minimal defects and robust performance across all material grades. The classic design has been a benchmark for reliability, while modern designs bring innovative twists that may offer additional benefits under certain play styles.

Customization is a key differentiator in the B2B market. Some clients demand bespoke design elements that reflect their brand identity and meet specific performance criteria. For instance, customization extends to not only the racket’s shape but also the integration of personalized logos on the hand grip and handle cover. This flexibility allows distributors to cater to niche markets effectively.

In a world where supply chain efficiency directly influences market success, our ability to deliver products on time remains an important factor. The classic design leverages a time-tested production line, ensuring prompt delivery and consistency. Meanwhile, modern alternatives that incorporate more detailed customization steps still benefit from our streamlined production processes, ensuring that extended options do not delay deliveries.

Long-term value is closely tied to cost efficiency. Though modern alternatives potentially come with a higher production cost due to the precise engineering and enhanced material use, their benefits can justify the investment when targeting high-performance segments. Conversely, a classic design offers robust performance at a potentially lower overall cost, balancing the need for high quality with budget considerations.

Over the years, our partnership with industry leaders such as Hirostar, Reebok, and Starvie has demonstrated the practical benefits of choosing reliable, high-performance padel rackets. One client, focused on introducing a new line of padel products, opted for a classic design model due to its tested quality and dependable production timelines. Here are the key outcomes from the collaboration:

- Consistent Quality: The classic design deliveries matched stringent quality standards, ensuring minimal product returns and high customer satisfaction.

- Customization Excellence: Out-of-the-box customization options allowed the client to add unique features that enhanced brand identity across their product line.

- Faster Market Entry: Our rapid prototyping and sample testing enabled the client to validate product features quickly, leading to a successful market launch.

- Understanding Consumer Demand: By balancing traditional performance with subtle innovations, we managed to sell well to both novice and experienced padel players.

This case clearly illustrates that a classic padel racket design, when executed using advanced manufacturing techniques, can maintain a competitive edge even in a market offering many modern alternatives.

For procurement managers evaluating these options, the following steps could streamline the decision-making process:

-

Assess Market Demands: Look into the specific needs of your customer base. A well-established market might favor the classic design for its reliability, while niche segments could benefit from the specialized performance of modern alternatives.

-

Evaluate Customization Needs: Supplier flexibility in terms of customization can provide a significant competitive edge. Ensure that your potential supplier offers not only standard product configurations but also tailored solutions suited for long-term brand differentiation.

-

Analyze Total Cost of Ownership (TCO): While upfront costs may differ, consider the overall value proposition. Factoring in production efficiency, quality assurance, and timely delivery will help determine which option offers a better return on investment (ROI).

-

Pilot Testing: Before committing to a large order, consider ordering a pilot batch. This will allow you to test product performance in actual market conditions, ensuring that both the classic and modern designs satisfy your quality and performance criteria.

-

Establish Long-Term Partnerships: A supplier with consistent performance records and the capacity for iterative improvements is invaluable. Our ongoing collaborations with reputed brands underscore the reliability and continuous innovation in our offerings.

Choosing between a classic padel racket design and modern alternatives depends largely on your company’s specific market strategy, customer demographics, and operational priorities. The classic design provides time-tested reliability, balanced performance, and proven production efficiency. In contrast, the modern alternatives—be it the Diamond, Round, or Teardrop shapes—bring subtle innovations that can cater to premium segments and performance-oriented players.

For buyers who value consistent quality and a reliable supply chain, the classic design remains a powerful option. However, if your market demands cutting-edge features alongside customization, integrating modern alternatives into your product portfolio might be the key to tapping into emerging trends and higher-margin segments.

Ultimately, a careful evaluation of performance benefits, cost implications, and partnership opportunities can help you build a more resilient and competitive product lineup. We at NEX Padel stand ready to support your decision with our advanced manufacturing processes, comprehensive customization options, and unwavering commitment to quality.

Q: What is the USA version of padel?

A: Pickleball, which was created in 1965, is especially popular in the United States and Canada. In contrast, padel was developed in Mexico in the late 1960s and is particularly popular in Spain and other Spanish-speaking nations.

Q: Which is better, 3K or 12K carbon?

A: The key difference lies in flexibility—12K carbon is more flexible than 3K carbon, offering a softer feel on the court. This results in a different ball release dynamic, which might be preferable depending on the playing style required.

Q: Are expensive padel rackets worth it?

A: While padel relies on quality gear, the most expensive racket may not necessarily enhance your performance. Over time, as your equipment wears and your game evolves, investing in new equipment that meets your game’s needs is often more beneficial.

-

Advanced Manufacturing Techniques: Reading this article will provide insights into how modern production methods enhance efficiency, reduce production time, and improve overall product quality. ↩

-

Carbon Fiber: Learn about the properties and applications of various carbon fiber grades and how they contribute to the performance and durability of sporting equipment. ↩

-

Rapid Prototyping: Discover how quick iteration in the design process accelerates innovation, reduces time-to-market, and improves product development outcomes. ↩

-

Customization Capabilities: Explore the benefits of tailored product solutions that not only meet specific market needs but also help enhance brand differentiation and customer satisfaction. ↩

-

Supplier Reliability: Understand the critical role of consistent quality metrics and robust supply chain practices in establishing long-term, dependable B2B partnerships. ↩