Customized padel racket manufacturing delivers a competitive edge—by leveraging advanced production techniques1 and premium materials, businesses can create high-performance, visually distinct products that satisfy both player needs and B2B procurement criteria.

In today’s rapidly evolving sports equipment market, product managers and sourcing specialists are compelled to look beyond off-the-shelf padel rackets. Companies need solutions that combine superior quality with advanced customization options2. The challenge is to produce rackets that not only perform impeccably on the court but also enhance brand identity through tailored design elements. In this article, we delve into the problems associated with standard manufacturing, identify the causes behind the need for customization, and present a clear, structured approach to meet these challenges effectively.

Many companies in the padel market face a significant bottleneck when it comes to differentiating their product line. Traditional padel rackets often use one-size-fits-all designs and standard materials that may not fully exploit the advancements in carbon fiber materials3 and customization technology. With increasing competition from both established brands and new entrants, businesses must innovate to stay ahead.

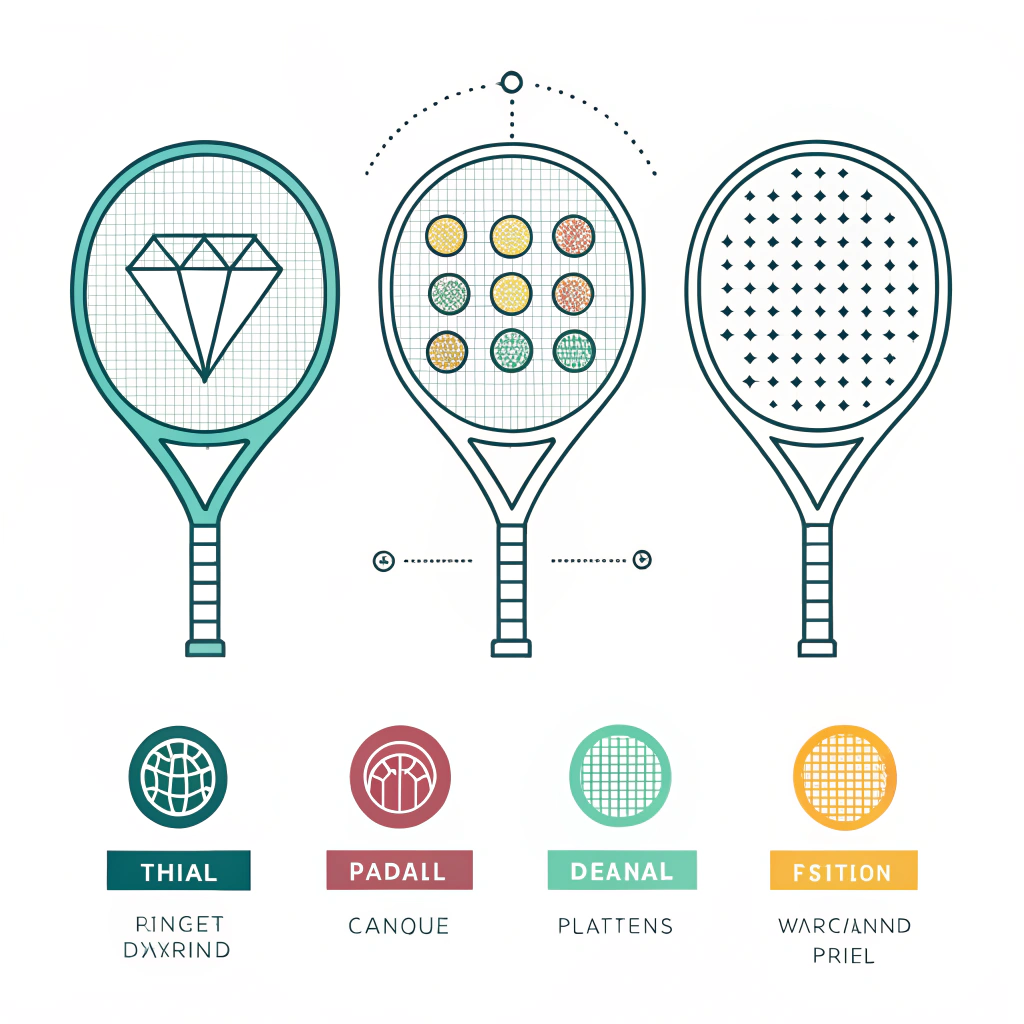

B2B buyers are not only looking for products that deliver high performance but also require a level of personalization that reflects their brand values. The inability to customize features—such as racket shapes (Diamond, Round, and Teardrop), logo placements, and color schemes—can limit market potential and reduce the opportunity for differentiation in a saturated market.

There are several critical reasons why off-the-shelf padel rackets are no longer sufficient for today’s dynamic market:

- Material Limitations: Standard manufacturing processes typically focus on one or two material choices. However, advanced padel rackets benefit significantly from a range of materials—from glass fiber to varying grades of carbon fiber (3K, 12K, and 18K). Each material offers different performance characteristics and cost implications.

- Customization Demand: With consumer trends leaning towards personalized sports equipment, a customizable padel racket can significantly boost brand recognition. Options like custom logo printing, unique coloration, and tailored grip styles are increasingly in demand.

- Production Speed and Precision: In a global market, timely production is crucial. The balance between rapid prototyping and maintaining precision manufacturing standards is essential, particularly when sourcing for high-performance equipment.

- Quality Assurance: The rigorous quality control required to ensure that high-performance padel rackets meet international standards is a common challenge. From material consistency to the final product’s durability, manufacturers must oversee every detail.

To overcome these challenges, advanced manufacturing techniques provide a pathway to innovation while ensuring high quality. Here are the key components of an effective solution:

Using a variety of materials is critical in meeting different player preferences and performance needs. Manufacturers now incorporate:

- Glass Fiber: Offers a balanced approach for durability and cost-effectiveness.

- Carbon Fiber (3K, 12K, 18K): Provides increased strength and stiffness. The differences in fiber counts result in variable flexibility and vibrational dampening properties.

Below is a table summarizing the key differences among common materials:

| Material Type | Strength | Flexibility | Weight | Application |

|---|---|---|---|---|

| Glass Fiber | Moderate | High | Medium | Entry-level and mid-range rackets |

| Carbon 3K Fiber | High | Moderate | Light | Standard high-performance |

| Carbon 12K Fiber | Very High | Low | Ultra-light | Elite, competition-focused |

| Carbon 18K Fiber | Extreme | Minimal | Ultra-light | Custom, professional-level |

This breakdown helps businesses decide on the optimal material based on performance requirements and budget considerations.

One of the standout benefits of partnering with a specialized manufacturer is the ability to offer extensive customization:

- Racket Shapes: Options like Diamond, Round, and Teardrop allow players to choose a racket that suits their style and performance advantages. Full customization of shapes is available to match specific market needs.

- Custom Graphics & Logo Printing: Branded elements, including color choices and intricate designs, can be customized to reflect the unique identity of each partner brand. This not only promotes brand recognition but also builds customer loyalty.

- Accessory Customization: Beyond rackets, customization extends to hand grips and hand towel covers. Custom logos and designs help maintain brand consistency across the product line.

- Padel Balls: Our customization process doesn’t stop at rackets. Padel balls, manufactured under stringent quality control, come with two options—45% wool and 57% wool—and are packaged using a pressurized tube to ensure consistent pressure retention.

3. Precision Manufacturing and Rapid Prototyping4

To cater to the time-sensitive requirements of B2B clients, our manufacturing process emphasizes rapid prototyping without sacrificing quality. This involves:

- Advanced Molding Techniques: Using state-of-the-art molds and precision calibration ensures every racket meets strict quality benchmarks.

- Iterative Sample Testing: We offer quick sample runs that allow clients to assess the product's performance and aesthetics before mass production begins.

- Streamlined Workflow: Customized orders are processed rapidly, reducing turnaround times for special editions or limited-run batches.

The integration of these practices not only assures quality but also minimizes the risk of production delays, which is essential for maintaining customer trust in competitive B2B relationships.

Quality assurance is a cornerstone of our manufacturing process. Rigorous testing phases are implemented at each step—starting from raw material selection to the final product assembly. Key aspects include:

- Consistent Material Testing: Ensuring that each batch of carbon fiber or glass fiber adheres to strict performance standards.

- Performance Testing: Rackets are subjected to stress tests that simulate on-court conditions, ensuring durability and performance consistency.

- Certification Compliance: We maintain relevant industry certifications that vouch for our manufacturing standards, reassuring B2B buyers of the product’s reliability.

Integrating these quality control measures significantly reduces the risk of defects and adds reassurance for companies that need to meet global standards.

While customized manufacturing offers many advantages, there are several considerations to keep in mind:

- Cost Implications: Custom projects may incur higher initial costs due to unique tooling, mold creation, and premium material selection. It is important for B2B partners to weigh these costs against the long-term benefits of differentiated product offerings.

- Minimum Order Quantities (MOQs)5: Customization might require larger order volumes. Businesses must plan their inventory and marketing strategies accordingly to maximize economies of scale.

- Production Complexity: The more customized a product, the more complex the production process becomes. This could potentially impact lead times if not managed carefully.

- Market Adaptation: While customization can drive sales through differentiation, it is crucial for companies to understand their target market’s requirements thoroughly to avoid over-engineering products that may not garner sufficient demand.

Our experience working with leading brands such as Hirostar, Reebok, and Starvie has provided insightful data on the benefits of customization. For instance:

- A case where a partner opted for a fully customized teardrop designed racket showed a 20% increase in market traction within the first quarter post-launch.

- Utilization of carbon 12K fiber in elite-level rackets resulted in a 15% improvement in endurance and player satisfaction, as demonstrated by performance testing and user feedback.

- Customized accessory integration, such as branded hand grips and coordinated padel balls, contributed to a more cohesive brand experience, enhancing customer loyalty and opening up cross-promotional opportunities.

Data like this reinforces that while the initial investment in customization may be higher, the returns in terms of market differentiation and customer engagement can be substantial.

Custom padel racket manufacturing offers significant advantages by blending high-performance materials, advanced customization techniques, and strict quality control to produce equipment that stands out in a competitive market. For businesses operating in the sports equipment sector, particularly within padel, the following actionable recommendations can act as a guideline for successful procurement and product differentiation:

- Assess Material Requirements: Begin by evaluating the material—whether glass fiber or the different grades of carbon fiber—to ensure that the racket meets performance as well as cost expectations.

- Define Customization Goals: Identify which aspects of the racket (shape, graphics, accessories) can best enhance your brand profile and customer value.

- Utilize Rapid Prototyping4: Engage manufacturers who offer rapid prototyping to ensure that the final product aligns with your specifications before committing to full-scale production.

- Implement Rigorous Quality Checks: Prioritize factories with robust quality control measures and relevant certifications to safeguard product performance.

- Plan for Long-Term Differentiation: Recognize that customization is not only a short-term marketing tool but also a long-term strategy for bolstering customer loyalty and market share.

By partnering with a manufacturer like NEX Padel, which excels in precision manufacturing and adheres to advanced production techniques, companies can confidently navigate the challenges of today’s competitive market and achieve differentiated product offerings that resonate with their target audience.

People Also Ask

-

What are the key factors in padel racket customization?

Answer: The key factors include the selection of advanced materials such as glass fiber and various grades of carbon fiber, the ability to customize shapes (Diamond, Round, Teardrop), custom graphics and accessory options, rapid prototyping capabilities, and comprehensive quality control measures. -

How do advanced manufacturing techniques benefit padel racket performance?

Answer: Advanced manufacturing techniques ensure precision in production, maintain consistent material properties, allow for rapid prototyping and on-demand customization, and enhance overall product performance by using state-of-the-art molding and quality assurance processes. -

How can padel rackets be tailored for different player needs?

Answer: Padel rackets can be tailored through customizable shapes, selection of material types (e.g., differing grades of carbon fiber), personalized color and logo designs, and optional accessory customization such as branded hand grips and complementary padel balls, ensuring that each racket meets specific performance and aesthetic requirements.

-

advanced production techniques: Click the footnote to understand cutting-edge production methods that improve efficiency and product quality, crucial for staying competitive in the market. back ↩

-

advanced customization options: Click the footnote to learn how leveraging advanced customization options can help tailor products to meet specific customer and brand requirements, driving market differentiation. back ↩

-

carbon fiber materials: Click the footnote to explore an in-depth look at the properties, benefits, and applications of carbon fiber in enhancing the performance and durability of sporting goods. back ↩

-

Rapid Prototyping: Click the footnote to discover how rapid prototyping accelerates product development cycles, ensuring that designs meet both performance and aesthetic standards before mass production. back ↩ ↩2

-

Minimum Order Quantities (MOQs): Click the footnote to gain insights into managing MOQs effectively, balancing production costs with inventory needs in a B2B procurement context. back ↩