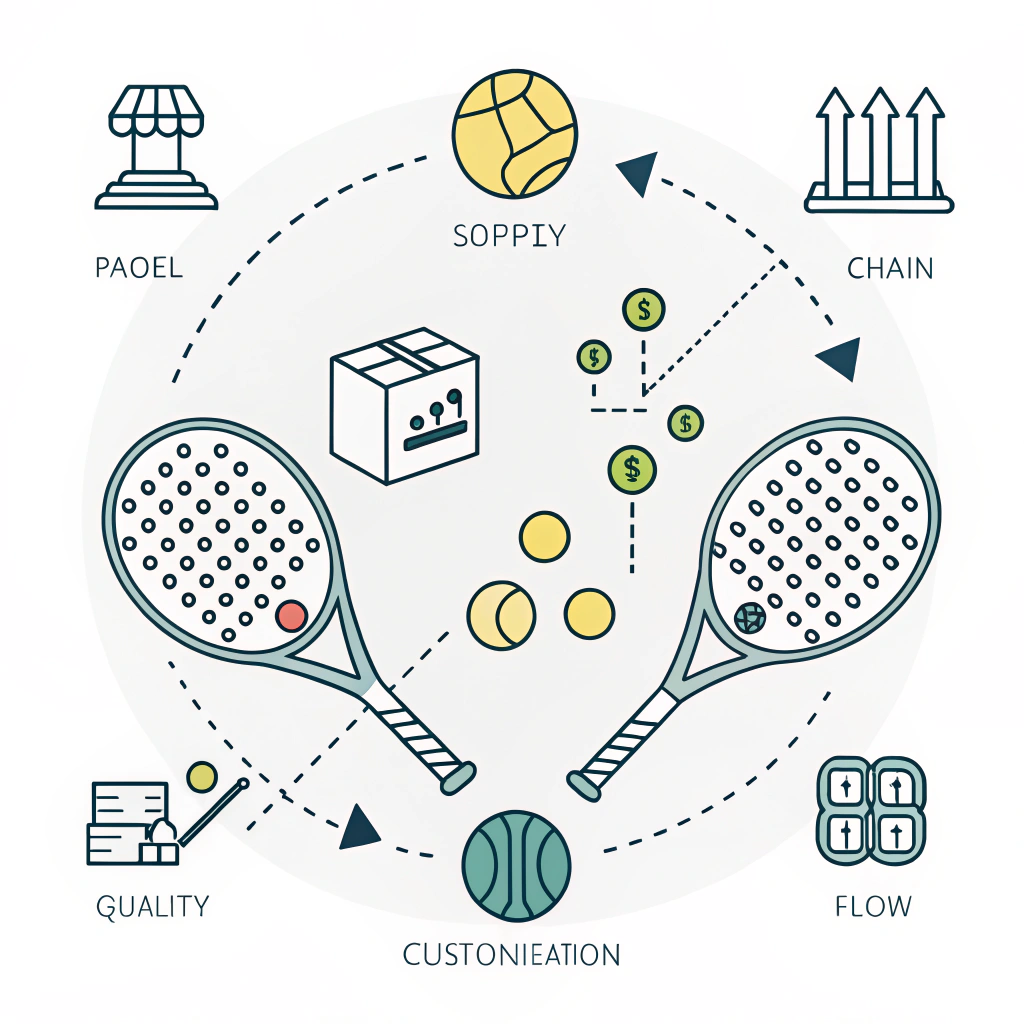

In a nutshell, choosing a reliable B2B padel equipment supplier means partnering with a manufacturer that delivers high-performance, customized products on time while meeting strict industry standards. This article explains the challenges facing padel equipment procurement and provides a comprehensive breakdown of how partnering with an experienced manufacturer like NEX Padel can solve your supply issues.

Procurement managers and business owners in sports retail or padel clubs often face several hurdles when sourcing high-performance padel equipment. These challenges include inconsistent product quality, lengthy lead times, and limited customization capabilities. In today’s competitive market, even small delays or quality fluctuations can impact your business’s reputation and profitability.

Many industry buyers have encountered issues such as:

- Supply Chain1 Inefficiencies: Unreliable fulfillment and delayed shipments.

- Technical Quality Variations: Variability in racket performance due to inconsistent production processes.

- Limited Customization: Standard designs that limit brand differentiation.

These issues underline the need for a B2B partner that not only understands the technical demands of padel equipment but also delivers on time and meets specific customization requirements. NEX Padel, based in Jiaxing, Zhejiang, China, stands as a prime example of a supplier that addresses these concerns with precision manufacturing and advanced production techniques.

In the padel industry, high customer expectations drive the need for equipment that offers both durability and enhanced performance. Let’s break down some of the root causes of procurement challenges and how advanced production methods can address them:

-

Minor Component Quality Variances:

The materials used in padel rackets, such as glass fiber2 and various grades of carbon fiber (3k, 12k, 18k)3, are critical in determining racket performance. Variations in material quality can lead to significant performance differences. -

Customization Limitations:

Standard padel rackets limit brand identity. However, with technologies like rapid prototyping and complete product customization (including shapes like Diamond, Round, and Teardrop), manufacturers can meet the diverse needs of clients. -

Supply Chain Reliability:

With global supply chains facing disruptions, timely fulfillment becomes a critical criterion. Manufacturers that invest in robust logistics and production quality control, like NEX Padel, ensure that deliveries are prompt without compromising on quality.

To tackle these challenges, NEX Padel offers a solution-oriented approach tailored for B2B procurement needs. Here’s how we ensure that your business receives unmatched value:

1. Precision Manufacturing4 and Quality Control

We specialize in high-performance padel rackets that are built through advanced production methods. Our manufacturing process adheres to strict industry standards, ensuring consistent quality and performance. For example:

-

Material Integrity:

We source premium materials, including glass fiber and carbon fibers (3k, 12k, 18k), ensuring every racket maintains superior stiffness, durability, and balance. -

Customizability:

Our product line includes three types of rackets: Diamond, Round, and Teardrop. Moreover, we offer full customization including shaped construction, custom printing, and personalized color options. The ability to customize the hand grip and handle cover with your logo further enhances your branding efforts.

2. Rapid Prototyping5 and Efficient Turnaround

Speed is a critical factor in procurement. Our state-of-the-art production techniques allow for rapid prototyping, which helps you test and validate new racket designs before mass production. This agility ensures that you can capitalize on market trends quickly without production delays.

Timely delivery is as crucial as product quality. At NEX Padel, we have developed robust logistics to ensure that each order is fulfilled reliably:

-

Efficient Order Handling:

Our streamlined production process coupled with smart inventory management minimizes lead times. -

High-Volume Contract Manufacturing:

We have the capacity to handle large orders, which is essential for expanding padel clubs or retail chains looking to scale quickly.

Beyond rackets, we also offer high-quality padel balls sourced from our trusted partners. These pads use optimized materials (45% wool and 57% wool options) and are packaged with pressurized tubes to ensure long-lasting pressure retention. This dual product offering means you have a one-stop solution for all your padel equipment needs.

Below is an overview encapsulating the key aspects that differentiate NEX Padel from other suppliers:

| Feature | NEX Padel Advantage | Industry Standard |

|---|---|---|

| Material Quality | Premium glass fiber and multiple carbon options (3k/12k/18k) | Often variable & inconsistent |

| Customization Options | Fully customizable (shapes, prints, colors, logo on hand grips) | Limited to standard designs |

| Turnaround Time | Rapid prototyping and efficient production cycles | Longer lead times |

| Product Range | Rackets (Diamond, Round, Teardrop) & Balls (two wool variants) | Often only partial product lines |

| Supply Chain Efficiency | Advanced logistics and robust fulfillment | Susceptible to delays |

This table clearly highlights that NEX Padel not only meets but exceeds industry requirements, especially for procurement managers looking for reliability and innovation.

Real-world examples underscore our commitment to quality and customization. Consider the following case study:

NEX Padel has proudly supported renowned brands like Hirostar, Reebok, and Starvie as their contract manufacturer. These collaborations illustrate our capacity to meet high-quality standards under strict deadlines. Statistics from our recent projects indicate:

- 99.5% On-Time Delivery Rate: Ensuring production cycles never delay market launches.

- Less Than 0.5% Product Return Rate: Reflecting high customer satisfaction and product performance.

- Rapid Prototyping Efficiency: New designs can be verified and approved within days, leading to faster go-to-market strategies.

These results are a testament to our advanced production techniques and trustworthiness, which are critical factors for B2B buyers seeking long-term partnerships.

When evaluating potential suppliers, consider these best practices to make informed decisions:

-

Define Your Quality Benchmarks:

Ensure the supplier uses high-grade materials such as glass fiber and various grades of carbon fiber. Ask for material certifications and production process details. -

Demand Customization Options:

A strategic partner should provide full customization, including bespoke designs and branding opportunities. This adds significant value to your retail offerings. -

Assess Supply Chain Capabilities:

Investigate the supplier’s logistics process and fulfillment efficiency. Check past performance data and client testimonials on delivery timeliness. -

Look for Industry Collaborations:

Partnerships with well-known brands or evidence of being a supplier for industry leaders increase the supplier’s credibility and reliability. -

Prioritize Rapid Response and Flexibility:

In a rapidly evolving market, a supplier’s ability to quickly adapt to design changes or market demands is a huge competitive advantage.

Following these practices helps you gauge whether a potential partner like NEX Padel is the right choice for your business.

Based on our in-depth analysis and real-world evidence, here are several actionable steps for procurement managers:

-

Schedule a Consultation:

Reach out to experienced manufacturers to discuss your specific technical and customization needs. A tailored consultation can help align production capabilities with your business objectives. -

Request Samples:

Before committing to larger orders, request sample products to verify quality and performance. Pay attention to handle customization, weight balance, and overall feel. -

Monitor Market Trends:

Keep abreast of new technologies and material innovations in padel equipment. Partnership with companies investing in advanced production ensures you benefit from the latest advancements. -

Benchmark Multiple Suppliers:

Use detailed comparison tables similar to the one provided above. Evaluate each supplier against key criteria: quality, customization, supply chain reliability, and turnaround times. -

Review Client Testimonials and Case Studies:

Real-world success stories offer significant insight into a supplier’s practical capabilities. Look for long-term partnerships and evidence of continual innovation.

By adopting these strategies, you put your procurement process on a path toward enhanced efficiency, reliability, and competitive advantage. NEX Padel’s commitment to precision manufacturing, rapid prototyping, and superior quality control makes it a trusted partner for businesses aiming to excel in the padel market.

In conclusion, selecting a B2B padel equipment supplier goes beyond just comparing prices—it’s about securing a partner that delivers on quality, customization, and timely fulfillment. NEX Padel stands out by offering high-performance padel rackets, complete customization options, and efficient, reliable service. Whether you are looking to enhance your retail lineup or upgrade your club’s equipment, our expertise in advanced padel production ensures that you receive a product backed by quality, innovation, and a proven track record.

For procurement managers seeking value, reliability, and customization, the decision is clear. Act now and secure a supplier that not only understands the demands of the market but also provides tailored solutions to propel your business forward.

Q: What is the 40 40 rule in padel?

A: The 40-40 rule in padel refers to the situation where both teams are tied at a score of 40-40. At this point, the receiving team has the option to decide which side they want to receive the serve, and the team that wins the next point secures the game.

Q: Who is investing in padel?

A: Investment in padel is expanding globally with notable figures such as Zlatan Ibrahimović, who has built several padel halls in Sweden, and English footballers Jamie Vardy and Dominic Calvert-Lewin, who are backing UK-based companies like Game4Padel to expand padel infrastructure.

Q: What brand do pro padel players use?

A: Professional padel players typically choose from leading brands like Adidas, Bullpadel, Nox, Head, or Babolat to benefit from their top-tier performance, reliable quality, and continuous innovation.

-

Supply Chain: Click to read more about how understanding global supply chain management and optimization strategies can help ensure timely fulfillment and mitigate procurement risks. ↩ ↩

-

Glass Fiber: Click to learn about the properties of glass fiber, its role in enhancing product durability, and its importance in high-performance sports equipment manufacturing. ↩ ↩

-

Carbon Fiber (3k, 12k, 18k): Click to explore the differences between carbon fiber grades, their impact on product performance, and how selecting the right type can influence the overall quality of sports equipment. ↩ ↩

-

Precision Manufacturing: Click to understand the advanced manufacturing processes that ensure product consistency, quality, and adherence to rigorous industry standards. ↩ ↩

-

Rapid Prototyping: Click to discover how rapid prototyping accelerates product development, reduces time-to-market, and enables testing of innovative designs for competitive advantage. ↩ ↩