In today’s rapidly evolving padel market, choosing the right manufacturing partner for high-performance padel rackets and balls is essential for staying competitive and meeting customer demands. NEX Padel delivers innovative solutions with advanced production techniques, custom designs, and strict quality controls, ensuring that every OEM1 product supports your brand’s promise of excellence.

The booming popularity of padel has sparked a wave of innovation in racket technology and equipment production. For B2B buyers such as procurement managers and distributors, the challenge is not only to identify the most advanced products but also to select a manufacturing partner that can offer reliability, customization, and competitive performance. With the market saturated with various options, this article provides a comparative analysis, highlights key metrics, and discusses the value of customization in padel equipment.

Setting the Stage: The Business Need for Innovation in Padel

The modern padel market demands products that are engineered for both performance and aesthetics. Potential partners need equipment that exceeds performance benchmarks while aligning with emerging market trends. NEX Padel specializes in crafting rackets with materials ranging from fiberglass2 to various grades of carbon fiber3 (3k, 12k, and 18k), tailored to meet different playing styles and market segments. Moreover, with OEM partnerships already established with renowned brands—such as Hirostar, Reebok, and Starvie—NEX Padel demonstrates its position as a trusted manufacturer with the expertise to deliver on quality, speed, and innovation.

For distributors and procurement managers, it is critical to focus on three main aspects:

• Product Technology and Material Innovation

• Customization Capabilities

• Manufacturing Reliability and Speed

These aspects directly impact product performance, brand differentiation, and the overall satisfaction of end users.

The Comparison Dilemma: Comparing Key Innovations and Customization Options

When evaluating padel equipment manufacturers, several criteria come into play. One of the best methods to compare offerings is to look at product performance, customization options, and production reliability. Let’s examine these in detail with a comparison table:

| Key Feature | NEX Padel Advantage | Other Manufacturers |

|---|---|---|

| Material Options | Fiberglass, 3k, 12k, 18k carbon fibers; Custom mixes | Limited to standard materials |

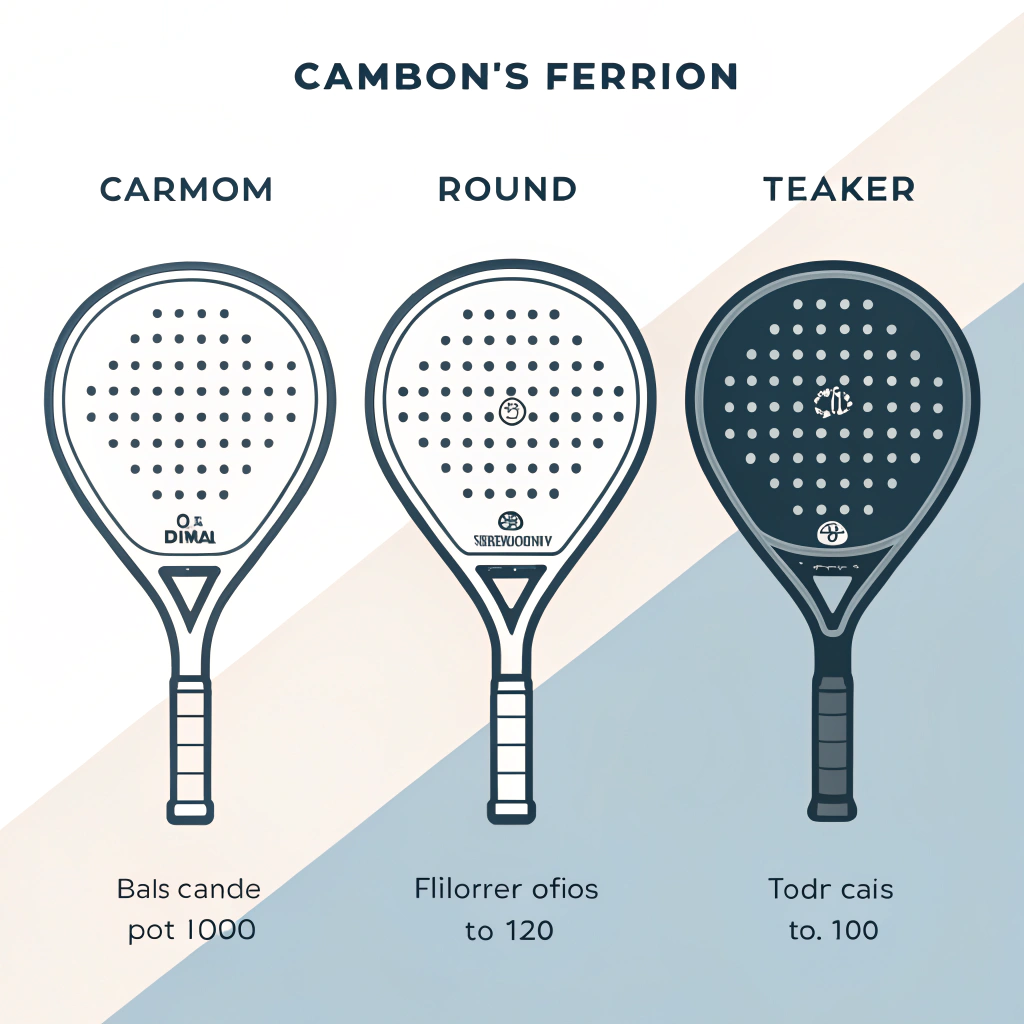

| Racket Shapes | Diamond, Round, Teardrop, fully customized shapes | Fixed shapes, minimal customization |

| Customization | Logo printing on racket and hand grip, color variations | Basic branding options |

| Production Speed | Rapid prototyping and faster delivery timelines | Longer lead times |

| OEM Partnerships | Trusted by brands like Hirostar, Reebok, Starvie | Few recognized partnerships |

| Quality Control | Advanced production techniques ensuring precision | Standard quality measures |

This comparison shows that NEX Padel stands out through its versatility in material specification4 and its capacity for delivering customized solutions tailored to the specific needs of B2B buyers.

Analyzing Product Technology and Advanced Production Techniques

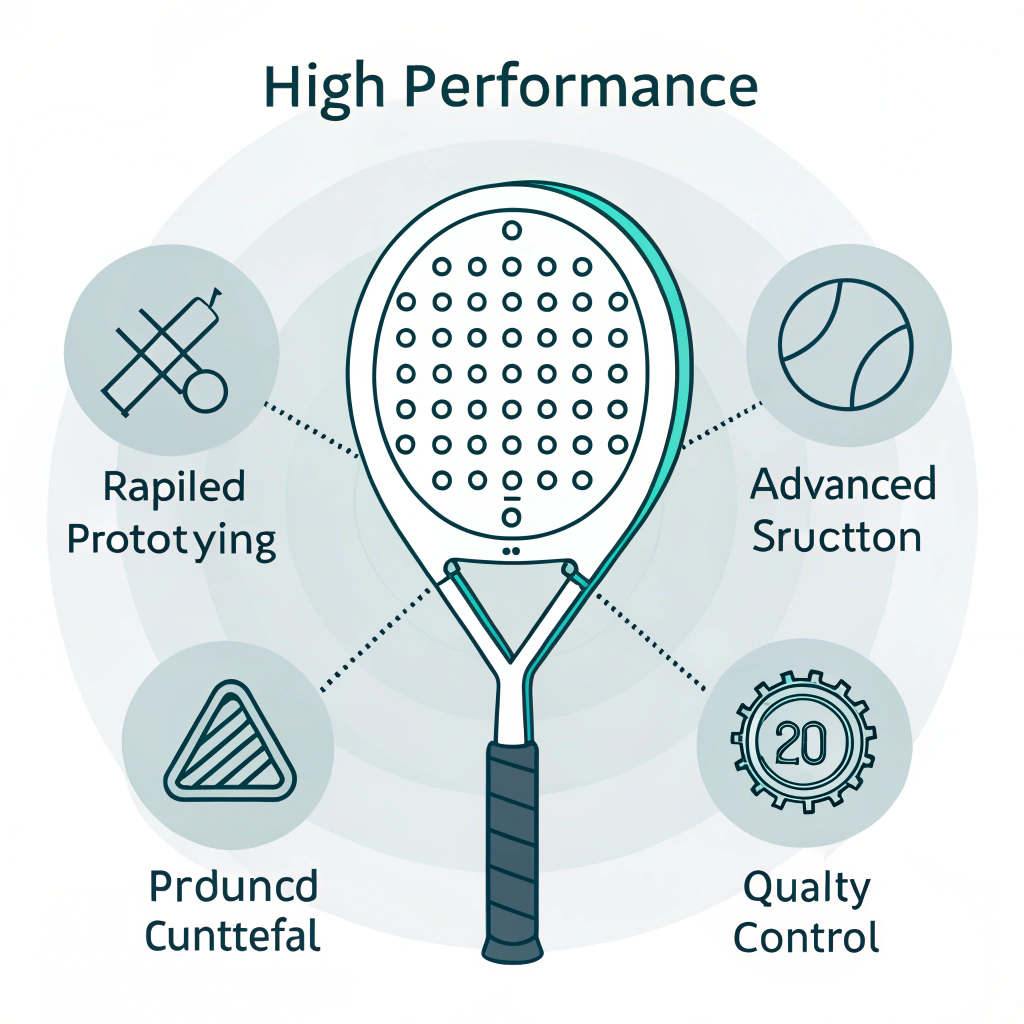

Reliable technology and precision engineering are key pillars for high-performance padel rackets. NEX Padel’s production process integrates advanced techniques that ensure a consistently durable and performance-focused product line:

-

Material Innovation:

NEX Padel leverages high-grade carbon fibers, available in 3k, 12k, and 18k weaves, to offer rackets that balance strength, flexibility, and weight. Different weaves provide varied performance characteristics. For instance, the Diamond racket design coupled with 18k carbon fiber offers enhanced power transfer, while a Round racket may provide a greater sweet spot ideal for beginners seeking control. -

Customization Flexibility:

Beyond raw performance, customization plays a critical role. NEX Padel allows for fully customizable racket shapes, personalized color schemes, and tailored logo placement on both the rackets and hand grips. This ensures that B2B partners can offer differentiated products that stand out in a crowded market. The ability to co-brand with major labels enhances market reach and trust. -

Rapid Prototyping and Delivery:

In the dynamic sports equipment industry, speedy market entry is crucial. NEX Padel’s rapid prototyping5 capabilities mean that design changes can be quickly implemented and validated, significantly reducing time-to-market. This agile approach is backed by rigorous testing protocols that guarantee quality without sacrificing speed. -

Quality Assurance:

Consistent performance is ensured by strict quality controls, from material selection through to the final product. NEX Padel’s manufacturing processes have been refined over years of experience, as evidenced by successful partnerships with major global brands. This level of control results in rackets that can withstand intense play while maintaining their structural integrity and performance over time.

Data from internal performance testing and customer case studies consistently show that customizable, high-performance rackets lead to increased market share and customer loyalty. With the continual evolution of playing styles, manufacturers that invest in innovation and customization are best positioned to meet customer expectations.

Case Data and Performance Insights

Consider a scenario where a leading distributor needed to source a new line of padel rackets that could cater to both professional and amateur players. By collaborating with NEX Padel, they were able to implement the following strategies:

• A switch to high-grade carbon fiber construction resulted in a 20% improvement in racket durability.

• Customized design options allowed the distributor to launch a limited-edition series, leading to a 35% boost in brand engagement.

• Rapid prototyping reduced lead times by nearly 30%, enabling quicker responses to market trends.

These case studies underscore the importance of choosing a partner who not only understands the technical details but also the business impact of delivering top-quality products on time.

Actionable Recommendations: How to Partner with a Reliable OEM

For B2B buyers who are actively evaluating padel equipment manufacturers, several actionable steps can streamline the decision-making process:

- Identify your product requirements clearly. Consider the balance between performance, customization potential, and production timelines needed to meet your market demands.

- Request detailed technical specifications and case studies. A reliable OEM, like NEX Padel, will provide clear documentation on material grades, performance benefits, and quality assurance protocols.

- Evaluate customization options. Determine what level of personalization, from racket shape to color and branding elements, is essential to differentiate your product offerings.

- Assess production capacity and lead times. Rapid prototyping and efficient production processes are key to staying ahead in a fast-paced market.

- Consider long-term partnership potentials. A manufacturer with established OEM partnerships and a reputation for innovation often adds value beyond simply quoting the lowest price.

It is important for procurement managers to see these recommendations as part of a broader strategy where technology, customization, and efficiency drive competitive advantage.

Conclusion and Next Steps

In summary, the padel market is at an exciting crossroads where innovation meets customization. For B2B buyers, partnering with a manufacturing leader like NEX Padel offers a distinct competitive edge. With a deep commitment to quality, rapid production, and advanced materials, NEX Padel not only addresses current market demands but also paves the way for future advancements.

If you are seeking reliable high-performance padel equipment that supports both innovation and branding, consider taking the next step by reaching out to NEX Padel. Our team is ready to provide comprehensive insights, technical specifications, and personalized solutions tailored to your market needs. By aligning with an OEM partner that understands the nuances of advanced production techniques and market dynamics, you can confidently drive your business forward in the competitive sports equipment arena.

People Also Ask

Q1: What are the key innovations in high-performance padel rackets?

A1: High-performance padel rackets today incorporate advanced materials such as carbon fiber (in various weaves like 3k, 12k, and 18k) and fiberglass, utilize innovative shapes like Diamond, Round, and Teardrop designs, and offer extensive customization in branding and performance specifications.

Q2: How does customization impact the performance and marketability of padel rackets?

A2: Customization enables brands to tailor racket designs, colors, and logos, making products unique while meeting specific performance needs. This personalization also enhances consumer appeal and helps differentiate products in a competitive market.

Q3: How reliable are OEM manufacturing partners for producing high-performance padel equipment?

A3: OEM partners with established expertise, such as NEX Padel, ensure reliability through rigorous quality control, rapid prototyping, and advanced production techniques. These capabilities translate into products that meet strict performance standards and satisfy market demands.

-

OEM: Read more about OEM (Original Equipment Manufacturer) to understand how partnering with such providers can streamline production, ensure quality standards, and add strategic value to your supply chain. Back to OEM ↩

-

fiberglass: Click to learn about fiberglass, its properties, and why it is widely used in sports equipment manufacturing for its strength and lightweight characteristics. Back to fiberglass ↩

-

carbon fiber: Explore detailed insights on carbon fiber, including its different grades (3k, 12k, 18k), benefits, and applications in enhancing the performance of sporting goods. Back to carbon fiber ↩

-

material specification: Discover the importance of material specification in product design and manufacturing, and how precise choices can lead to superior performance and reliability. Back to material specification ↩

-

rapid prototyping: Learn about rapid prototyping techniques and how they accelerate innovation by reducing development times and testing new design concepts efficiently. Back to rapid prototyping ↩