Factory visits to padel racket manufacturing facilities are essential for ensuring quality control1, building strong supplier relationships, and tailoring product customization, making them a worthwhile investment for brands and procurement managers alike.

In today’s competitive padel equipment market, first-hand inspection of manufacturing facilities can be a game-changer. Direct factory engagement not only deepens your understanding of production processes but also enables you to verify quality control1 measures, ensure material compliance, and assess the supplier’s ability to meet your customization2 needs. For procurement managers and brand owners, the decision to visit a factory is a strategic move that bridges the gap between abstract promises and operational realities.

Modern padel racket production involves advanced materials—from glass fiber to various grades of carbon fiber such as 3k3, 12k, and 18k. While technical specifications and production certifications provide valuable information, they rarely convey the full picture. Procurement managers often face challenges such as:

• Inconsistent quality control across production batches

• Limited transparency in supplier operations

• Communication barriers with remote production teams

• Risks related to production delays or material inconsistencies

These risks can be minimized through direct factory visits. By inspecting the facility firsthand, you can evaluate the production environment, audit supplier practices, and confirm that custom printing, hand grip logos, and other specialized features meet your precise requirements.

Several underlying factors contribute to the challenges in padel racket manufacturing:

- Material Variability: Manufacturers use a range of materials. Without a hands-on visit, it is difficult to verify if suppliers consistently use high-grade materials that meet your standards.

- Production Process Complexity: Modern production lines incorporate advanced techniques that require skilled labor and stringent quality controls. A remote evaluation might miss subtle process flaws that could impact product longevity.

- Supplier Overcommitment: Some suppliers might promise rapid turnaround times; however, without verifying on-site, you risk delays or inconsistent quality when the promised standards are not met.

- Limited Customization Oversight: Custom features such as personalized printing and logo applications demand meticulous oversight during production. Factory visits help ensure that these customizations are executed accurately.

Understanding these factors is critical to making an informed decision about on-site inspections.

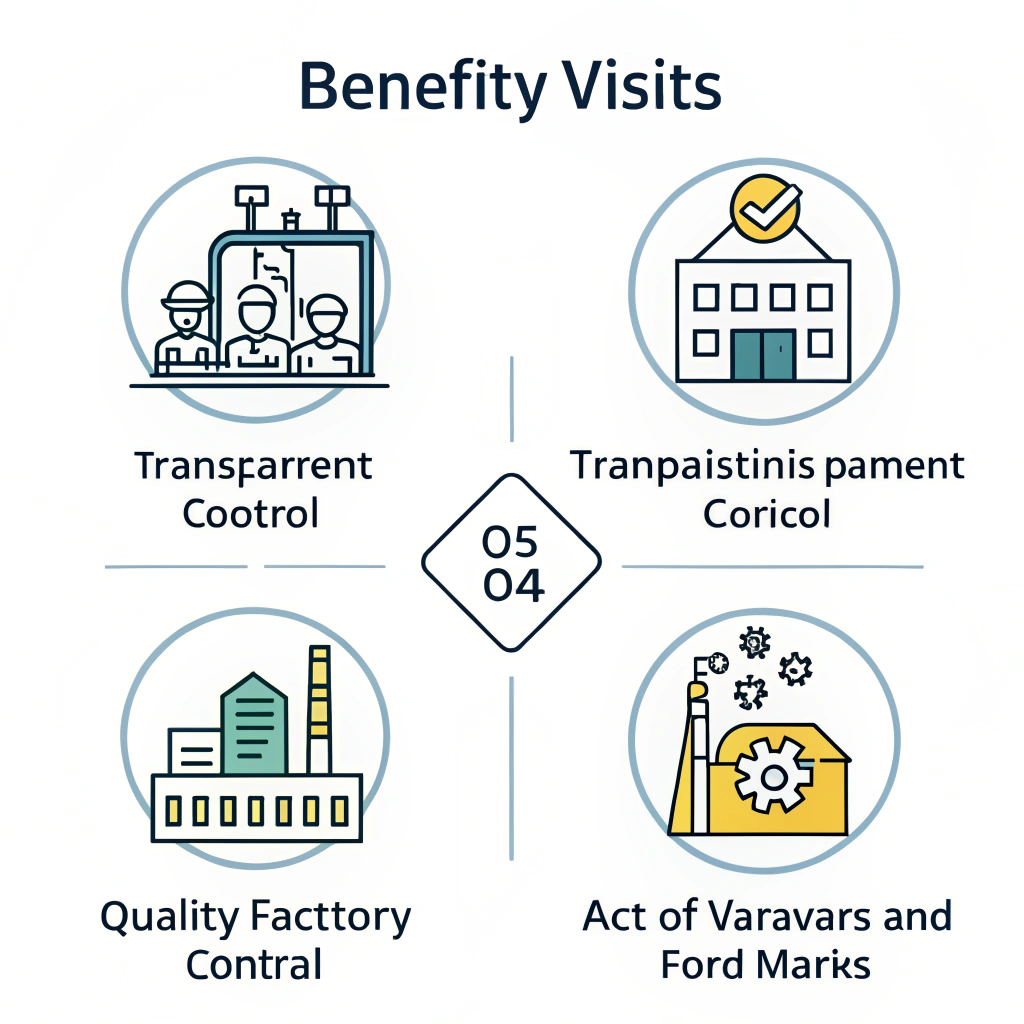

Factory visits provide tangible benefits across various dimensions. Below is a table summarizing the key advantages:

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Quality Control | Directly assess production and material quality, minimizing risks of sub-standard outputs. | Improved product reliability |

| Supplier Transparency | Witness first-hand the factory environment, operational processes, and turnaround times. | Better supplier trust and relationship |

| Customization Verification | Ensure that specialized requirements like custom printing, hand grip logos, etc., are met accurately. | Tailored product offerings |

| Real-Time Problem Solving | Address production or process issues on the spot with management and technical teams. | Faster resolution and process improvements |

| Data-Driven Decision Making | Gather qualitative and quantitative data for performance benchmarking against industry standards. | Informed procurement strategy |

Each of these advantages underscores why a well-planned factory visit can be an integral part of your due diligence process.

When evaluating whether to schedule a factory visit, it’s important to balance the potential benefits with the associated costs. Here are some considerations to guide your decision-making:

-

Budget and Time Commitment:

Weigh the travel costs against the expected improvements in quality and consistency. Factor in travel time, lodging, and local transport expenses. -

Risk Mitigation:

A comprehensive supplier audit4 is an effective risk management tool. Identify specific issues that could affect your supply chain and factor in the frequency of production issues when deciding on the visit duration. -

Supplier History and Reputation:

For long-standing relationships, the added value of a factory visit might be lower if recent performance trends are consistently positive. However, new suppliers or those with recent performance deviations warrant closer scrutiny. -

Custom Requirements & Specifications:

If your product requires intricate customizations—such as bespoke printing, specific hand grip designs, or fluid material changes—a visit can help align expectations and reduce the chance of errors. -

Production Scale and Flexibility:

Evaluate the facility’s capacity to handle both small-batch custom orders and larger production runs. Observing the flexibility of production lines can provide insight into how the supplier might respond to varying order volumes. -

Communication and Language Barriers:

When working with factories across different languages and cultures, ensure that communication channels are as clear as possible. On-site visits help bridge any misunderstandings that remote communications might miss.

A careful cost-benefit analysis along these lines will help in determining whether a factory visit offers a valuable return on investment.

Many leading brands have reaped significant benefits from direct factory engagements. Consider the following insights drawn from industry experiences:

• Enhanced Quality Through Transparency:

Brands like Reebok have reported that regular factory visits helped them align quality control expectations with suppliers. By observing production directly, they could negotiate process improvements that reduced defect rates by more than 15%.

• Customization and Agility:

Companies working with partners such as Hirostar noted that a detailed audit of production lines enabled quicker turnarounds on custom orders. This agility helped them launch limited-edition products without sacrificing quality.

• Strengthened Supplier Relationships:

Establishing a personal rapport during factory visits builds long-term partnerships. Suppliers are more willing to invest in process improvements, knowing that their clients are committed to maintaining a close oversight. This relational trust often paves the way for flexible negotiation on pricing, delivery schedules, and even exclusivity deals.

These examples underline the practical benefits of factory visits by linking them with documented improvements in product quality and supplier cooperation.

To maximize the benefits of your visit, consider using the following best practices:

-

Pre-Visit Preparation:

- Develop a checklist covering critical aspects of production, ranging from raw material sources to final assembly.

- Confirm the availability of key personnel such as quality control managers and production supervisors.

- Research the supplier’s previous performance and any regulatory certifications they have.

-

On-Site Audit Approach:

- Begin with a guided tour by a knowledgeable factory representative, ensuring that all areas of production are covered.

- Ask to see batch test results, material certifications, and previous quality inspection reports.

- Engage in walk-through discussions about process bottlenecks, equipment maintenance, and any historical challenges the factory has faced.

-

Post-Visit Analysis:

- Create an audit report summarizing your findings with both qualitative remarks and quantitative data.

- Highlight any red flags or areas that require further discussion.

- Schedule a follow-up call or meeting with factory management to clarify doubts or plan for corrective actions if needed.

A structured approach not only boosts the overall effectiveness of a factory visit but also facilitates a smoother transition from supplier evaluation to long-term operational excellence.

Evaluating the success of a factory visit is as important as planning it. Here are some key performance indicators (KPIs5) to consider:

• Reduction in production defects post-visit

• Improvement in on-time delivery rates

• Enhanced responsiveness to custom order modifications

• Cost savings achieved through process improvements

• Strength of the supplier relationship as indicated by open communication and transparency

These KPIs can be integrated into your supplier evaluation frameworks, ensuring continuous improvement in your supply chain. A regular review of these indicators will prepare you for subsequent strategic decisions regarding supplier engagements.

In the realm of padel racket manufacturing, a factory visit is not a mere inspection—it’s an opportunity to fortify your supply chain, ensure compliance with quality standards, and foster innovation through custom production practices. The insights provided above suggest that the benefits of a well-planned on-site visit often outweigh the travel investments, particularly when precision and consistency are non-negotiable aspects of your production strategy.

For procurement managers and brand owners looking to mitigate risks and boost operational efficiency, consider scheduling regular factory visits. Prepare meticulously, focus on key performance indicators, and use the outcomes to drive a more strategic, data-backed supplier partnership. In doing so, you not only enhance the quality of your products but also build a robust foundation for long-term industry success.

Q1: What are the main benefits of visiting a padel racket factory?

A: A factory visit offers significant benefits such as improved quality control, transparency in production processes, better alignment on customized orders, and the opportunity to build stronger supplier relationships.

Q2: How can on-site audits reduce manufacturing risks?

A: On-site audits allow procurement managers to directly assess the production environment, verify material quality, and ensure that the supplier’s procedures adhere to agreed standards, thus reducing the risk of defects and production delays.

Q3: What should be included in your pre-visit checklist for a supplier audit?

A: A pre-visit checklist should cover key aspects such as material sourcing, production processes, quality control measures, past performance data, and the availability of crucial personnel like quality managers or production supervisors.

-

Quality Control: Click to read an in-depth guide on implementing quality control measures in manufacturing environments, enhancing product reliability and compliance. ↩ ↩ ↩2

-

Customization: Click to explore strategies for managing and verifying product customization in manufacturing to meet specific client requirements. ↩ ↩

-

3k: Click to understand the significance of carbon fiber grades like 3k, detailing material composition and its impact on product performance. ↩ ↩

-

Supplier Audit: Click to learn how structured supplier audits can mitigate risks and ensure a robust evaluation of manufacturing processes and quality standards. ↩ ↩

-

KPIs: Click to discover key performance indicators (KPIs) vital for assessing manufacturing efficiency and overall supplier performance. ↩ ↩