Quick Answer: High-performance padel rackets offer distinct benefits, from advanced materials like carbon fiber1 and fiberglass to a variety of design shapes (Diamond, Round, Teardrop) that meet specific play styles and procurement requirements. Our detailed comparison and production insights help you make informed sourcing decisions.

In today’s competitive sports equipment industry, procurement managers and retail buyers must balance several criteria when sourcing high-performance padel rackets. The main challenges include evaluating technical specifications, durability under regular use, production quality, and customization potential. With evolving market demands and manufacturing techniques improving rapidly, it is crucial to compare products effectively to ensure optimal performance in-store and customer satisfaction.

Our approach at NEX Padel integrates advanced production techniques, strict quality control, and a wide range of customization options. These factors contribute significantly to the overall value of our padel rackets.

When sourcing equipment, comparing design and material differences is essential. Our padel rackets come in three primary shapes: Diamond, Round, and Teardrop. These designs cater to different player strengths and game styles, and each has unique advantages. Below is a structured comparison of these types to help you navigate their distinctions.

| Racket Type | Key Design Feature | Target Player Style | Material Options | Customization Options |

|---|---|---|---|---|

| Diamond | Pointed shape & high balance for power-driven strokes | Offensive players needing aggressive hits | Fiberglass, 3k/12k/18k carbon fiber | Full custom shape, logo print on frame and hand grip |

| Round | Circular shape providing balanced control and maneuverability | Defensive players seeking consistency | Fiberglass, various carbon fiber grades | Custom grip colors, personalized handle covers |

| Teardrop | Hybrid shape blending power and control | Versatile players with mixed strategy | Combination of fiberglass and high-performance carbon fiber | Variable weight distribution, design and color options |

This table presents the core differences in design focus, material composition, and customization possibilities. With these comparisons, procurement managers can match product features with their store’s customer base.

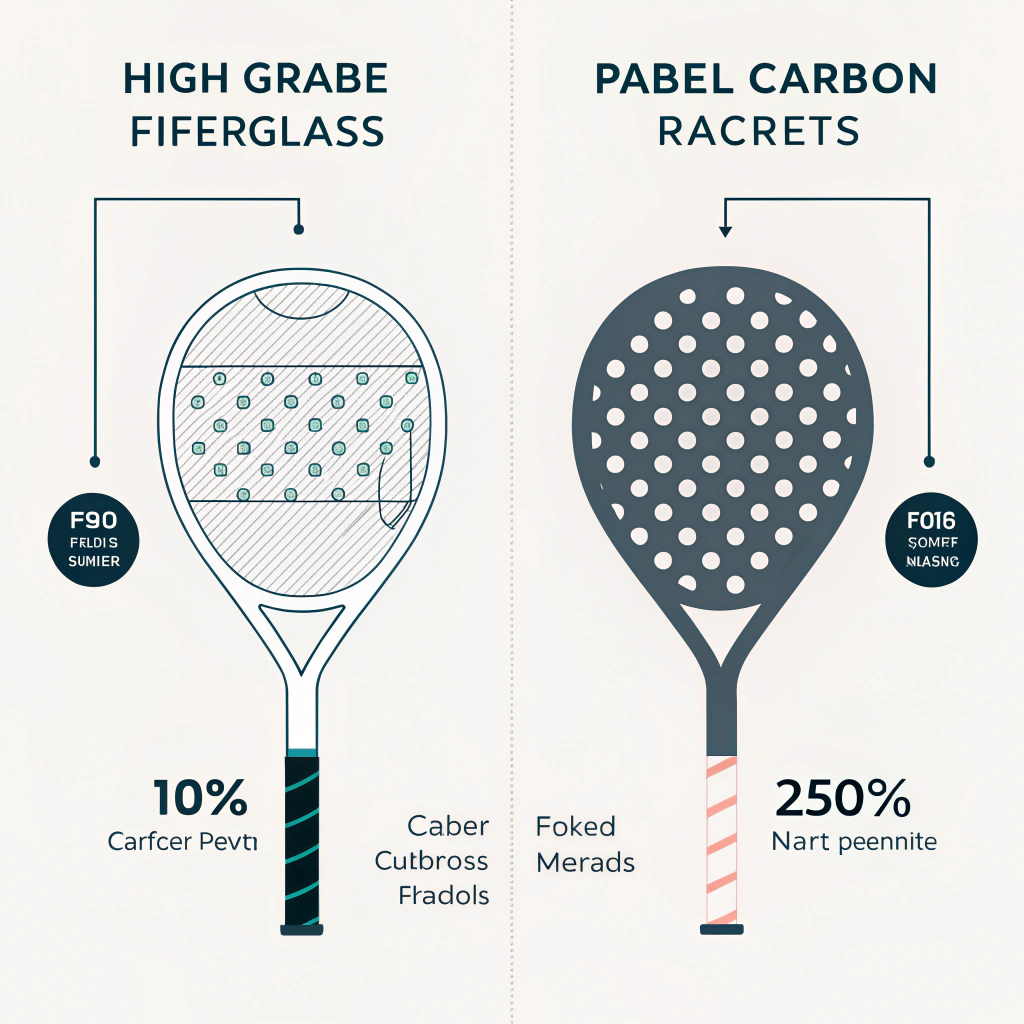

The choice of materials is crucial for performance, durability, and cost efficiency:

-

Carbon Fiber Technology: At NEX Padel, we utilize various grades of carbon fiber – including 3k, 12k, and 18k options. Each grade offers a different balance between strength, weight, and stiffness. Higher grades (12k and 18k) are ideal for top-tier performance while maintaining manageable weight, and they are favored by players seeking both control and power.

-

Fiberglass Integration: Fiberglass is used to offer an excellent price-to-performance ratio and improved durability. It provides flexibility without compromising racket structure. This is particularly beneficial for players who demand consistency in control throughout a match.

Efficient production techniques ensure that each material meets our strict quality standards, resulting in rackets that can endure intense gameplay while retaining their performance characteristics.

Customization plays a pivotal role in today’s B2B market and is one of the hallmarks of our offering. Retail buyers value the ability to present differentiated products that align with their brand identity. Here are some key customization aspects:

-

Shape and Design: Customers can choose from our standard Diamond, Round, and Teardrop shapes or even request a fully custom form tailored to specific play styles.

-

Color and Logo Imprinting: Beyond the basic color options, our production process supports custom prints both on the racket frame and the hand grip. This level of personalization enhances brand recognition and consumer loyalty.

-

Additional Accessories: We also provide customization for accessories like hand grips and handle covers, ensuring full brand cohesion across product lines.

These customization options allow you, as a buyer, to stock products that are unique to your market and reflect the precise needs of your clientele, setting your offerings apart from competitors.

Our manufacturing processes are optimized for both quality and speed, addressing two crucial procurement needs—reliable performance and timely delivery.

-

Rapid Prototyping2 and Sampling: We pride ourselves on quick sample production, allowing clients to test and evaluate design modifications without long lead times.

-

Strict Quality Assurance3: Each stage of production is monitored to meet international standards. Durability tests and performance evaluations ensure that every padel racket arrives in peak condition. Our rigorous quality management process includes stress tests for material integrity and impact resistance, catering specifically to professional play conditions.

-

Scalability4 in Production: Whether you require a small batch for market evaluation or a large-scale order for national distribution, our production line can quickly adapt. This scalability minimizes inventory waiting times and maximizes return on investment.

Ensuring product consistency and adherence to manufacturing timelines is critical for procurement managers, and our tailored approach directly addresses these priorities.

When evaluating high-performance padel rackets, here are some critical sourcing criteria to consider:

- Durability: Look at the specific materials used. High-quality carbon fiber and fiberglass ensure that the racket sustains high impact while maintaining its structural integrity.

- Weight and Balance: Different materials contribute to the overall weight and balance of the racket. Understanding how these factors affect play style is essential.

- Shape for Specific Play Styles: Each design—Diamond, Round, and Teardrop—offers aspects tailored to power or control. Evaluate how the design aligns with the needs of your target customer.

- Customization Options: A racket that offers extensive customization allows you to cater to niche market segments.

- Lead Times: Efficient production and shorter delivery times contribute significantly to inventory management. Verify that your supplier can meet your order deadlines.

- Consistency: Regular quality control and production standard adherence are essential to minimize returns and maintain customer satisfaction.

- Cost vs. Performance: Although high-performance rackets often command a premium price, it is important to ensure that the cost reflects the advanced production techniques and material quality.

- Bulk-Ordering Benefits: Many suppliers, including NEX Padel, offer attractive pricing structures for large orders, making them ideal for retailers seeking competitive margins.

- Supplier Experience: An experienced manufacturer with a record of supplying premium brands (e.g., Hirostar, Reebok, Starvie) can be a reliable partner.

- After-Sales Support: Ensure that your supplier offers robust after-sales support in case of quality issues or design modifications.

By weighing these criteria, procurement managers can confidently select padel rackets that will meet both performance expectations and market demands.

Align your sourcing strategy with these insights to maximize the performance and market appeal of your rackets. Here are some recommended next steps:

- Conduct In-House Testing: Obtain a sample of each type—Diamond, Round, and Teardrop—to assess handling, performance, and customization options in real-world conditions.

- Consult with Suppliers: Engage with manufacturers who offer robust customization and proven production quality. Inquire about lead times, quality control processes, and after-sales support.

- Market Analysis: Consider your target market’s needs when selecting a product. The balance between cost, quality, and customization is crucial.

- Evaluate Long-Term Partnerships: Choose suppliers with not only competitive pricing but also a commitment to innovation and quality assurance.

By integrating these practices into your procurement process, you can source padel rackets with confidence that they will satisfy both performance standards and consumer demands.

Q: How do different materials (carbon fiber vs. fiberglass) impact padel racket performance?

A: Carbon fiber provides a stiffer, more powerful play with effective energy transfer, particularly in high-grade forms (12k/18k) for elite performance, while fiberglass offers greater flexibility and durability at a more accessible price point.

Q: What customization options can be applied to high-performance padel rackets?

A: Customization may include modifying racket shapes (Diamond, Round, or Teardrop), personalized color schemes, logo imprinting on the frame and hand grip, and even custom handle covers to deliver a unique product look and performance.

Q: How do different padel racket types (Diamond, Round, Teardrop) cater to various play styles?

A: Diamond rackets emphasize power and aggressive plays, Round rackets focus on control and maneuverability, and Teardrop rackets offer a balanced blend of both power and versatility, allowing players to adapt to multiple game strategies.

-

carbon fiber: Read the linked article to understand the properties, production methods, and performance benefits of carbon fiber in sports equipment manufacturing. ↩ ↩

-

Rapid Prototyping: Click to learn how rapid prototyping accelerates product testing and design iteration for high-performance sports equipment. ↩ ↩

-

Strict Quality Assurance: Discover how rigorous quality assurance processes ensure product reliability and performance under demanding conditions. ↩ ↩

-

Scalability: This article explains how scalable production processes can manage varying order sizes while maintaining consistent quality. ↩ ↩