Quick Answer: When ordering padel racket samples, procurement managers should evaluate quality standards, detailed customization options, and efficient production lead times to ensure that the sample aligns with both performance and branding requirements. This article provides a comparative guide on sample ordering processes, highlighting key technical specifications and practical advice to help you decide on the ideal manufacturing partner for your business.

For B2B buyers in the sports equipment industry, especially those dealing with padel gear, ordering product samples plays a crucial role in the procurement decision-making process. Padel racket samples1 are not merely trial products; they represent a commitment to quality, precision, and innovation that a manufacturer, such as NEX Padel, brings to the industry.

Before placing sample orders, procurement managers need to evaluate several factors:

- Product quality ensured through advanced production techniques.

- Customization options2 including full custom shapes, printing, and color matching.

- Delivery timelines that align with your market demands.

- Material specifications like the use of advanced carbon fiber types (3K, 12K, 18K) and quality assurance standards.

This article breaks down the process for ordering padel racket samples, compares key elements among top manufacturers, and offers practical tips to streamline your decision-making process.

Quality assurance3 is a top priority for any sports equipment procurement project. Padel rackets must be produced using materials that provide both durability and high performance. For instance, NEX Padel’s products range from glass fiber reinforcement to advanced carbon fiber4 structures, including 3K, 12K, and 18K variations. Each material grade offers specific benefits in terms of weight, stiffness, and performance on the court.

- Glass Fiber: Provides a balanced mix of durability and cost efficiency.

- Carbon Fiber Variants:

- 3K Carbon Fiber: Ideal for entry-level to intermediate performance.

- 12K and 18K Carbon Fiber: Offer increased stiffness, higher precision, and are typically used in professional-grade rackets.

Manufacturers use stringent testing protocols and certifications to ensure that every sample meets predefined performance metrics. Verification steps might include lab testing for material consistency, stress testing for impact resistance, and real-world simulations to assess playability.

Customization is a significant advantage when ordering samples. B2B buyers need to ensure that the manufacturer can replicate the precise specifications of the final product. Key customization options include:

- Racket shapes: Options such as Diamond, Round, and Teardrop, as well as fully custom shapes based on precise requirements.

- Visual Branding: Custom printing and color matching can help align the product with your brand identity. Manufacturers like NEX Padel offer personalized printing options, including logo placement on the racket face, hand grip, and handle cover.

- Accessory Customization: Beyond rackets, the custom order process can extend to padel balls, where options such as 45% wool and 57% wool provide different performance profiles.

Thoroughly analyzing the sample allows you to assess not only the aesthetic fidelity of the product but also the underlying quality. It is vital to request detailed product specifications along with the samples to compare them against your procurement standards.

Efficiency in production is critical for maintaining your supply chain. Lead time5—defined as the period from sample order placement to delivery—directly affects market planning and inventory management. Factors influencing lead time include:

- Initial Design and Prototype Phase: Once your sample request is submitted, the manufacturer will assess your design needs. Custom designs may require additional consultation and prototyping.

- Production Run and Material Sourcing: High-performance materials like premium carbon fibers might have longer sourcing times but guarantee superior product performance.

- Quality Checks and Testing: Every sample undergoes a series of tests to ensure it meets both internal and external standards, which might add to the total production time.

- Delivery and Logistics: Efficient logistics and distribution partnerships help reduce delivery times, ensuring that you receive the sample in a timeframe that supports your market schedule.

Manufacturers with streamlined order processes and robust logistics networks can provide faster turnaround times without compromising quality, crucial for businesses needing to move quickly in competitive markets.

When comparing potential suppliers for padel racket samples, it is useful to evaluate how each manufacturer addresses the following criteria:

| Criteria | NEX Padel | Example Competitor A | Example Competitor B |

|---|---|---|---|

| Material Quality | Uses high-performance 3K, 12K, and 18K carbon fiber; glass fiber options available | Offers similar materials but with limited carbon fiber grades | Primarily uses glass fiber with limited carbon options |

| Customization Options | Custom shapes (Diamond, Round, Teardrop) with full customizations including logo printing on hand grip and cover | Limited to fixed shapes and minor branding options | Customization available only for color and basic logo placement |

| Production Efficiency | Fast sampling process with comprehensive quality checks and flexible scheduling | Moderate lead times; fewer checkpoints during production | Longer lead times due to outsourced production steps |

| Quality Assurance | Stringent testing protocols covering material tests and performance simulations | Standard quality checks without extensive testing | Basic quality control with limited performance simulation |

| Supply Chain & Logistics | Integrated logistics ensuring timely delivery with extensive market reach | Rely on third-party logistics with variable delivery times | Limited distribution network affecting delivery schedules |

This table highlights the comparative strengths and limitations. While some competitors might offer cost advantages, factors like material precision, production efficiency, and robust quality checks are crucial when selecting a manufacturer for sports equipment. NEX Padel’s comprehensive approach minimizes risk and uncertainty, ensuring that when you order padel racket samples, they fully reflect the potential of final production runs.

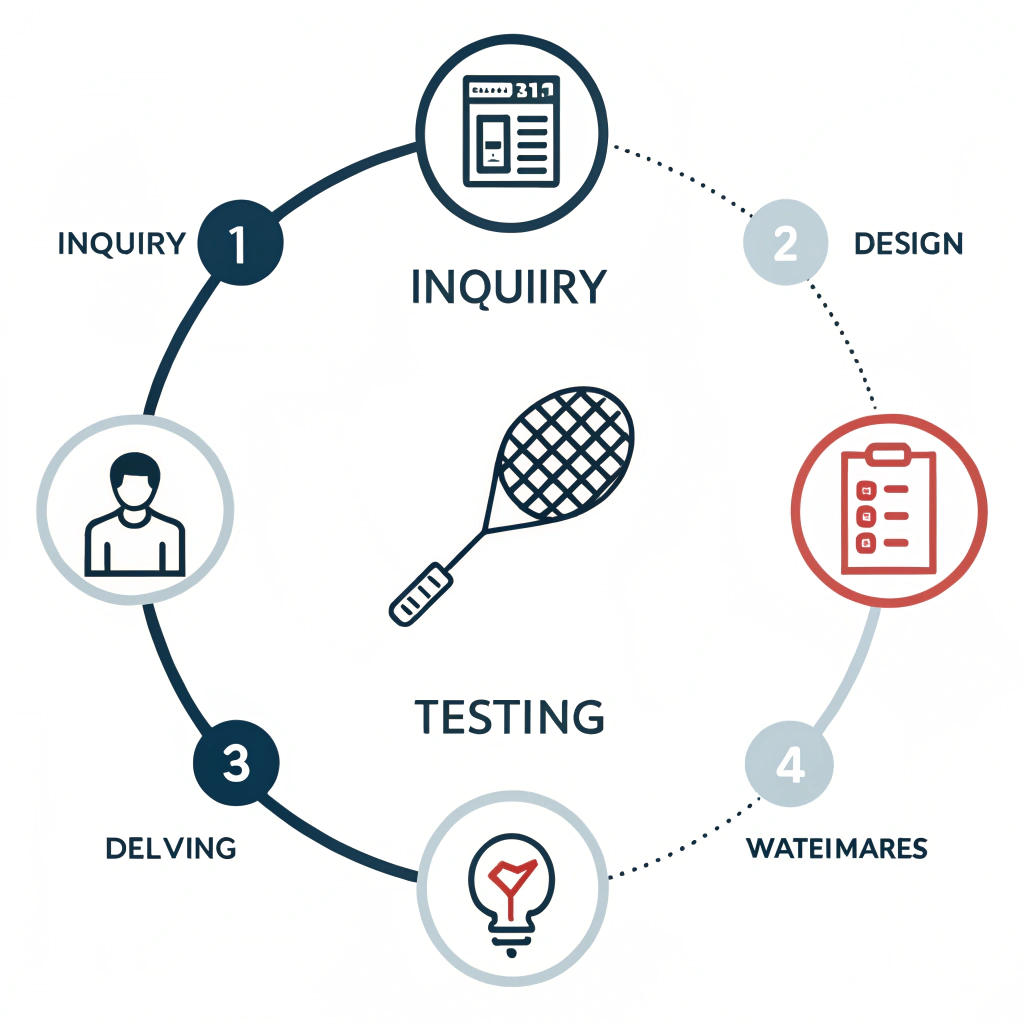

A well-structured sample ordering process can be broken down into specific, manageable phases. Understanding these phases can help procurement managers articulate their needs better and set precise expectations with the supplier.

-

Step 1: Inquiry Submission

Begin by contacting the manufacturer. Provide detailed specifications including desired material type, design features, and any necessary customizations. -

Step 2: Consultation and Consultation Call

Engage in a consultation to discuss technical requirements and address any queries. This step helps tailor the sample to immediately reflect your final product expectations.

-

Step 3: Design Proposal

The manufacturing team presents design proposals based on your inputs. This might include CAD drawings or mock-up visuals to ensure alignment. -

Step 4: Prototyping and Initial Manufacturing

A prototype is manufactured that serves as the first tangible representation of your product. During this phase, specialized tests such as stress-testing and balancing tests on the racket are often performed.

-

Step 5: Quality Assurance and Testing

Rigorous quality tests ensure that the prototype meets the technical specifications. Testing includes material integrity tests to ensure hardness, flexibility, and resistance. -

Step 6: Feedback and Modification

Once the sample is delivered, procurement managers can evaluate its performance and aesthetic appeal. Any modifications or refinements are communicated to the manufacturer before proceeding to bulk production.

-

Step 7: Confirmation of Specifications

After any required changes, the final sample is approved as the standard for production. Detailed documentation on all specifications is shared to avoid any miscommunication. -

Step 8: Logistic Coordination and Delivery

The manufacturer finalizes the logistics, ensuring that the sample reaches you promptly. This includes coordination with shipping partners to track the delivery status.

Each of these phases is crucial for ensuring that the final product will meet or exceed market expectations. Clear communication, thorough testing, and detailed documentation minimize the chance of unexpected issues during the larger production run.

-

Demand Detailed Specifications: Always request detailed documentation on the materials, manufacturing processes, and quality control standards used during sample production. This documentation will be critical during final product assessments.

-

Plan for a Feedback Cycle: Ensure that the manufacturer is supportive of a feedback loop. This allows you to request adjustments, helping you achieve an exact match to your branding and performance requirements.

-

Evaluate Production Efficiency: In industries like sports equipment, lead times can be a deciding factor. Ask manufacturers for historical data about their delivery timelines to gauge their reliability.

-

Leverage Case Studies and Data: Request case studies or recent examples from the manufacturer. This can provide insights into their production capabilities and how well they handle custom orders. Data-backed insights help build trust in their processes.

-

Consider Logistic Support and Scalability: Effective logistics demonstrate a manufacturer’s strength in supply chain management. Ensure your chosen manufacturer can scale production based on your demand forecasts.

-

Make Use of Comparative Checklists: Create a checklist based on the discussed criteria (material quality, customization options, production efficiency, quality assurance, and logistics). This checklist will serve as a reference point when comparing multiple suppliers.

Below is an example checklist table tailored for sample orders:

| Evaluation Point | Details to Consider |

|---|---|

| Material Quality | Carbon fiber grade, glass fiber standards |

| Customization | Range of designs, logo printing, color options |

| Production Timeline | Average lead time from inquiry to delivery |

| Quality Checks | Testing methods, certifications provided |

| Logistics | Shipping methods and reliability |

Implementing these best practices can empower you to make a confident and informed decision when selecting the right manufacturer for your padel racket samples.

Given the expanding market for padel equipment, ensuring that your manufacturing partner can deliver high-quality, customizable samples on time is essential. The sample ordering process is not only a test of product quality but also of the manufacturer's ability to handle technical details and adjust to nuanced requirements.

To summarize:

- Quality and Material Integrity: Focus on suppliers that use advanced material specifications.

- Customization and Flexibility: Choose manufacturers who offer extensive customization, ensuring the sample mirrors the final product.

- Efficient Lead Times: Factor in production and logistic efficiencies to maintain supply chain responsiveness.

- Data-Driven Decision Making: Utilize comparative checklists and case studies to verify the manufacturer’s reliability.

NEX Padel stands out as a partner who meets these criteria. Our expertise in high-performance padel racket manufacturing, combined with a robust quality assurance process and flexible customization options, ensures a seamless transition from sample to final production. We have a proven track record with well-known brands like Hirostar, Reebok, and Starvie, which underscores our commitment to excellence.

Procurement managers are encouraged to initiate dialogue with manufacturers, request comprehensive sample documentation, and use the insights from this guide to benchmark supplier performance effectively. By doing so, you'll harness both production innovation and market agility, empowering your business decisions in a competitive sports equipment industry.

Q: How long does it take to receive a padel racket sample?

A: Typically, the sample ordering process—including design consultation, prototyping, quality testing, and logistics—can take anywhere from a few days to several weeks, depending on customization complexity and materials used.

Q: What customization options are available for padel racket samples?

A: Manufacturers often offer options such as different racket shapes (Diamond, Round, Teardrop, or fully custom), personalized printing and color schemes, and even custom accessories like hand grips and handle covers to align with your branding.

Q: What factors should B2B buyers consider when ordering padel racket samples?

A: Buyers should evaluate material quality (e.g., carbon fiber grades), production efficiency, quality control measures, customization flexibility, and logistic capabilities to ensure the sample aligns with both performance standards and product specifications.

-

Padel racket samples: Read this article to understand the importance of product sampling in verifying quality, design, and performance before proceeding with bulk production. ↩

-

Customization options: Discover how manufacturers tailor products to meet precise specifications and branding requirements, ensuring a seamless transition to full-scale production. ↩

-

Quality assurance: Click to learn about comprehensive testing methods and certifications that validate product durability and performance in competitive markets. ↩

-

Carbon fiber: Explore detailed insights into the types and grades of carbon fiber used in high-performance sporting goods and their impact on product strength and weight. ↩

-

Lead time: Understand how lead time influences production planning and supply chain management, ensuring timely delivery and market competitiveness. ↩