Yes — pick a manufacturer who proves capability across materials (from fiberglass1 to 3k/12k/18k carbon2), fast and transparent sampling3 and lead times, low MOQ4 options, strong QC and testing5, and verifiable brand references. Below is a practical, side-by-side decision guide to shortlist and select an OEM padel racket partner, plus how NEX Padel meets each procurement requirement.

Choice problem: you need a reliable OEM/ODM padel racket partner that can deliver consistent quality, customization, and predictable logistics. This guide compares the core decision factors and gives clear recommendations for the contract, sampling and first production run.

- Quick overview — what procurement teams care about (and why)

- Material range and finish options — affects performance claims and price tiers.

- Racket shapes and structural options — Diamond, Round, Teardrop and custom shapes.

- Customization — surface printing, color matching, handle and grip branding.

- Sampling policy and lead time — speed to prototype confirms manufacturing readiness.

- MOQ and pricing tiers — flexibility for private-label launches.

- Production capacity and on-time delivery (OTD) metrics — prevent launch delays.

- QC, testing and certifications — ensures consistent playability and reduces returns.

- Client references and past OEM experience — evidence of trust by known brands.

- Core differences at a glance

- Use this quick table to compare suppliers in your shortlist during RFP evaluation.

| Decision factor | What to ask / measure | Benchmark to expect from a reliable partner |

|---|---|---|

| Material capability | Can you make frames with fiberglass, 3k/12k/18k carbon cloth? What layups and foam cores? | Full range: fiberglass entry -> 3k balanced -> 12k/18k high-end; multiple core options (EVA, POE). |

| Shape & tooling | Support for Diamond / Round / Teardrop and custom molds? Tooling cost and lead time? | Existing molds for three shapes; custom mold 25–45 days tooling. |

| Sampling speed | How fast for a branded prototype? | 7–21 days depending on print and custom tooling. |

| MOQ & pricing | MOQ per SKU for custom printing? Price breaks? | MOQ 50–200 units for standard; sample unit available; tiered pricing at 500/1k/2k+. |

| Quality control | Incoming raw material checks, in-line QC and final testing? Defect rate KPI? | IQC + IPQC + FQC; target defect rate <1.0%; inspection reports with photos. |

| Capacity & delivery | Monthly production capacity and OTD % | 10k–50k rackets/month (depends on lines); OTD >95% typical for established partners. |

| Certificates & testing | Can you support durability, balance, and CE requirements? | Lab test results: seam strength, surface adhesion, balance, impact tests; CE on request. |

| References | Known brand OEM clients | Transparent list: e.g., Hirostar, Reebok, Starvie (examples). |

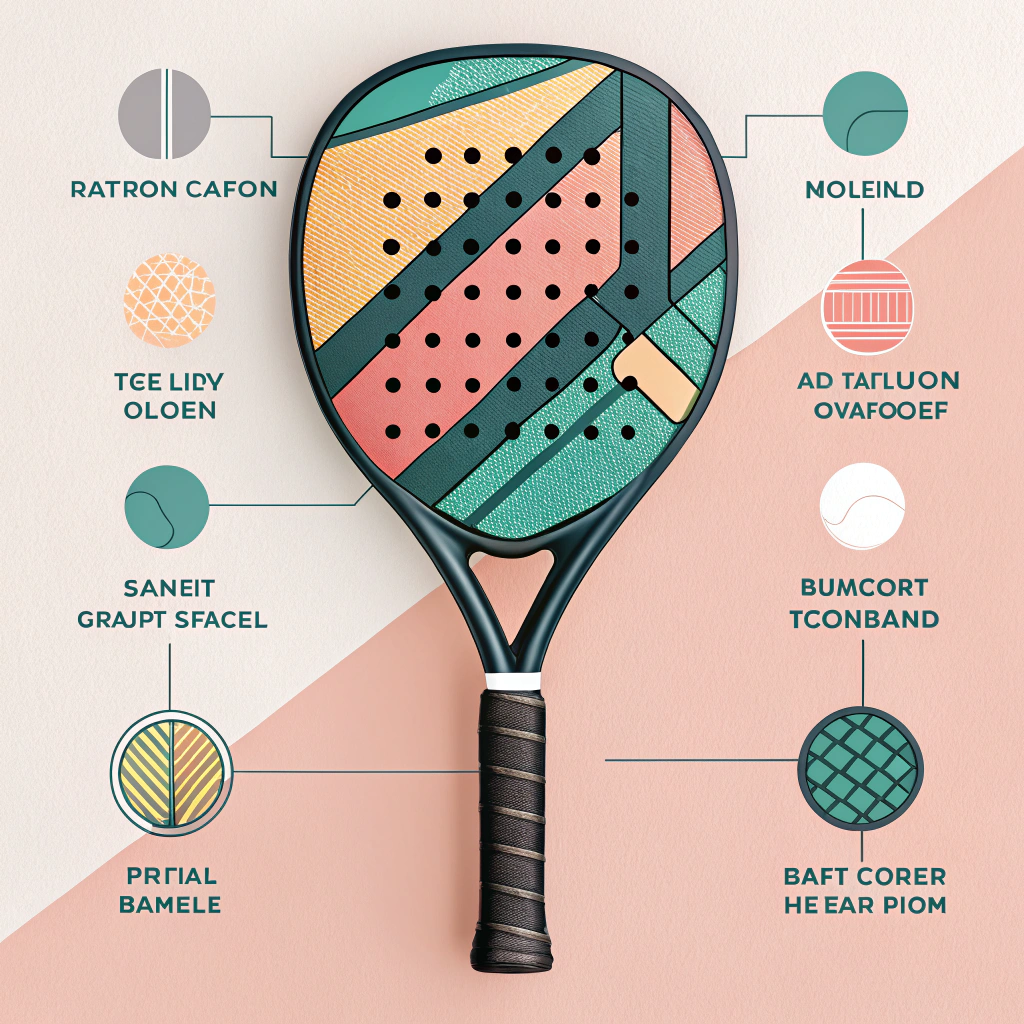

- Material and performance — what matters to product owners

- Fiberglass: cost-effective, more flexible. Good for entry-level and mid-range models where spin and comfort are prioritized over absolute stiffness.

- Carbon fiber (3k / 12k / 18k): increasing levels of stiffness, surface finish and visual texture.

- 3k carbon: typical woven pattern, good balance of stiffness and flexibility; preferred for mid-to-high performance rackets.

- 12k carbon: denser cloth, higher stiffness and improved impact resistance; used for more controlled, stable rackets.

- 18k carbon: very dense weave for premium models emphasizing power and durability.

- Core materials: EVA densities and POE variations control touch, power and durability. Suppliers should be able to provide durometer options.

- Surface finishes: matte vs glossy carbon, sandblasted fiberglass textures, UV-stable inks for branded prints.

Table — Material impact on performance (simple view)

| Material | Typical feel | Best for | Cost impact |

|---|---:---|---|---|

| Fiberglass | Softer, more forgiving | Beginners, affordable lines | Low |

| 3k carbon | Balanced stiffness, tactile | Mid to high performance | Medium |

| 12k carbon | Stiffer, stable | Advanced players, control | High |

| 18k carbon | Very stiff, durable | Premium power/control models | Highest |

- Customization & branding — what to verify in RFP

- Printing and color matching: Can they do Pantone matching? What printing methods (pad print, UV, full-surface sublimation)? Ask for Delta-E color tolerance.

- Handle & grip customization: logo embossing on butt cap, custom hand grip colors and materials.

- Packaging and accessories: custom boxes, swing tags, included grips, and whether padel balls can be bundled (45% wool or 57% wool options, pressurized tube packaging).

- Tooling ownership: who owns custom molds? Standard negotiation: tooling cost credited against MOQ or amortized.

- Sampling policy, lead times and typical timelines

- Request distinct timelines and costs:

- Off-the-shelf sample (existing SKU + branded print): 7–10 days.

- New colorway on existing mold: 10–14 days.

- New mold + new shape: 25–45 days for tooling + 7–10 days for sample production.

- Production lead time after sample approval:

- Small batch (MOQ–1k): 25–35 days.

- Medium batch (1k–5k): 30–45 days.

- Large orders: depends on capacity, often 45–60+ days with phased shipping.

- Shipping options and lead time impact: sea freight is slower (20–45 days), air freight for urgent.

Table — Typical timeline examples (for planning)

| Stage | Example | Time |

|---|---|---|

| Prototype (if existing mold) | Color + logo changes | 7–14 days |

| Prototype (new mold) | Tooling + sample | 35–55 days |

| Production (500–1,000 units) | After sample approval | 25–35 days |

| Production (2,000–5,000 units) | After sample approval | 30–50 days |

- MOQ and pricing — practical negotiation tips

- Ask for tiered price breaks (e.g., 1–499, 500–999, 1,000–4,999, 5,000+). This clarifies your margin at each scale.

- Negotiate tooling amortization: ask for tooling cost to be spread or credited if you commit to first production volume.

- Sample pricing: treat sample cost as credit against first bulk order (usual practice).

- Hidden costs to confirm: freight, custom packaging, private label printing plates, inspection fees.

- Quality control and lab testing — KPIs to request in RFP

- Production KPIs: target defect rate <1.0% (AQL), OTD >95%, and returns <1% in first-year shipment.

- QC steps to require in contract:

- IQC (incoming materials checks for cloth, foam, glue).

- IPQC (in-line checks for bonding, balance, hole drilling).

- FQC (final checks: weight, balance, visual defects, printing quality).

- Pre-shipment inspection: photos and a random sample inspection report (third-party inspection if required).

- Testing evidence: impact tests, balance and swing weight, surface adhesion, and aging tests for paints and grips. Ask for lab reports or to witness a test.

- Production capacity & reliability — what to verify

- Ask for monthly capacity by line and typical utilization. For example, a mid-sized factory might state 20k–40k rackets/month capacity with two production lines.

- Ask for recent OTD performance and examples of handling peak season (e.g., how they handled an order surge from a major brand).

- Verify backup plans: do they have alternate suppliers for critical raw materials (carbon cloth, EVA foam) to avoid single-source delays?

- Certifications, sustainability and compliance

- Certifications: ISO 9001 for quality systems is common. CE marking is relevant for European market claims.

- Environmental and chemical compliance: RoHS, REACH checks and avoidance of restricted phthalates in grips and packaging inks.

- Social compliance: BSCI / Sedex audits if your brand requires supplier social responsibility.

- How NEX Padel addresses procurement priorities (practical claims)

- Material range: full in-house or trusted supplier network for fiberglass and 3k/12k/18k carbon options, multiple core durometers.

- Shapes & tooling: standard Diamond, Round and Teardrop molds plus support for custom shapes; typical custom mold tooling lead time: 25–45 days.

- Sampling: rapid sample turnaround—existing-mold samples in 7–14 days; custom-mold prototypes 35–55 days.

- MOQ & pricing: flexible MOQs (sample units available; standard custom MOQ from 50–200 depending on finish). Tiered pricing and tooling amortization available.

- QC & KPIs: IQC/IPQC/FQC process; target defect rate <1.0% and OTD >95%. Provide inspection reports and third-party testing on request.

- Brand references: experienced OEM partner for Hirostar, Reebok and Starvie (examples) — ask for contactable references during RFP.

- Ball supply: partner factory supplies padel balls in 45% wool and 57% wool options with pressurized tubes to maintain pressure during transport.

- Turnkey options: support for private-label ready-to-sell kits (racket + carrying case + hand grip + ball pack + retail box).

- Contract and onboarding checklist (what to include in the PO)

- Technical pack and master sample approval clause (MSA).

- Tooling ownership and amortization clause.

- Sample credit clause (sample fees offset against first order).

- QC acceptance criteria and right to third-party inspection.

- Penalties for late delivery tied to OTD KPI.

- Warranty and defect replacement terms for first production.

- Final recommendation — how to shortlist and decide

- Shortlist 3 suppliers and run the same test:

- Request an off-the-shelf sample + 1 custom-branded sample (same printing spec).

- Ask for full costing: sample, tooling, MOQ pricing tiers, and lead times.

- Request a recent QC report, OTD figure and two client references (preferably one recognizable brand).

- Schedule a short factory audit or remote video walkthrough to verify production lines and capacity.

- Scoring model (simple):

- Technical capability 30%

- QC & testing 20%

- Lead times & logistics 15%

- Pricing & MOQ 15%

- References & trust 20%

- Next steps (practical, immediate)

- Draft a short RFP with the checklist above and send it to your top 3 candidates.

- Ask NEX Padel for: sample quote (SKU + custom print), tool costs estimate, MOQ tiers, and recent QC/OTD stats.

- If you want, request a joint sampling schedule and NDA so designs are protected before tooling.

Summary — what procurement should expect

- A reliable OEM partner must prove material flexibility, quick sampling, clear MOQs and pricing, rigorous QC and on-time delivery with client references. Use the short testing exercise above (same sample spec to 3 suppliers) to uncover which partner can deliver consistency and responsiveness. NEX Padel offers the full material range, fast sampling, flexible MOQ arrangements and proven OEM relationships — making it a practical candidate for private-label padel lines.

People Also Ask

Do expensive padel rackets make a difference?

Expensive padel rackets can improve specific performance aspects—stiffer carbon layups, better balance and finer surface finishes—but they don’t automatically improve a player’s skill. For procurement: expensive models matter when your brand targets advanced players or premium positioning. For mass-market or beginner segments, well-engineered fiberglass or 3k-carbon models deliver good value and player satisfaction at lower price points.

What are the best padel rackets made of?

The most common high-performance material is carbon fibre. Carbon offers a strong, light and stiff frame that improves power, control and durability versus fiberglass. Within carbon options, 3k is a common balanced choice; 12k and 18k are denser weaves used in higher-end models for increased stiffness and a different surface aesthetic. Core materials (EVA/POE) and layup design also significantly affect feel and playability.

(If you want these PAA answers expanded into FAQ cards for your site, I can format them for rich snippet optimization.)

-

fiberglass: Learn how fiberglass compares to carbon in cost, flexibility and player feel so you can specify the right material for entry and mid-tier SKUs and avoid over-spec’ing for mass-market segments. ↩︎ ↩

-

3k/12k/18k carbon: The linked resource explains weave counts, stiffness, visual finish and typical use-cases (3k = balanced, 12k/18k = higher stiffness/visual density), helping you justify material choices to product and marketing teams. ↩︎ ↩

-

sampling: Read about fast-sample workflows, typical sample lead times and how to structure sample credits in contracts to accelerate validation without excessive upfront cost. ↩︎ ↩

-

MOQ: This article outlines MOQ negotiation strategies, tooling amortization and tiered pricing models so procurement can forecast margins and scale thresholds before committing. ↩︎ ↩

-

QC and testing: The linked guide details practical QC steps (IQC/IPQC/FQC), lab tests to request and KPI thresholds (defect rate, OTD) to include in RFPs and contracts to reduce launch risk. ↩︎ ↩