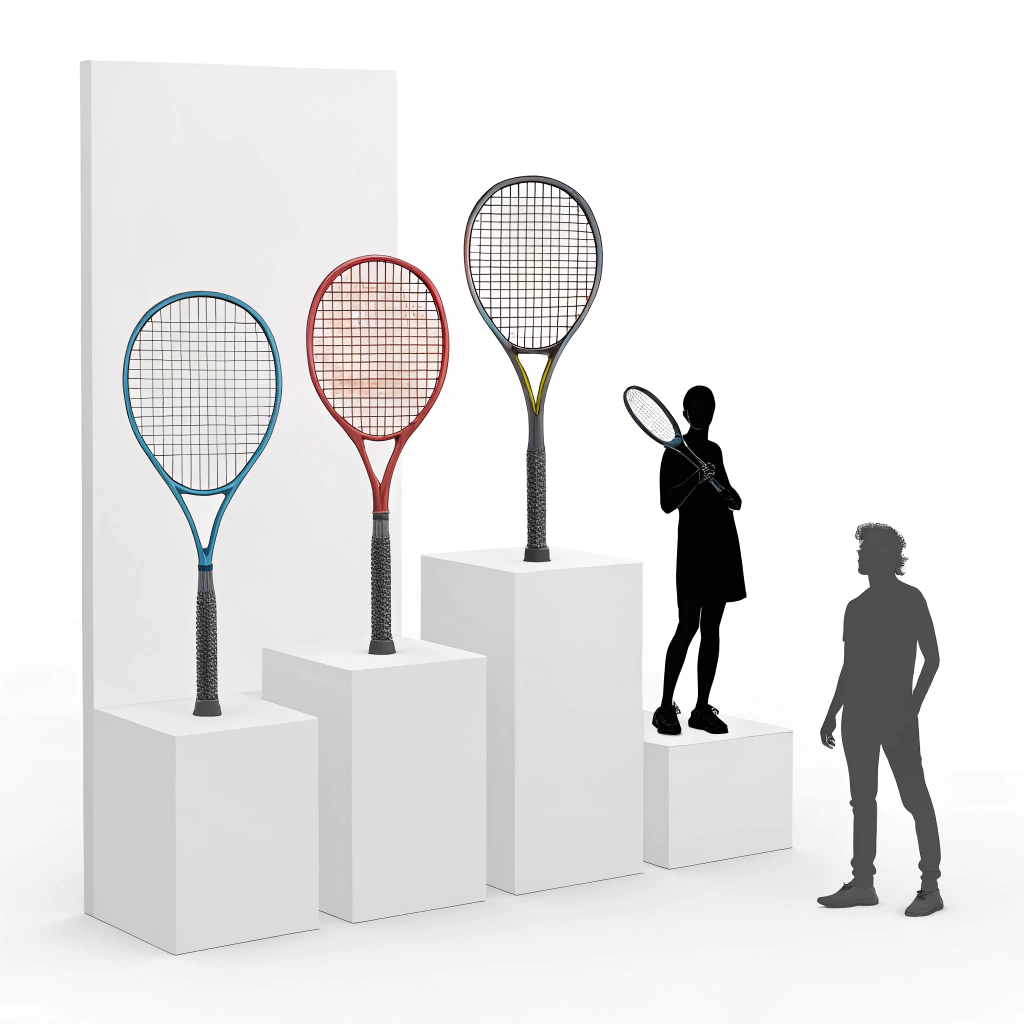

Quick answer — The best padel racket shape depends on the player profile: Round for maximum control and forgiveness (beginners, recreational players), Teardrop for balanced power and precision (intermediate to advanced players), and Diamond for maximum power and offensive play (advanced/aggressive players). Choose by matching sweet spot location, balance point1, and swing weight2 to your target customer segments, then confirm with OEM samples and measured swing-weight tests.

- The racket shape controls where the sweet spot sits and how weight is distributed. That, in turn, drives power, control, and maneuverability.

- Balance point (distance from the handle center to the point where the racket balances) and swing weight / inertia determine how fast a racket accelerates and how much power it transfers at contact.

- A head-heavy racket raises swing weight: more momentum into the ball (power) but reduced maneuverability and slower reactions at the net. A head-light racket lowers swing weight: faster recovery and better control.

- Core stiffness and surface material (EVA3 density, foam type, carbon vs fiberglass layup, and carbon weave such as 3K / 12K / 18K4) change energy return and feel. Stiffer cores + high-modulus carbon = more pop; softer cores + fiberglass = more touch.

- Round: low swing weight, sweet spot near the center, low inertia => control and forgiveness.

- Teardrop: medium swing weight, slightly higher sweet spot => balance of power and control.

- Diamond: high swing weight, sweet spot higher and toward the head => maximum power but smaller margin for error.

Below is a practical comparison you can use when shortlisting shapes for customers or product lines.

| Shape | Sweet spot location | Typical balance | Player fit | Pros | Cons | OEM/Production notes |

|---|---|---|---|---|---|---|

| Round | Central, low | Head-light to even | Beginners, casual, coaches/academy multis | Very forgiving, easy control, ideal for learning technique | Less raw power for aggressive hitters | Easier to keep low swing weight tolerance; lower rejection rate; good for fiberglass/softer cores |

| Teardrop | Mid-high | Even to slightly head-heavy | Intermediate, club players, broad retail segment | Balanced power/control, wide market appeal | Less specialized — may not satisfy power-only or control-only niches | Popular for OEM mixes; allows varied layups (carbon/fiberglass) to tune feel |

| Diamond | High, toward head | Head-heavy | Advanced, power players, pros | Maximum power, weapon for offensive play | Smaller sweet spot; harder to control; quicker fatigue | Tight tolerances on balance and swing weight; higher QC sampling; often uses 12k/18k carbon layups |

- If you sell entry-level or academy packages: prioritize Round shapes with softer cores (low-density EVA), fiberglass surfaces for softer feel, and head-light balance to maximize injury-safe play and inclusive user experience.

- For mass-market or mid-tier lines aiming broad appeal: stock Teardrop models in multiple stiffness/layup variants (soft, medium, hard core; fiberglass, 3K carbon face) so retailers and demo players can pick by feel.

- For performance or pro-level SKUs: offer Diamond shapes with high-modulus carbon (12k / 18k), stiffer cores, and optional weight customization (lead tape location) to fine-tune swing weight for aggressive players.

- Targeted balance point (±5 mm tolerance) and measured swing weight (±10 g·cm²). Ask for lab reports.

- Weight tolerance: ±3 g for retail models; ±1 g for pro models.

- Material spec sheet: face laminate (3K / 12K / 18K carbon, or fiberglass), core type & density (EVA/HR foam %), surface roughness (for spin).

- Print and color spec for full-custom models: pantone references, UV/solvent ink curing method.

- Grip and butt-cap customization options (logo emboss, grip size).

- Packing and ball compatibility (if bundling balls): specify wool % (45% vs 57%) and tube pressure packaging.

- Start with 3–5 prototype samples per shape/layup: one baseline plus varied core stiffness or face material. Field-test with representative players (beginner, club, pro).

- For initial commercial runs, request a pre-production batch of 50–200 units per SKU depending on channel:

- Pro-shop / premium retail: MOQ 100–200 to allow multiple sizes and weight options.

- Mass-market / academy: MOQ 200–500 to enable economies and promotional packs.

- Negotiate sample lead time vs tooling: expect 10–25 business days for quick prototypes; 4–8 weeks for full-color custom tooling and molds in organized factories.

- Ask OEM for swing-weight and balance point certificates with sample shipment to avoid iterations.

- Diamond rackets: maintaining a consistent high head-heavy balance requires strict resin control and precise layup placement. Expect a higher rejection rate if tolerances are loose.

- Teardrop rackets: versatile in layup, but small deviations in foam fill can shift sweet spot feel. Process control around core filling and cure cycles is essential.

- Round rackets: most forgiving; factories often achieve stable numbers quickly; good first-line option to test production partners.

Recommended QA tests to require:

- Static balance point measurement.

- Swing-weight test using a rotational inertia rig (provide target values).

- Impact and durability tests (10k-cycle fatigue tests).

- Surface adhesion and print durability tests (abrasion / UV).

- Batch sampling plan (e.g., 3% of production or minimum 10 units per SKU).

- Fiberglass face + soft EVA core: greatest touch and forgiveness — pair with Round shapes for beginners.

- 3K carbon face + medium EVA: classic mid-level option — ideal for Teardrop balance models.

- 12K / 18K carbon + hard EVA: stiffer, more power — pair with Diamond shapes for advanced players.

- Surface texture (rough/rougher carbon weaves) helps spin — useful for teardrop and diamond models marketed to technical players.

- Consider hybrid layups (mixed carbon + fiberglass) for price-sensitive markets that still demand performance.

- Can the factory hit weight and balance tolerances you require? (Ask for historical SPC / capability data.)

- What are lead times for prototypes, pre-production and mass production?

- MOQ thresholds and options for staggered deliveries or rollouts.

- Flexibility for full customization (shape, colors, logos, grip, packaging) and costs per change.

- Testing capabilities onsite or third-party lab partnerships and sample testing costs.

- Past references: which known brands has the OEM manufactured for? (At NEX Padel we OEM for brands like Hirostar, Reebok and Starvie — ask for references and similar SKUs.)

- Warranty and post-sale support: defective rate thresholds and RMA process.

- Retail starter pack for clubs / academies:

- Shape: Round

- Face: Fiberglass

- Core: Soft EVA

- Target weight: 355–370 g

- Balance: Head-light to even

- MOQ: 200–500

- Best-seller consumer line:

- Shape: Teardrop

- Face: 3K carbon or hybrid

- Core: Medium EVA

- Target weight: 360–375 g

- Balance: Even to slightly head-heavy

- MOQ: 100–300

- Pro/performance line:

- Shape: Diamond

- Face: 12K / 18K carbon

- Core: Medium-hard EVA

- Target weight: 365–380 g (offer multiple weight points)

- Balance: Head-heavy

- MOQ: 50–200 (higher QC)

- Map your customer segments (beginner, intermediate, advanced) and assign 1–2 shapes per segment.

- Request targeted tolerances (balance ±5 mm, weight ±3 g, swing-weight ±10 g·cm²) and insist on measurement certificates with samples.

- Order a matrix of samples: at least 3 shapes × 2 layups × 2 weight points = 12 samples for meaningful testing.

- Evaluate on-court with representative players and collect quantitative swing-weight/balance data plus qualitative feedback.

- Negotiate MOQ and phased deliveries after successful sample approval; include QC acceptance criteria in contract.

NEX Padel capabilities — quick note: we provide rapid prototyping, flexible layups from fiberglass through 3K/12K/18K carbon, and can customize shapes and printing. We also offer padel balls (45% or 57% wool) with pressurized tube packaging if you need bundled SKUs.

People Also Ask

Q: What shape is best for a padel racket?

A: There is no single “best” shape; choose by player profile. Round rackets favor control and forgiveness (best for beginners and recreational players). Teardrop rackets offer a compromise of power and control suitable for intermediate players. Diamond rackets maximize power and suit advanced, offensive players who can consistently hit the higher sweet spot.

Q: Do different padel rackets make a difference?

A: Yes. Shape, balance point, and swing weight change where the sweet spot sits and how energy transfers at impact, affecting power, control, and maneuverability. Materials and core stiffness further change feel and spin. Selecting the right combination lets you tailor rackets to specific customer segments and playing styles.

-

Balance point: Read to learn practical measurement methods, tolerance-setting for OEM specs, and how balance shifts affect swing-weight and player fit. (Back) ↩

-

Swing weight: Read to understand rotational inertia units, test rigs, target ranges for different player segments, and how to specify swing-weight tolerances in procurement. (Back) ↩

-

EVA: Read to get an overview of EVA foam types, density metrics, how core hardness affects feel and energy return, and what to request on material spec sheets. (Back) ↩

-

3K / 12K / 18K: Read to compare carbon weave counts, stiffness vs cost trade-offs, and typical performance characteristics to inform layup choices for each SKU. (Back) ↩

-

MOQ: Read to review common MOQ strategies, how MOQ impacts pricing and inventory risk, and negotiation tactics for phased rollouts or staggered deliveries. (Back) ↩