Padel racket thermoforming1 techniques involve heating a composite or plastic material—such as high-grade fiberglass2 or carbon fiber3—until it becomes pliable and then molding it into the precise shape of a racket. This rapid process, using heat, pressure, and controlled cooling, guarantees a final product that is both durable and high-performing.

In today’s competitive sports equipment market, manufacturers must continuously optimize production methods. This guide delivers an in-depth exploration of padel racket thermoforming techniques, specifically addressing the needs of manufacturing engineers and production managers who strive for higher efficiency and improved product quality in their own facilities. Our focus is on balancing technical precision with ease of implementation, derived from industry experience and advanced production standards.

Thermoforming is a critical process in creating the distinct shapes and designs of modern padel rackets. The procedure involves heating thermoplastic materials until they soften, allowing them to be formed into specific molds that define the racket’s characteristics. The primary benefits of thermoforming include:

• Increased Production Efficiency – Reduced cycle times due to rapid heating and cooling.

• Enhanced Durability – Uniform material consistency for stronger, longer-lasting rackets.

• Customizability – Ability to produce various shapes (Diamond, Round, Teardrop) and incorporate custom designs, colors, and logos.

• Cost-Effectiveness – Optimized material usage and minimized waste through precise control and automation.

For padel racket manufacturers like NEX Padel, utilizing advanced thermoforming techniques ensures that the final product is not only aesthetically pleasing but also meets the stringent performance demands of high-level play.

Understanding each stage of the thermoforming process is crucial for optimizing production and ensuring consistent quality. Here’s a breakdown of the typical production steps:

Before heat application, manufacturers must select the optimal material. Options often include different grades of carbon fiber3 (3k, 12k, 18k) or fiberglass2. The choice depends on the desired balance of weight, stiffness, and flexibility.

• Carbon Fiber: Offers superior strength and precision. Suitable for high-performance, custom designs.

• Fiberglass: Generally more forgiving during the molding process, which can be beneficial for complex shapes and cost control.

The selected material is uniformly heated using advanced industrial ovens or controlled heat blocks. Temperature parameters vary with the material composition:

• Carbon Fiber Composites: Require precise temperature control to avoid degradation.

• Fiberglass Mixes: Might allow slightly broader temperature ranges but still demand accuracy.

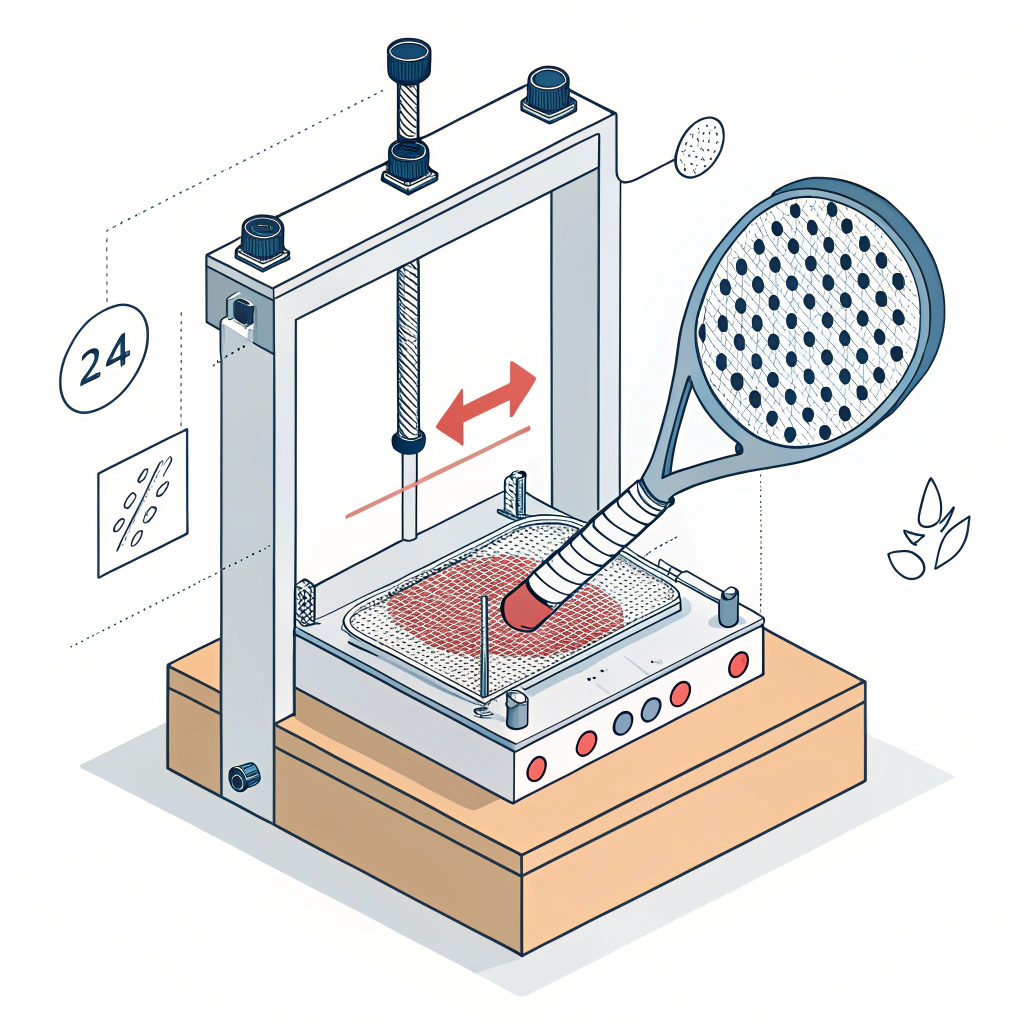

Once heated, the pliable material is pressed against a mold with specific dimensions. Automation in this phase ensures that the pressure is evenly distributed, and the material fills every part of the cavity. This step is where the racket shape is brought to life, either in a Diamond, Round, or Teardrop format.

After achieving the desired shape under heat and pressure, the material must be rapidly cooled to lock in its structural integrity. Cooling mechanisms may involve air, water, or a combination of both to solidify the structure while preventing deformations.

The final stage involves:

• Trimming excess material

• Polishing edges

• Quality assessment to ensure that every racket meets both aesthetic and performance standards.

Using thermoforming in padel racket production presents several advantages, though it is not without challenges. Below is a table summarizing the key factors:

| Aspect | Advantages | Challenges |

|---|---|---|

| Material Efficiency | Precise molding minimizes material waste. | High-end composites require careful handling to reduce waste. |

| Production Speed | Faster cycle times increase throughput. | Maintaining consistent temperature is critical for quality. |

| Product Durability | Uniform material yield improves structural strength. | Overheating can lead to material degradation. |

| Customization | Allows for unique designs and variations (custom print/logo). | Requires advanced machining for custom molds. |

| Cost-Effectiveness | Reduced material waste and optimized processes lower costs. | Initial setup and tooling investment can be high. |

The table shows how understanding each aspect of thermoforming can help manufacturers develop strategies that balance efficiency with quality.

To harness thermoforming fully for padel racket manufacturing, companies should consider several optimization strategies:

Implementing real-time temperature and pressure monitoring systems is essential. Automation ensures that variations are minimized throughout the cycle, reducing defects and enhancing product consistency.

• Sensors and IoT4: Integrate sensors to continuously monitor critical factors such as temperature, pressure, and cooling rates.

• Automated Adjustments: Use software algorithms that adjust heating duration and pressure settings based on real-time data.

Ongoing research into composite materials can lead to improvements in how materials respond during the thermoforming process. For instance, fine-tuning the resin matrix in carbon fiber composites can result in better energy absorption and durability.

• Custom Material Blends: Experiment with different resin formulations to achieve a balance between flexibility and rigidity.

• Enhanced Fiberglass Options: Explore fiberglass reinforcements that provide a lightweight alternative without compromising on strength.

Strict quality control protocols are the backbone of reliable production. Visual inspections, along with digital quality assurance systems, can catch issues early in the process.

• Non-destructive Testing5: Techniques like ultrasound or X-ray imaging help detect internal imperfections without damaging the racket.

• Regular Calibration: Scheduled checks on all thermal and pressure systems ensure consistent performance over prolonged production cycles.

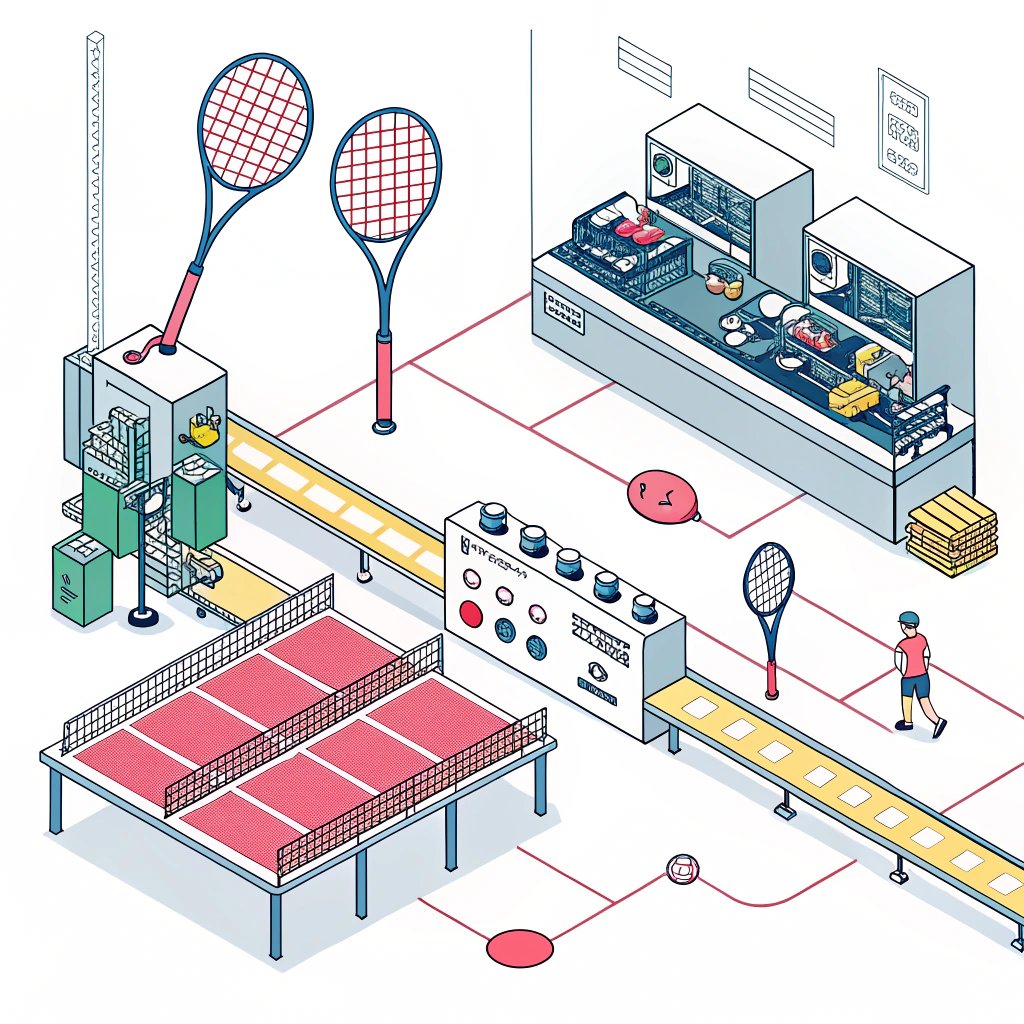

Consider a scenario where a leading manufacturer, similar to NEX Padel, implements advanced thermoforming techniques to improve both product quality and throughput. Here’s how they achieved success:

The manufacturing plant experienced inconsistencies in racket shapes, leading to frequent rejects and increased waste. The root cause was traced to variations in heating profiles and pressure application during the molding process.

- Advanced Sensors: Integrating temperature and pressure sensors helped monitor the conditions in real time.

- Automated Mold Pressing: Custom-designed molds with automated pressure control ensured the material filled the mold perfectly every cycle.

- Rapid Cooling Systems: Implemented air and water hybrid cooling systems minimized deformities during the cooling phase.

| Key Performance Indicator (KPI) | Before Optimization | After Optimization |

|---|---|---|

| Production Cycle Time | 120 seconds | 90 seconds |

| Reject Rate | 15% | 5% |

| Material Waste | 10% | 3% |

| Product Consistency | Variable | Consistent |

These improvements not only boosted throughput but also significantly enhanced overall racket quality, thereby meeting both internal production goals and market expectations.

For manufacturing engineers and production managers looking to implement or upgrade thermoforming processes for padel rackets, here are some best practices:

• Fine-Tune Mold Designs: Regularly update mold designs to account for new materials or design changes. A well-designed mold ensures minimal post-processing.

• Invest in Skilled Training: Ensure that operators and technicians understand the nuances of thermoforming processes and the importance of precise temperature control.

• Document Process Parameters: Keeping a detailed record of all process parameters can be beneficial for troubleshooting and continuous improvement.

• Schedule Preventative Maintenance: Regular checks on heating systems, molds, and cooling units prevent unexpected downtime and ensure smooth production flows.

• Collaborate with Material Suppliers: Close communication with material suppliers, such as those providing high-grade carbon fiber and fiberglass, can lead to innovations in material handling and formulation.

• Monitor Industry Trends: Stay updated with industry trends and technological advancements in thermoforming, as innovations can offer significant improvements in both quality and cost-efficiency.

Thermoforming techniques serve as an essential pillar in modern padel racket production, keeping pace with the evolving demands for performance and customization. By understanding the process—right from material selection through to post-processing—manufacturers can significantly enhance production efficiency, reduce waste, and guarantee a product that meets high durability standards.

For decision-makers in sports equipment manufacturing, the key takeaways are:

• Adopt advanced automation and control systems to maintain consistent manufacturing conditions.

• Invest in R&D focused on material innovations, ensuring that each padel racket offers top performance.

• Use detailed quality control measures and regular maintenance schedules to further reduce variability and defects.

Integrating these strategies can help your facility not only meet current production challenges but also prepare for future advancements in the thermoforming arena. As you evaluate your own processes, consider these insights as a catalyst for transformative improvements in product durability and operational efficiency.

• What is the process of thermoforming pickleball paddles?

Thermoforming pickleball paddles involves heating a plastic sheet until it becomes pliable, then molding it into the desired paddle shape before cooling it down. This process results in a lightweight yet sturdy paddle with excellent control and power.

• Are thermoformed pickleball paddles better?

Thermoformed pickleball paddles, crafted using controlled heat and pressure, offer enhanced durability and precise engineering. This method ensures that the paddle is designed for longevity and optimized performance, making them a reliable choice for players.

• What is the best material for a padel racket?

The core material for a padel racket is crucial for balancing performance and durability. Materials like EVA foam are generally firmer and more resilient, while soft foam offers enhanced playability. Manufacturers choose the best material based on the desired balance between power, finesse, and overall racket longevity.

-

Thermoforming: Click to read an article explaining the fundamentals of thermoforming, its technical benefits, and its role in modern manufacturing processes. ↩ ↩

-

Fiberglass: Click to read an article detailing fiberglass properties, its applications in composite manufacturing, and cost-effective production methods. ↩ ↩ ↩2

-

Carbon fiber: Click to read an article about carbon fiber composites, highlighting their superior strength, durability, and use in high-performance products. ↩ ↩ ↩2

-

IoT: Click to read an article on the Internet of Things (IoT) in industrial automation, covering sensor integration and real-time monitoring for optimized production. ↩ ↩

-

Non-destructive Testing: Click to read an article about non-destructive testing methods, their importance in quality assurance, and techniques used to detect internal defects. ↩ ↩