The article quickly answers: Effective quality control in high-volume padel rackets1 production relies on a systematic approach that combines material precision, process optimization2, and continuous monitoring to ensure every racket meets the highest standards. This article explains how strategic quality control measures and process improvements enable manufacturers to sustain performance, durability, and consistency while scaling production.

High-volume production of padel rackets1 poses unique challenges that go beyond simple assembly line procedures. For quality assurance managers, production engineers, and supply chain coordinators, ensuring that every racket is manufactured according to exacting standards is critical. The competitive global market, evolving performance requirements, and increasing customization demands all drive the need to implement robust quality control systems.

In this article, we outline proven strategies and practical steps for successful quality control in large-scale production. We focus on key factors such as material selection, precision production processes, real-time inspection, and continuous feedback loops—all of which are essential to meeting the demands of today’s market.

Padel rackets are manufactured from a variety of materials, including fiberglass and different grades of carbon fiber3 (3k, 12k, and 18k). Each material offers unique performance characteristics. For instance, carbon fiber provides a lightweight yet durable structure but is more sensitive to production inconsistencies. Material variability can lead to performance disparities between rackets, potentially affecting factors such as balance, durability, and overall player satisfaction.

In a high-volume operation, even minor deviations in the production process can lead to significant quality issues. With various production types—such as Diamond, Round, Teardrop, and even fully customized shapes—the risk of discrepancies increases if comprehensive quality control measures are not in place. Process adjustments, rapid prototyping, and custom printing require special attention to detail to maintain product integrity throughout the production lifecycle.

Maintaining a high level of product consistency means that all machinery must be regularly calibrated. Automated inspection systems, along with manual quality checks, are indispensable. A slight misalignment in cutting or molding equipment can result in component misfits, affecting the final product quality. Therefore, uninterrupted calibration and upkeep of quality control technology are fundamental to success.

To address these challenges, manufacturers can employ a range of quality control strategies. Below, we summarize the most effective approaches that have consistently shown results in the production of padel rackets:

- Supplier Quality Assurance: Work closely with material suppliers to ensure that raw materials (fiberglass and carbon fiber) meet detailed specifications. Implement incoming quality checks that validate the consistency of fiber layout, resin quality, and other critical properties.

- Material Traceability: Implement traceability protocols that track materials from supplier to final product. This approach helps quickly pinpoint sources of inconsistencies and enables corrective actions.

The production process should be continuously monitored and refined. The following table summarizes common process optimization steps:

| Process Stage | Key Quality Control Measures | Potential Challenges |

|---|---|---|

| Material Preparation | Verify material quality; ensure proper storage conditions | Material degradation, impurity variations |

| Molding & Forming | Regular calibration of molding machines; temperature control | Operator error, equipment wear |

| Curing and Hardening | Monitor curing cycles; use sensors for process timing | Inconsistent temperature control |

| Custom Printing & Finishing | Ensure design alignment; verify printed logos and colors with templates | Drift in alignment, color mismatches |

| Final Assembly & Inspection | Conduct both automated and manual inspections; use statistical process control (SPC) | Misalignment, assembly faults |

3. Real-Time Monitoring4 and Continuous Feedback

- Automation & Sensors: Invest in automated inspection systems that incorporate sensors for real-time data acquisition. These systems can detect deviations and trigger alerts for immediate corrective action.

- Data Analytics: Use collected data to refine quality control benchmarks. By leveraging data analytics, manufacturers can identify trends, predict potential issues, and optimize production schedules.

4. Standard Operating Procedures (SOPs)5 and Regular Training

- SOPs: Document and update detailed operating procedures that reflect the best practices in quality control. This ensures consistency regardless of personnel changes.

- Employee Training: Regularly train staff on quality assurance techniques and the proper use of equipment. A well-trained workforce is fundamental to maintaining high production standards.

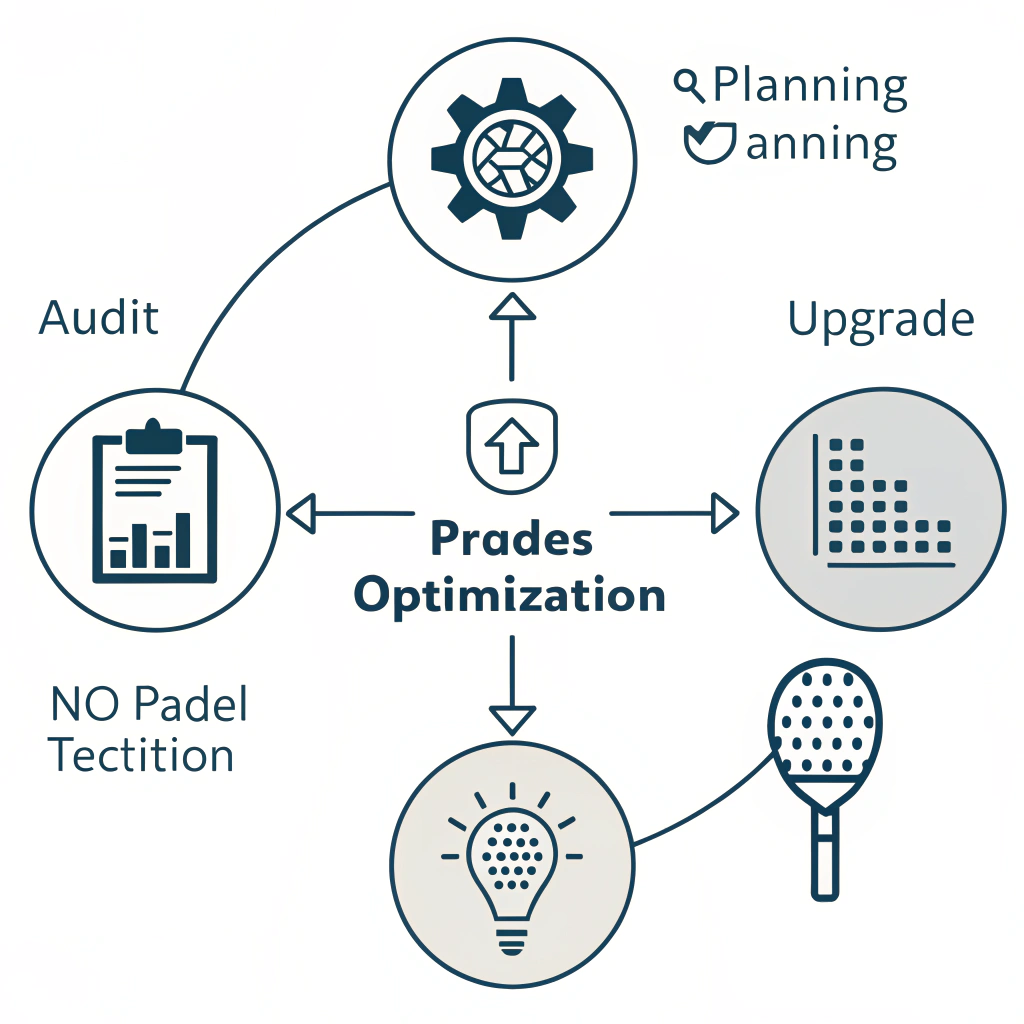

Successful implementation of quality control measures often involves a combination of technology upgrades, staff training, and process standardization. Below are the steps required to integrate these strategies:

Begin with a complete audit of the current production process. Identify bottlenecks, areas of high variability, or recurring issues in product quality. This diagnostic phase should involve:

- Reviewing production logs and quality data.

- Conducting onsite inspections.

- Interviewing production and quality control teams.

Based on the audit, draw up a targeted plan that addresses identified issues. Set clear, measurable objectives:

- Reduce defect rates by a specific percentage.

- Increase machine uptime through precise calibration schedules.

- Implement real-time monitoring systems in critical production stages.

Integrate advanced monitoring technologies, such as automated quality control systems and inline sensors. These systems provide valuable feedback and help spot deviations early. For example:

- Automated systems can measure the thickness, weight, or material composition of every component.

- Sensors in molding machines ensure that temperature and pressure remain within optimal ranges.

Create and implement Standard Operating Procedures (SOPs)5 that all employees must follow. These documents should cover:

- Material handling protocols.

- Equipment operation and maintenance.

- Inspection and quality control checklists.

Quality control is not a one-time setup; it is an ongoing process. Regular training sessions help employees stay updated on the latest best practices and equipment updates. Adopt a continuous improvement mindset, routinely reassessing production processes to identify further optimization opportunities.

At NEX Padel, we have implemented many of these strategies to ensure that our padel rackets consistently meet high quality and performance standards. Here are some key insights from our experience:

NEX Padel maintains strict supplier qualification processes. Every batch of carbon fiber3 or fiberglass undergoes rigorous testing upon arrival. This upfront scrutiny reduces the risk of material-related defects later in the production process.

Our approach to customization—whether it’s adjusting racket shapes (Diamond, Round, Teardrop) or adding personalized logos on hand grips—relies on a flexible yet standardized production system. By integrating automated tracking systems and robust SOPs, our engineers and quality team ensure that every custom order is fulfilled with consistent quality.

Using real-time data from our production lines, we routinely update our production parameters. This data-driven approach allows us to maintain consistency even in high-demand scenarios where production speed could potentially compromise quality. Our client feedback loops drive periodic reviews and enhancements to our quality control processes.

NEX Padel places enormous emphasis on maintaining production equipment. Scheduled calibrations, combined with preventive maintenance practices, help minimize downtime and reduce the chances of equipment-related quality issues.

Implementing robust quality control procedures in padel racket production is not only about product excellence. There are several additional benefits:

- Improved Brand Reputation: High-quality products build trust with end users and strengthen the brand’s market positioning.

- Reduced Waste and Rework: By detecting errors early, manufacturers can reduce material waste and limit the costs associated with rework.

- Increased Production Efficiency: Streamlined and well-monitored processes lead to faster turnaround times and a more predictable production schedule.

- Enhanced Customer Satisfaction: Ultimately, reliable quality control produces products that competitors struggle to match, translating into better customer experiences and repeat business.

Ensuring high quality in large-scale padel racket production requires a multi-faceted approach—one that integrates advanced material management, process optimization, real-time monitoring, and continuous improvement practices. Manufacturers must:

• Conduct thorough audits to understand process bottlenecks and quality challenges.

• Implement standardized operating procedures and invest in automation technologies.

• Train staff regularly and maintain equipment meticulously to ensure performance consistency.

For companies seeking to optimize their production quality and scale up without compromise, the strategies highlighted in this article provide a practical framework. Explore your current processes, identify key areas for improvement, and take actionable steps towards implementing robust quality control measures. In doing so, you’ll not only enhance product performance and consistency but also ensure that your production system remains reliable even under high-volume demands.

By adopting these practices, quality assurance managers and production engineers in the sports equipment manufacturing sector can remain confident that every padel racket leaving the factory meets precise industry standards, solidifying your brand’s reputation for excellence.

Q1: What are the main quality challenges in high-volume padel racket production?

A1: The main challenges include managing material variability (such as differences in carbon fiber and fiberglass), maintaining process consistency during rapid production runs, ensuring precise customizations, and avoiding equipment calibration issues that can lead to inconsistencies.

Q2: How can process optimization improve production efficiency in padel racket manufacturing?

A2: Process optimization streamlines production steps through automation and real-time monitoring. It reduces errors, minimizes rework, and allows for immediate corrective actions. This results in faster production cycles and more consistent product quality, even with high-volume demands.

Q3: What role does advanced material selection play in quality assurance for padel rackets?

A3: Advanced material selection—choosing the right grade of carbon fiber or fiberglass—ensures a balance between durability, performance, and weight. This is a core component of quality assurance as it directly affects the final product's reliability and consistency across high-volume production runs.

-

padel rackets: Read this article to gain insights into the specific challenges and production nuances of padel racket manufacturing, including design standards and quality benchmarks. ^↩ ↩ ↩2

-

process optimization: Discover strategies to enhance efficiency in manufacturing processes through systematic improvements, cost-reduction tactics, and quality assurance measures. ^↩ ↩

-

carbon fiber: Click here to explore detailed information on carbon fiber’s properties, its applications in manufacturing, and why its quality control is crucial in high-performance sporting goods. ^↩ ↩ ↩2

-

real-time monitoring: Understand how integrating live data acquisition and sensor technology can preemptively detect deviations in production, helping to maintain quality control in fast-paced manufacturing environments. ^↩ ↩

-

Standard Operating Procedures (SOPs): Learn about the importance of standardized processes to ensure uniformity across operations, mitigate risks, and maintain high standards in production. ^↩ ↩ ↩2