Padel rackets achieve lasting durability when optimal materials and precise manufacturing processes work in tandem. In essence, the durability and longevity of a padel racket are driven by its composite material selection—ranging from glass fiber1 to various grades of carbon fiber (3K, 12K, 18K)2—and the implementation of advanced production techniques that enhance structural integrity and impact resistance.

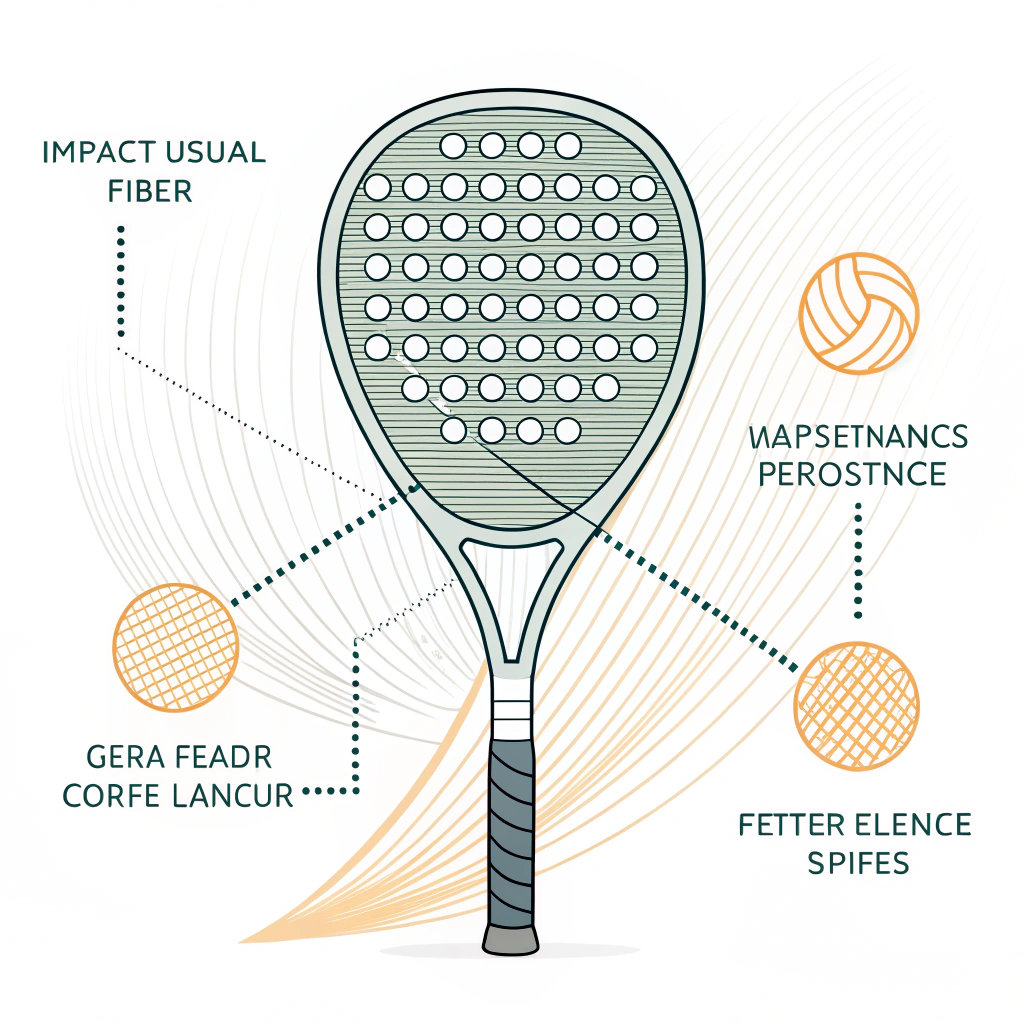

For technical product managers and design engineers, the central challenge is how to balance performance with durability in padel rackets. The primary concerns include impact resistance, fatigue performance, and structural integrity over prolonged use. This balance is particularly crucial when selecting composite materials and customizing racket designs for various performance needs.

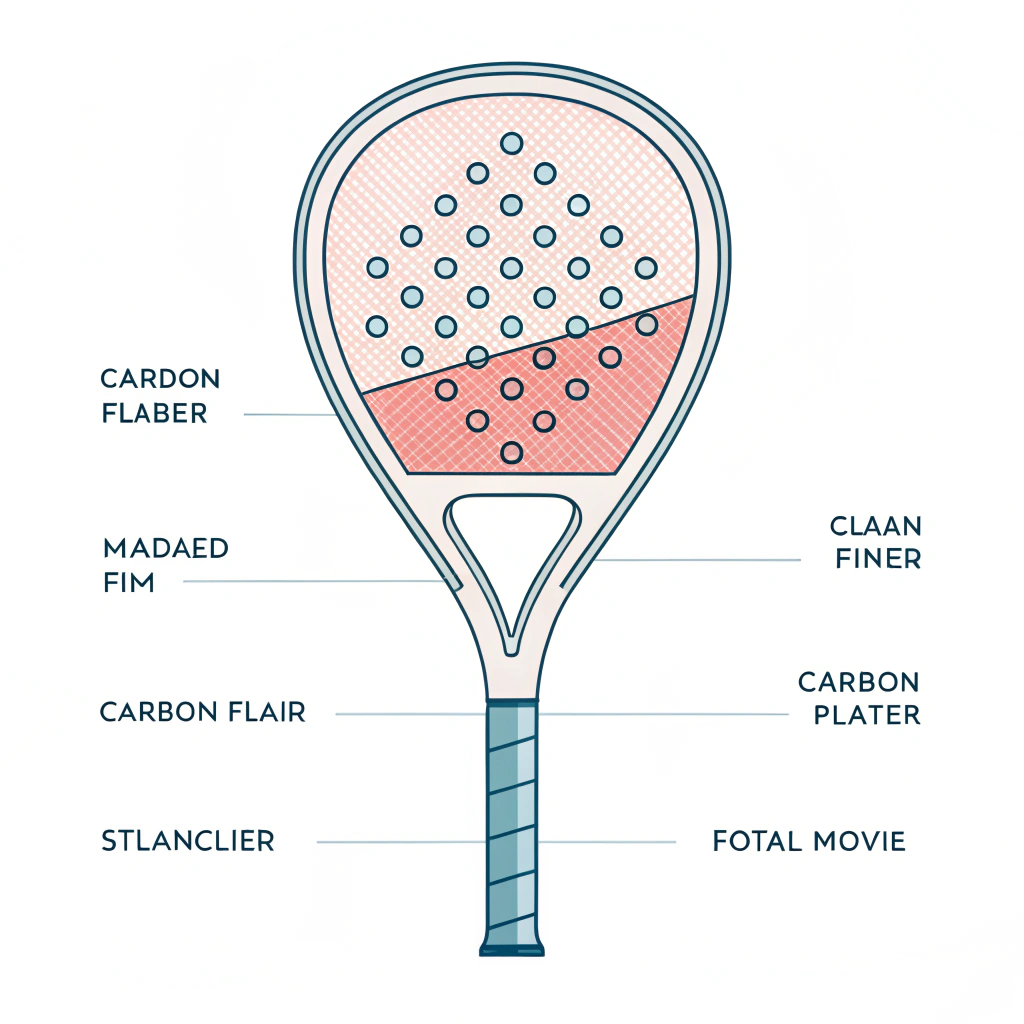

Padel rackets are subject to a range of dynamic loads and impacts. Each component—from the frame to the grip—must endure repetitive stress. The material science3 behind the racket is the foundation for its quality and lifespan. With advanced materials like carbon fiber and glass fiber, manufacturers can tailor both stiffness and flexibility, directly influencing durability.

One of the essential aspects of padel racket durability is the choice of composite materials:

- Glass Fiber: Known for its excellent elasticity, glass fiber provides a degree of shock absorption, making it suitable for the racket's core structure. However, its impact resistance may be lower compared to carbon fiber composites.

- Carbon Fiber (3K, 12K, 18K):

- 3K Carbon Fiber: Offers a balanced performance with adequate stiffness and durability.

- 12K and 18K Carbon Fiber: Provide higher stiffness and improved impact resistance, though they might result in a slightly heavier racket profile if not optimized.

Advanced production techniques allow for tailoring the layers and orientation of these fibers. The combination of fibers helps mitigate fatigue and reduce the likelihood of micro-cracks over repeated impacts. The correct ratio and layering can significantly extend the racket’s service life while maintaining peak performance.

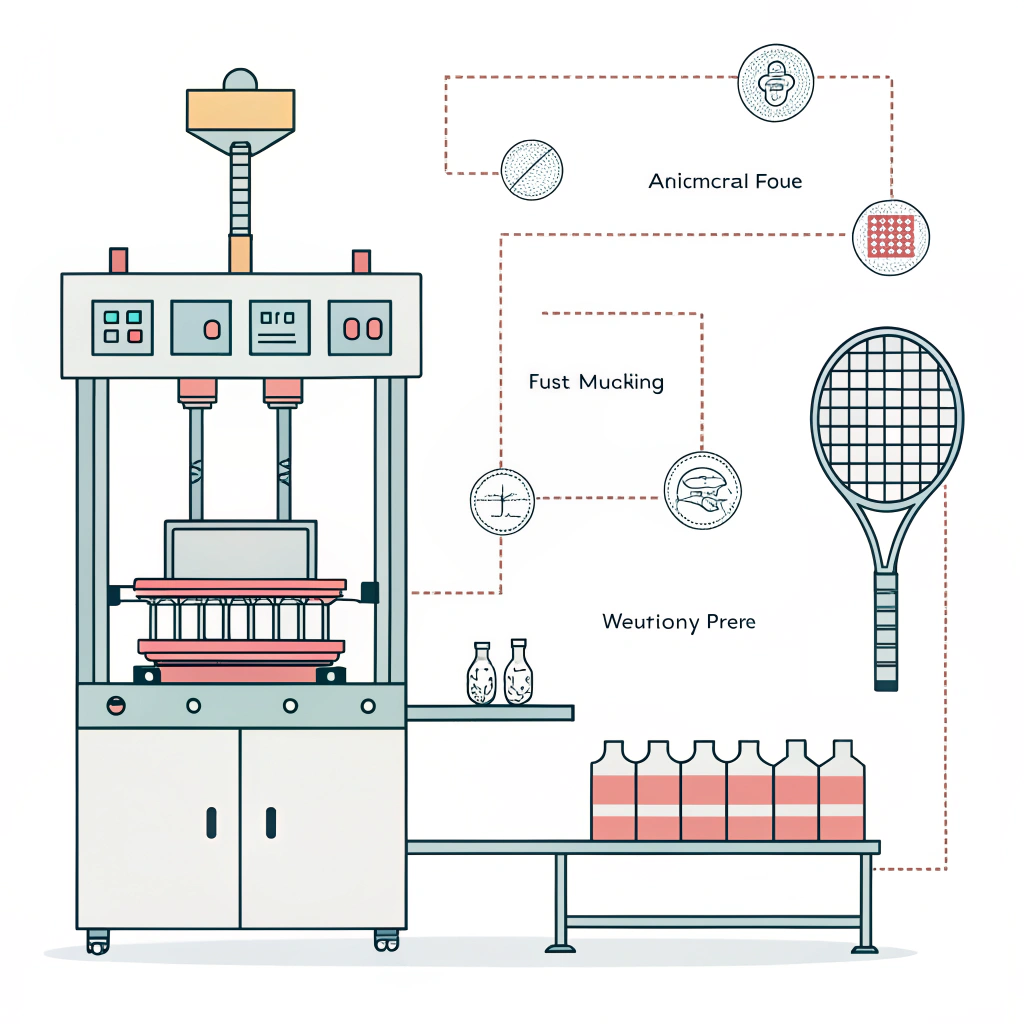

Modern manufacturing methods such as automated resin transfer molding4 and high-pressure curing are central to realizing the potential of composite materials. These processes ensure:

- Uniform resin distribution: Critical for consistent impact resistance.

- Precise mold design: Essential for achieving the optimal balance between stiffness and flexibility.

- Quality Control Checks: Vital at every stage to ensure that the final product meets specific durability standards.

Our company, NEX Padel, applies these techniques to produce padel rackets that not only perform at the highest levels but also offer a high degree of customization. Whether it is the diamond, round, or teardrop shapes—or even fully customized designs—the production processes ensure that each racket provides maximum durability with excellent performance metrics.

Below is a detailed checklist of solutions to achieve superior durability in padel rackets:

| Step | Description | Key Considerations |

|---|---|---|

| Material Selection | Choose between glass fiber and various grades of carbon fiber based on desired properties. | Impact resistance, weight, stiffness, cost, and customization needs. |

| Layer Configuration | Optimize the layering configuration to balance shock absorption with rigidity. | Fibers should be arranged to mitigate stress accumulation. |

| Advanced Molding Techniques | Employ methods like resin transfer molding and high-pressure curing for superior integration. | Ensures uniformity and minimizes air pockets or weak spots. |

| Precision Customization | Utilize high-precision molds tailored for diamond, round, or teardrop designs. | Fine-tuning dimensions and shapes for optimal ergonomics and performance. |

| Fatigue and Impact Testing | Implement accelerated fatigue testing5 and impact resistance experiments to evaluate longevity. | Data-driven quality checks to optimize and iterate on design improvements. |

| Quality Control | Incorporate robust quality control measures throughout the production process. | Regular audits and calibration of machines ensure consistency. |

The table above provides a clear framework to help manufacturers or procurement specialists understand where improvements can be made, ensuring that every design choice results in a padel racket that stands the test of time.

Repeated impacts can create micro-cracks in composite materials, which accumulate over time, leading to reduced performance. These issues typically emerge due to:

- Insufficient Resin Curing: Unoptimized curing processes may leave voids or weak bonding areas.

- Improper Fiber Orientation: Misalignment can lead to stress concentration.

- Environmental Factors: Temperature fluctuations and humidity may accelerate material degradation.

Each of these factors necessitates a precise balance between innovation, engineering design, and rigorous testing.

Modern techniques aim to mitigate these common issues:

- Accelerated Curing Processes: High-pressure and temperature-controlled curing processes ensure a robust bond between fibers and resin.

- Thermal and Environmental Simulation Testing: Simulates real-world conditions to assess long-term performance under diverse weather conditions.

- Iterative Prototyping: Rapid prototyping combined with performance feedback helps refine each design iteration before full-scale production.

These methods not only enhance the longevity of the racket but also ensure that the final product meets both competitive and recreational standards.

In one recent project at NEX Padel, engineers sought to improve the impact resistance of our teardrop-designed racket. The process involved:

- Reevaluating the proportion of 12K and 18K carbon fiber layers to boost stiffness.

- Adjusting the resin formulation to better bond with both glass and carbon fibers.

- Implementing incremental fatigue tests to simulate thousands of game impacts.

- Rackets produced with optimized fiber layering showed a 20% improvement in impact resistance.

- Test results demonstrated reduced instances of micro-cracks, confirming the efficacy of revised curing techniques.

- The final designs achieved a superior balance between weight and durability, meeting both performance and longevity expectations.

This case study highlights how targeted adjustments in material composition and manufacturing processes can significantly influence the lifecycle performance of padel rackets.

In summary, the durability and lifespan of a padel racket are deeply intertwined with the quality of materials and precision in manufacturing processes. To maximize durability, manufacturers and procurement specialists should:

- Focus on material selection, choosing between glass fiber and various carbon fiber variants based on specific performance requirements.

- Optimize layer orientation and resin curing technology to prevent micro-cracks and extend durability.

- Incorporate rigorous testing protocols to simulate real-use conditions and refine design choices.

- Consider customization options that allow adjustments for different play styles and environmental conditions.

For technical product managers and design engineers, these insights can guide future design innovations and procurement strategies. Leveraging advanced manufacturing techniques not only enhances performance but also ensures a competitive edge in the emerging global padel racket market.

By aligning engineering principles with innovative production methods, companies like NEX Padel are poised to deliver products that meet both the demands of high-level performance and the long-term expectations of durability. For procurement specialists, understanding these technical details is essential to selecting suppliers that offer both quality and reliability in their padel equipment products.

As the industry continues to evolve, staying informed about the latest trends in composite material science and manufacturing techniques will be critical. We encourage you to engage with further technical literature, attend specialized trade shows, and consult with materials experts to continue enhancing your product portfolios.

People Also Ask

-

What factors affect padel racket durability?

Durability is affected by the choice of composite materials, fiber orientation, resin curing techniques, and the rigorousness of quality control during manufacturing. Each element contributes to the racket's impact resistance and longevity. -

How does the grade of carbon fiber impact racket performance?

Different grades of carbon fiber, such as 3K, 12K, and 18K, influence the balance between stiffness and flexibility. Higher grades typically offer better impact resistance but may require fine-tuning to prevent added weight. -

What manufacturing processes enhance the durability of padel rackets?

Advanced techniques like automated resin transfer molding, high-pressure curing, and precision custom molding are key to achieving uniform material distribution, optimal fiber bonding, and thorough fatigue testing—all contributing to enhanced durability.

-

glass fiber: Click to learn how glass fiber’s elastic properties contribute to shock absorption and overall durability in composite structures. ↩

-

carbon fiber (3K, 12K, 18K): Click to explore the differences in carbon fiber grades and how they affect stiffness, weight, and impact resistance. ↩

-

material science: Click to delve into the fundamentals of material science and its role in optimizing performance and longevity in sports equipment. ↩

-

automated resin transfer molding: Click to understand how automated resin transfer molding ensures uniform resin distribution and improves structural integrity during manufacturing. ↩

-

accelerated fatigue testing: Click to review the methodologies behind accelerated fatigue testing and how it simulates long-term usage to improve product durability. ↩