The Impact of Core Density1 on Padel Racket Performance and Durability

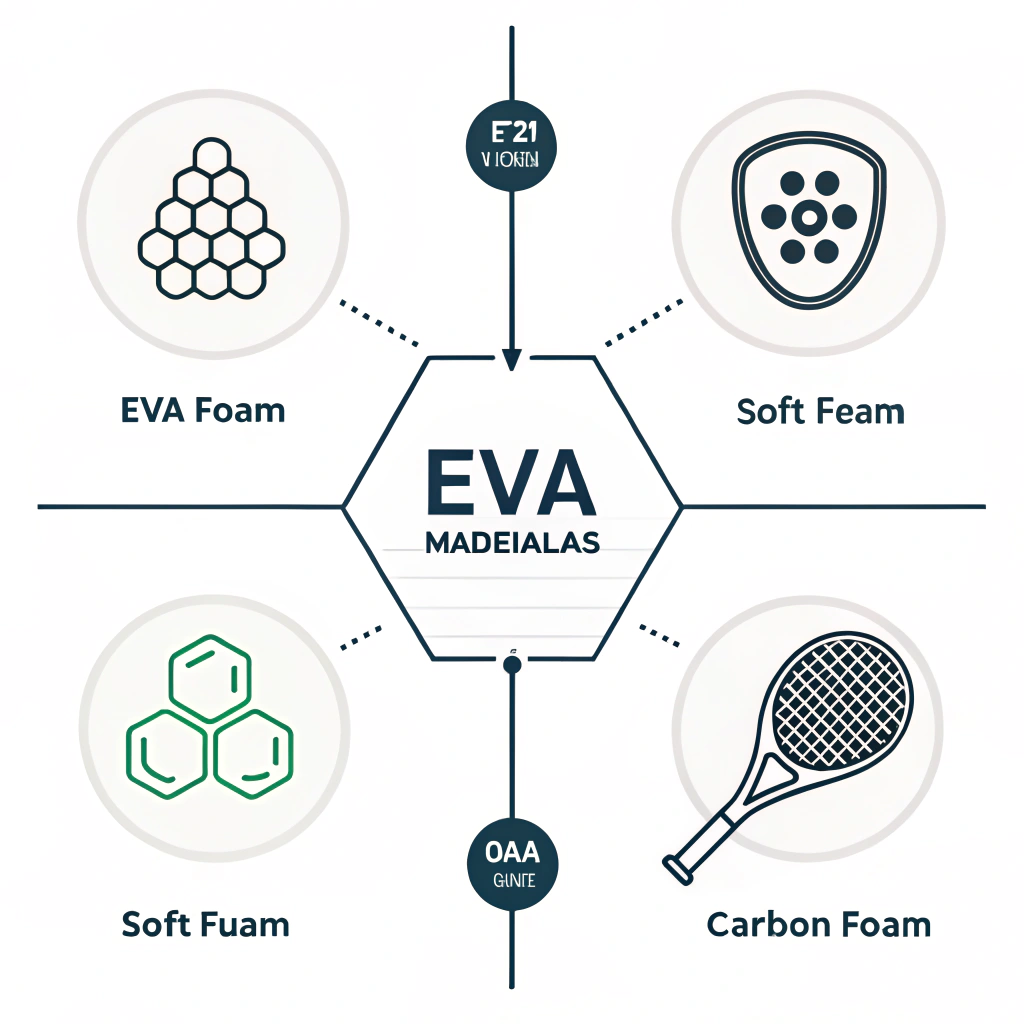

A quick answer: The core density of a padel racket plays a crucial role in balancing power, control, and durability. By carefully choosing materials and production techniques—such as opting for EVA foam2 for a firmer response or softer foam for enhanced feel—manufacturers like NEX Padel can tailor performance to meet the needs of different player profiles and market segments.

In today’s competitive padel equipment market, product development managers and procurement specialists must understand the technical nuances of racket design. One of the critical factors determining a racket’s performance is its core density. As manufacturers push the boundaries of high-performance sports equipment, the choice of materials and the techniques used to produce them are more essential than ever. In this article, we dissect the impact of core density on padel racket performance, exploring key materials, weight considerations, and technical specifications that influence the final product.

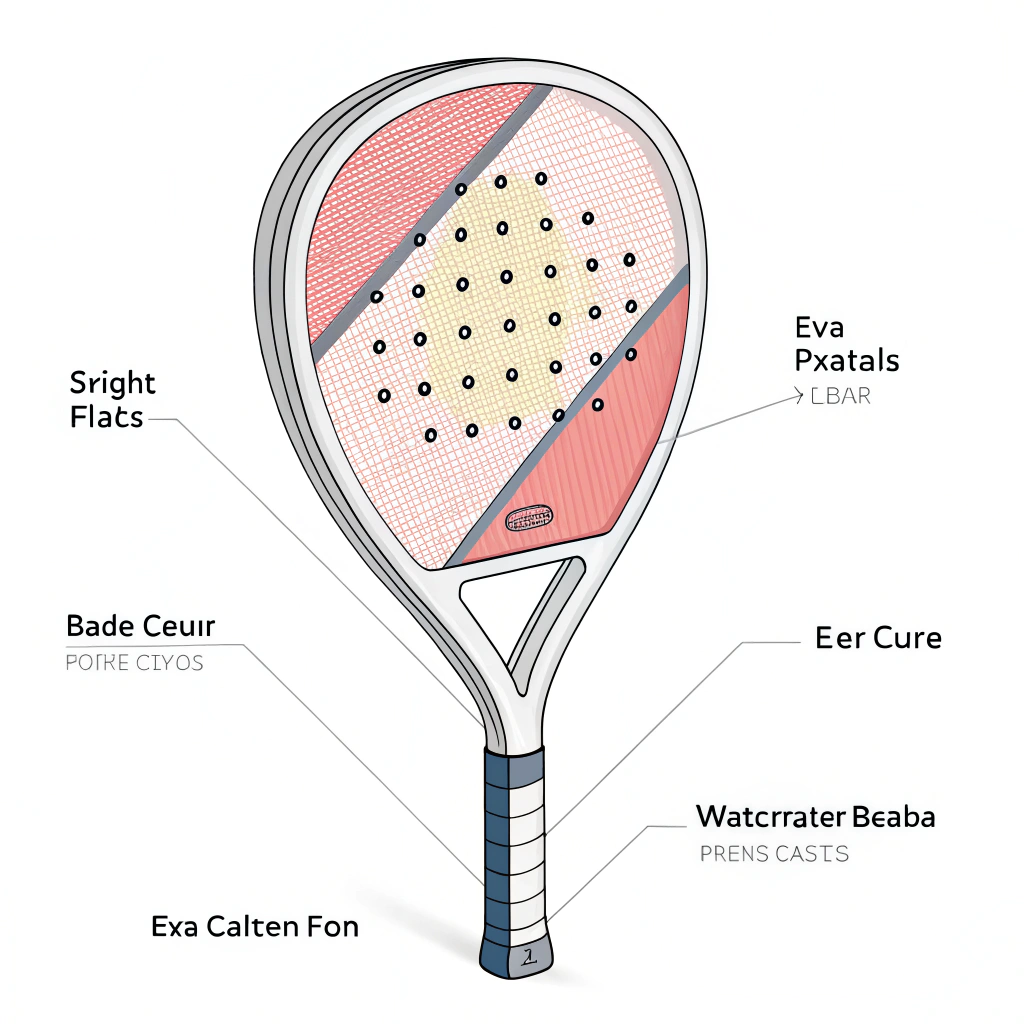

The core of a padel racket is more than just a filler; it is the heart of energy transfer, vibration damping, and overall durability. Manufacturers have experimented with various types of cores such as EVA (ethylene-vinyl acetate) foam and softer foams, each bringing its own set of benefits. EVA foam, known for its firmness and resistance, offers a balance between power and finesse. In contrast, softer foams tend to provide better shock absorption and control.

At NEX Padel, our production processes allow customization down to the core density level, ensuring that each padel racket can meet specific performance profiles. By selecting from materials like carbon fiber variants (3k Carbon Fiber3, 12k Carbon Fiber4, 18k Carbon Fiber5) combined with tailored core densities, we create rackets that deliver consistent performance under different playing conditions.

High-performance padel rackets must satisfy several performance criteria such as durability, power transmission, vibration damping, and player comfort. Selecting the proper core density is challenging because it influences several interconnected parameters. For example, a denser core can translate into higher power but might also introduce more vibrations. On the other hand, a softer core can offer excellent control and comfort with a slight trade-off in power.

The dilemma is rooted in the physical behavior of different core materials. The rigidity versus flexibility spectrum is determined by the constituents of the core. EVA, being a more resilient material, tends to preserve energy efficiency during impacts. However, materials with a lower density absorb more energy, which can diminish power while boosting control. Additionally, the layered structure of the racket—using carbon fibers of varying thread counts such as 3k, 12k, and 18k—further complicates the equation by influencing overall stiffness and performance dynamics.

To fully appreciate these trade-offs, it’s essential to examine the key attributes affected by core density:

- Power Transfer: A denser core can contribute to greater energy return upon ball impact.

- Vibration Dampening: Softer core materials tend to better absorb shocks, reducing the strain on a player’s arm.

- Durability: Harder cores (combined with rigid carbon fiber layers) often show increased wear resistance but may be less forgiving during high-impact situations.

- Control: A moderated core density often results in a more predictable racket behavior, allowing for enhanced precision during play.

Given the complexity, manufacturers must adopt a robust framework for material selection and testing. Below are several practical approaches and considerations that NEX Padel and other leading manufacturers utilize:

Rigorous testing procedures assess various foam types and carbon fiber combinations under simulated play conditions. By systematically testing different core configurations, we can determine the best combination for specific playing styles.

Modern production methods allow for rapid prototyping and precise control over material thickness and density. At NEX Padel, our flexibility in using 3k, 12k, and 18k carbon fibers, along with custom core densities, ensures that both high performance and reliability are maintained.

Understanding that performance needs vary among players, we offer fully customizable designs. Our three primary shapes—Diamond, Round, and Teardrop—can be paired with different core densities and material specifications. This customization extends to handle components such as hand grip and handle cover, which can also carry a custom logo, ensuring brand consistency and product excellence.

Below is a table summarizing the main attributes of different core materials and carbon fiber types used in padel rackets:

| Material/Composite | Core Density Characteristics | Flexibility | Power Transmission | Vibration Damping | Durability |

|---|---|---|---|---|---|

| EVA Foam | Higher density, firm feel | Moderate | Good energy return | Moderate | High resistance |

| Soft Foam | Lower density, softer feel | High | Less power, more control | Excellent | Moderate |

| 3k Carbon Fiber | Lower thread count, more flexible | High | Smooth ball absorption | Fair | Good durability |

| 12k Carbon Fiber | Higher rigidity than 3k | Moderate | Increased power | Moderate | High durability |

| 18k Carbon Fiber | More threads; flexible yet stable | Balanced | Good control and power blend | Excellent | Very high durability |

This table is a tool that helps product development managers quickly assess what type of core might work best for specific performance goals. For example, if durability and power are paramount, a combination of EVA foam with 12k carbon might be ideal. Conversely, for players prioritizing control and shock absorption, a softer foam integrated with 18k carbon could be a superior choice.

Besides the core density and material composition, the overall weight of the padel racket plays a significant role in performance. A lighter racket is generally easier to swing and is less taxing on the player’s arm, especially during long matches. However, weight can also impact power. Typically, a lighter racket paired with a specific core density may provide more maneuverability and reduce fatigue, while a heavier racket might offer greater impact force for repeated powerful hits.

By understanding the interplay between core density and overall racket weight, manufacturers can fine-tune racket designs to suit various player profiles. For instance:

- Lighter Rackets: Favor optimal energy efficiency and require less effort, ideal for players with less upper body strength.

- Heavier Rackets: Enhance power generation but require sturdier construction and may result in increased stress on the arm over extended play sessions.

At NEX Padel, we leverage precise weight balancing in tandem with advanced material selection to create rackets that excel in performance regardless of the player’s physical attributes.

Leading sports equipment brands have utilized technical insights on core density to innovate and excel in the padel market. A comparative study revealed that customizing the core density not only improved on-court performance but also boosted customer satisfaction by providing a tailored playing experience. The data indicated that:

- Rackets with a firmer core aided in transferring energy more efficiently, making them ideal for aggressive play.

- Rackets with a softer core resulted in lower vibration levels, reducing the risk of arm injuries during extensive play.

NEX Padel’s production process, which uses high-grade materials combined with state-of-the-art testing methods, is a testament to the importance of these technical advancements. Our constant collaboration with industry-leading sports brands has fostered innovations in both design and production efficiency, resulting in high-performance rackets that meet global standards.

In summary, understanding and optimizing core density is essential for enhancing the overall performance and durability of padel rackets. To make an informed material selection:

- Review the balance required between power and control, and choose a core material accordingly.

- Analyze weight factors in conjunction with core density to ensure an optimal swing experience.

- Utilize comparative data, such as the table above, to decide which materials best meet your product’s performance demands.

- Consider customization options that align with market expectations, ensuring that every racket meets both technical standards and brand identity.

For procurement specialists and product development managers, the insight into core density provides a strategic tool for product differentiation. As the market for high-performance sports equipment grows, manufacturers who invest in precise material engineers and tailor-made production techniques will lead the field in delivering performance and durability.

Embrace these data-driven insights, consult with your manufacturing partners, and ensure that your padel rackets are built to exceed the dynamic demands of today’s players.

People Also Ask

Q: What is the best core for a padel racket?

A: The best core for a padel racket often involves using EVA foam, as it provides a firm, balanced structure that offers a good mix of power and finesse. This firmness contributes to efficient power transmission while ensuring durability during play.

Q: Is a lighter or heavier padel racket better?

A: Lighter rackets are generally easier on the arm and offer improved maneuverability, making them ideal for players seeking reduced fatigue. However, heavier rackets can deliver greater power for those with sufficient upper body strength, as the added weight helps increase the impact force.

Q: Is 18K carbon harder than 12K?

A: While 18K carbon fabric is more flexible due to its higher number of threads, the 12K variant tends to be more rigid, providing increased power in hitting. This difference allows manufacturers to choose the appropriate carbon type based on desired racket performance characteristics.

-

Core Density: Click to explore an in-depth explanation of the significance of core density in sports equipment design, including how it influences energy transfer, vibration damping, and overall durability. ↩

-

EVA foam: Click to learn more about EVA foam, its material properties, and why it is widely used in high-performance sporting goods for achieving a balance between firmness and shock absorption. ↩

-

3k Carbon Fiber: Click to understand the characteristics of 3k carbon fiber, its typical applications in sports equipment, and how its lower thread count contributes to flexibility and performance. ↩

-

12k Carbon Fiber: Click to dive into the role of 12k carbon fiber in racket construction, highlighting its increased rigidity and how it enhances power transmission in high-impact sports equipment. ↩

-

18k Carbon Fiber: Click to explore how 18k carbon fiber achieves a balance between flexibility and stability, and why its higher thread count makes it ideal for improving racket control and durability. ↩